52896WA Advanced Diploma of Civil and Structural Engineering (Materials Testing)

Investigation of the properties of construction materials, the principles which…Read moreGraduate Diploma of Engineering (Safety, Risk and Reliability)

The Graduate Diploma of Engineering (Safety, Risk and Reliability) program…Read moreProfessional Certificate of Competency in Fundamentals of Electric Vehicles

Learn the fundamentals of building an electric vehicle, the components…Read moreProfessional Certificate of Competency in 5G Technology and Services

Learn 5G network applications and uses, network overview and new…Read moreProfessional Certificate of Competency in Clean Fuel Technology - Ultra Low Sulphur Fuels

Learn the fundamentals of Clean Fuel Technology - Ultra Low…Read moreProfessional Certificate of Competency in Battery Energy Storage and Applications

Through a scientific and practical approach, the Battery Energy Storage…Read more52910WA Graduate Certificate in Hydrogen Engineering and Management

Hydrogen has become a significant player in energy production and…Read moreProfessional Certificate of Competency in Hydrogen Powered Vehicles

This course is designed for engineers and professionals who are…Read more

This manual covers the fundamental concepts and will provide you with a clear understanding of the design and engineering principles used in plant layout and piping design.

Practical Process Plant Layout and Piping Design

By N.S. Nandagopal (Nanda)

Rev 5.1

Website: www.idc-online.com

E-mail: idc@idc-online.com

IDC Technologies Pty Ltd

PO Box 1093, West Perth, Western Australia 6872

Offices in Australia, New Zealand, Singapore, United Kingdom, Ireland, Malaysia, Poland, United States of America, Canada, South Africa and India

Copyright © IDC Technologies 2011. All rights reserved.

First published 2009

All rights to this publication, associated software and workshop are reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means electronic, mechanical, photocopying, recording or otherwise without the prior written permission of the publisher. All enquiries should be made to the publisher at the address above.

Disclaimer

Whilst all reasonable care has been taken to ensure that the descriptions, opinions, programs, listings, software and diagrams are accurate and workable, IDC Technologies do not accept any legal responsibility or liability to any person, organization or other entity for any direct loss, consequential loss or damage, however caused, that may be suffered as a result of the use of this publication or the associated workshop and software.

In case of any uncertainty, we recommend that you contact IDC Technologies for clarification or assistance.

Trademarks

All logos and trademarks belong to, and are copyrighted to, their companies respectively.

Acknowledgements

IDC Technologies expresses its sincere thanks to all those engineers and technicians on our training workshops who freely made available their expertise in preparing this manual.

Contents

Prelim i-x

1 Introduction to Process Plant Layout and Piping Design 1

1.1 Plant layout fundamentals 1

1.2 Procedures and workflow methods used in plant layout and piping design 6

1.3 Physical quantities and units in plant layout and piping design 9

1.4 Summary 12

Practical Exercise 1 13

2 Introduction to Chemical Processing Methods 15

2.1 Basic principles of chemical process technology 15

2.2 Process flow diagrams (PFDs) 20

2.3 Summary 27

Practical Exercise 2 28

3 Equipment Used in Process Plants 31

3.1 Introduction 31

3.2 Process equipment 32

3.3 Mechanical equipment 47

3.4 Summary 51

Practical Exercise 3 (Towers and Reactors) 53

4 Plant Layout and Plot Plans 55

4.1 Plant layout specifications 55

4.2 Plot plans 56

4.3 Summary 65

Practical Exercise 4 66

5 Piping and Instrumentation Diagrams (P&IDs), Control Valve Manifolds, Meter Runs 69

5.1 Piping and instrumentation diagrams (P&IDs) and their role in process plant layout and piping design 69

5.2 P&ID symbols and terminologies 70

5.3 Layout and components of control valve manifolds 76

5.4 Layout and components of flow meters 77

5.5 Summary 78

Practical Exercise 5 (P&IDs) 79

6 Plant Layout and Piping Design Documentation and Tools 81

6.1 Importance of documentation in plant layout and piping design 81

6.2 Equipment arrangement drawings 82

6.3 Equipment lists 84

6.4 Piping and instrumentation diagrams (P&IDs) 84

6.5 Piping line lists 84

6.6 Piping codes 86

6.7 Piping specification 89

6.8 Piping isometrics 91

6.9 Fabrication isos and bill of materials 94

6.10 Three dimensional (3D) models 96

6.11 Summary 98

Practical Exercise 6 99

7 Fundamentals of Piping 101

7.1 Fundamentals of piping 101

Practical Exercise 7 104

Practical Exercise 7 – Metric 107

8 Components of a Piping System 109

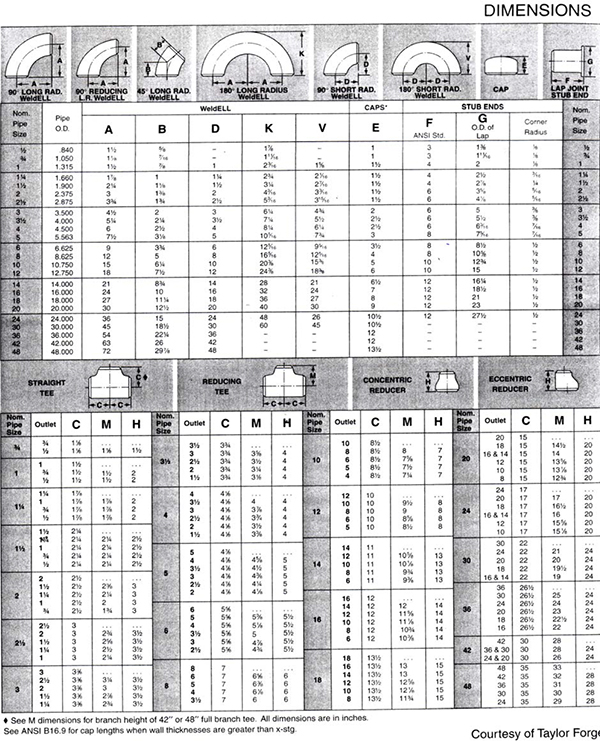

8.1 Fittings 109

8.2 Flanges 118

8.3 Valves 126

Practical exercises in Metric 133

8.4 Summary 139

9 Pipe Routing 141

10 Piping Materials 151

10.1 Introduction 151

10.2 Material classification system and specifications 152

10.3 Piping specifications 154

10.4 Material selection 154

10.5 Quality control and material certification 155

Appendix A Pipe Data and Fitting Dimensions 157

Post Course Test 173

This chapter provides a brief introduction to Process Plant Layout and Piping Design. The fundamental aspects of process plant layout and piping design are discussed. An overview of the procedures and workflow methods used in plant layout and piping design is also provided and the physical quantities and units commonly used are presented.

Learning objectives

- Understanding the fundamental aspects of process plants, plant layout and piping design.

- Understanding the procedures and the workflow methods used in designing process plants and piping systems.

- Understanding the physical quantities and units used in process plant layout and piping design.

1.1 Plant layout fundamentals

Process plants encompass all types of facilities involved in the chemical/physical processing of raw materials into desired finished products or intermediates for further processing. Examples of such processing facilities include the following:

- Refineries.

- Chemical/Petrochemical Plants.

- Fertilizer Plants.

- Offshore Processing Facilities.

- Power Plants.

- Pulp and Paper Mills.

- Food/Beverage Industries.

- Pharmaceutical Plants.

- Water Treatment Plants.

- Waste Treatment Facilities.

The processing facilities included in the preceding list play a vital role in meeting the basic needs of humanity. Therefore, a proper design, maintenance and operation of such facilities is necessary to ensure steady, dependable supply of materials and products required for comfortable and productive living in the contemporary modern world.

Process plants are complex facilities consisting of equipment, piping systems, instruments, electrical systems, electronics, computers and control systems. Figure 1.1 is a picture of a section of a refinery that illustrates the complexity of the equipment, piping and other entities.

A small section of a refinery showing equipment, piping system and other items.

The design of process plants is a complex team effort involving different disciplines of engineering: process (chemical), mechanical, piping, electrical, instrumentation, controls, materials and project. It also requires considerable management and coordination skills.

The objective is to design and construct a plant in a cost-effective manner that will meet the process requirements and client specifications and that will operate in a safe reliable manner. Other factors to be considered in the design of process plants are:

- Short design, engineering and construction schedules and getting the plant on stream as quickly as possible.

- Minimizing or even eliminating field rework, which significantly increases plant construction costs.

- Constructability.

- Maintainability.

- Operability.

- Satisfying environmental requirements.

- Minimizing costs.

Figure 1.2 illustrates the interaction and teamwork between different disciplines in the plant layout and piping design effort.

Plant Design and Piping Design Effort – Contributions from different disciplines

Tasks involved in plant layout and piping design

Plant Layout and Piping Design involve multiple tasks, which include:

- Development and refinement of “Plot Plans”. Plot plans are representations of precise location of equipment and their associated infrastructure (foundations, ladders, platforms etc.). Plot plans are developed taking into consideration process, client and safety requirements. Plant coordinates are used extensively in specifying equipment locations. Plot plans are discussed in more detail in Chapter 4.

- Establishing equipment nozzle locations. Nozzles are components of equipment that connect to pipe.

- Routing of pipes. This is a dynamic and iterative process until the equipment and nozzle locations are finalized.

- Designing equipment ancillaries such as foundations, platforms, and stairways.

- Location of safety equipment such as fire hydrants and safety showers.

- Being cognizant of the location of structures, instruments, control valves, electrical raceways and miscellaneous plant items while routing pipe.

The salient skills and qualities required for plant layout and piping design are as follows:

- Sufficient knowledge of the process being used including function of each equipment. This information is obtained from the process group in the form of “Process Flow Diagrams (PFDs)”. PFDs are discussed in detail in Chapter 2.

- Knowledge of the operating and maintenance procedures used for equipment.

- Common sense and attention to detail.

- Ability to think creatively to solve layout problems and challenges.

- Ability to think and visualize spatial relationships between plant items in three dimensions.

- Ability to effectively use computer tools such as 3D modeling software and pipe stress analysis software.

- Excellent communication skills.

- Ability to function effectively as a member of a multi-disciplinary project team.

- Effectively communicate and resolve layout issues and problems with project management.

- Ability to produce, maintain and update project drawings and documents.

- Awareness that conscientious, quality effort during the design and engineering phase can shorten project schedules resulting in economic benefits and client goodwill.

Data used in plant layout and piping design

Massive amounts of data is generated and used in plant layout and piping design. Proper management of plant data is necessary to ensure data accessibility and data integrity, which in turn contributes to the overall quality of the project. Plant data can be classified into three categories.

- Project data consists of information such as plant location, local codes and regulations, access roads, waterways, railways, seismic conditions, climate data (average temperature, wind speed and direction, and rainfall).

- Design and engineering data is internally generated during the design and engineering phases of the project. Examples of such data include equipment sizes, service conditions (temperature, pressure etc.), and mass flow rates.

- Vendor data consists of information provided by equipment vendors by means of vendor drawings and data sheets.

Rules of thumb for plant layout and piping design

The approach to plant layout and piping design can vary depending on the nature of the plant and the project. For example, the design philosophy for an offshore facility is quite different from that for an onshore chemical plant simply because of limited space available on offshore platforms. However, there are a few useful rules of thumb that can be followed.

- Knowledge and understanding of project requirements and project documents.

- Conservation of space and resources.

- Arrangement of equipment in a neat, organized manner taking into account process needs and safety.

- Attention to detail including adjacent equipment, supports and other items, which can cause potential clashes between piping and equipment/supports.

- Consideration of constructability, operability and maintainability of the plant.

- Routing of pipe in a neat, orderly and symmetrical manner keeping in mind the future needs of the plant.

- Avoiding excessive changes in elevations and directions.

- Ensuring consistency in design.

- Avoiding excessive amounts of relocations and revisions by “doing it right the first time”.

Common abbreviations used in plant layout and piping design

- N,S,E,W: North, South, East and West

- CL: Centerline

- El: Elevation

- TOS: Top of Steel

- BOP: Bottom of Pipe

- POS: Point of Support

- BBP: Bottom of Baseplate

- ISBL: Inside Battery Limits

- OSBL: Outside Battery Limits

- AG: Above Ground

- UG: Underground

- ϕ: Diameter

- OD: Outside Diameter of pipe

- ID: Inside Diameter of pipe

- TL: Tangent Line

- TYP: Typical

- PFD: Process Flow Diagram

- P&ID: Piping and Instrumentation Diagram

Abbreviations used in PFDs and P&IDs are explained in Chapters 2 and 5 respectively.

1.2 Procedures and workflow methods used in plant layout and piping design

Front end engineering and design: The complex task of designing and building process plants consists of several phases – design, engineering, procurement and construction. The design phase itself consists of conceptual design, design study and detailed design. The conceptual design phase starts with the Process Flow Diagram (PFD) and client specifications. The project scope is also defined during this phase. The working documents used during this phase are the PFD and the Conceptual Plot Plan. Based on the PFD, a large chemical plant or offshore production facility is sub-divided into several small, manageable areas. A Plot Plan is then generated for each area. Boundary limits for each area are specified using spatial coordinates. The boundaries are known as match lines and play an important role in combining the smaller areas. In offshore platforms, plot plans are generated for each deck of the platform. The outcome of the conceptual design phase is usually preliminary sizes and locations of major equipment, which results in the plot plan for use during the design study phase.

The design study phase plot plan is reviewed and discussed by the client and by the project disciplines. Vessel supports and ancillaries are located during this phase. Preliminary routing of major lines also takes place during this phase. The outcome of the design study phase is a final plot plan and a preliminary Piping & Instrumentation Diagram (P&ID). The P&ID contains details and specifications of all equipment, piping, fittings, instrumentation and control valves. The P&ID also contains references to detailed drawings of equipment. The P&ID serves as the primary reference document in communication between engineering and design personnel in all disciplines. Thus, the P&ID is an important working document in the design and engineering of process plants and piping systems. The final plot plan and the P&ID must be approved by all disciplines including safety and loss control.

The conceptual design and design study phases together constitute the Front End Engineering and Design (FEED) phase of the project. The P&ID, plot plans and elevations are used in building a three dimensional electronic model of the process plant. This 3-D model will contain all the components of the plant including equipment, piping, fittings, control stations and support structures. In recent years, the ability to build 3-D electronic models has been greatly enhanced due to advancements in computer hardware and software.

Detailed design and engineering: The FEED phase is followed by the detailed design and engineering phase where every piece of equipment and every component of piping systems is finalized and specified for procurement. During this phase, piping isometric drawings known as “Issued-For Design (IFD)” drawings are generated for analysis and comment by piping engineers and engineers from other disciplines whose input is required. The IFD drawings are pictorial representations of the piping system and allied components containing all dimensional information. Piping engineers primarily use the IFD drawings for the following purposes:

- Pipe Stress Analysis: The piping systems are analyzed for stress and load to ensure that the pipes are not overstressed (both under installed and operating conditions) and are adequately supported. In many cases, piping systems need to have enough flexibility to allow for thermal expansion. Pipe stress analysis also includes computing loads and stresses on equipment nozzles and ensuring that they are within the allowable limits specified by applicable standards and codes. Pipe stress analysis is performed with the aid of stress analysis software.

- Code compliance: The code that governs the design of piping systems for process plants is ASME B31.3: Process Piping. Piping engineers are responsible for interpreting the code using sound engineering judgment to ensure that the proposed design meets the code requirements.

- Piping material specifications: The piping engineer is responsible for specifying appropriate materials for the pipes. In accomplishing this task, the piping engineer takes into account operating conditions such as the pressure and temperature and also the chemical nature of the fluid being transported. Piping material specification is a very time consuming task but it is very important to specify the right material to ensure the safe and efficient operation of the plant.

The 3-D model is an extremely useful design tool that can be used by all disciplines during the detailed design and engineering phase. The 3-D model is constantly referenced during design review meetings and discussions. These meetings occur frequently and involve all the engineering disciplines and the client. The 3-D model is also useful in clash detection and interference checking. This process saves considerable money and effort by minimizing field rework and field rerouting of pipes. An engineering database is also generated as part of the electronic model. This database is useful in purchasing and procurement functions. As the design is reviewed and updated, so is the 3-D model.

After the detailed design and engineering phase, piping isometric fabrication drawings (also known as spool drawings) along with material specifications are issued for creating the required piping spools. Simultaneously, procurement lists are generated for fittings, instrumentation and other items in the piping system from the engineering database. The procurement lists are used for purchasing the items and contain all the information required to accomplish this task. The procurement lists are also known as “Bill of Materials (BOM)” or “Material Take-off”.

Foundations, structural members and major equipment are put in place using civil/structural drawings, equipment drawings, the 3-D model and other documents. Now the stage is set for the installation of the piping system. Drawings and documents known as “Issued for Construction (IFC)” are used for this purpose. Construction personnel assemble and install the piping system by using IFC drawings and documents.

Figure 1.3 illustrates the workflow methods used in process plant layout and piping design. It should be noted that workflow methods could vary depending on client and company preferences. It should also be noted that the entire process is iterative in nature. There is continuous interaction between the different phases of the project.

Procedures and Workflow Methods Used in Plant Layout and Piping Design

Organizations involved in providing standards and guidelines for plant layout and piping design

Some of the organizations that provide standards and guidelines for plant layout and piping design are listed here along with their web addresses.

- American Society for Mechanical Engineers (ASME): Publishes and updates codes for piping design. The code relevant to the design of piping systems is ASME B31.3 – 2004 Process Piping. (www.asme.org)

- Center for Chemical Process Safety (CCPS): Publishes documents and guidelines related to process safety. The focus is on preventing or mitigating catastrophic releases of chemicals, hydrocarbons, and other hazardous materials. CCPS has published guidelines for “Facility Siting and Layout”. (www.aiche.org/ccps)

- Construction Industry Institute (CII): Provides guidelines for cost effective and safe construction methods and has several publications on constructability. (www.construction-institute.org)

- Society of Piping Engineers and Designers (SPED): Promotes excellence and quality in the practice of piping engineering and design. SPED emphasizes education and training and has certification programs for piping designers. (www.spedweb.org)

- Occupational Safety and Health Administration (OSHA): Provides regulations and safety standards for the operation of process plants. (www.osha.gov)

- National Fire Protection Association (NFPA): Provides fire protection standards for process plants and for gas storage and handling. (www.nfpa.org)

1.3 Physical quantities and units in plant layout and piping design

The physical quantities and units used in plant layout and piping design are summarized in Table 1.1. The units are specified both in the SI System and in the US Customary System (USCS).

| Physical Quantity |

Symbol | SI System | USCS |

|---|---|---|---|

| Length | L | Meter (m) | Feet (ft) |

| Diameter | D | Millimeter (mm) | Inch (in) |

| Thickness | Δx | Millimeter (mm) | Inch (in) |

| Mass | m | Kilogram (kg) | Pound mass (lbm) |

| Time | t | Seconds (s) | Seconds (sec) |

| Temperature | T | Degree Celcius (°C) | Degree Farenheit (°F) |

| Area | A | Square meter (m2) | Square feet (ft2) |

| Volume | V | Cubic meter (m3) | Cubic feet (ft3) |

| Velocity | v | Meters/sec (m/s) | Feet/sec (ft/sec) |

| Acceleration | a | Meters/sec2 (m/s2) | Feet/sec2 (ft/sec2) |

| Force | F | Newton (N) | Pound force (lbf) |

| Pressure | P | Pascal (Pa) | Pounds/in2 (psi) |

| Stress | s | Megapascal (Mpa) | Pounds/in2 (psi) |

| Strain | ɛ | Mm/mm | in/in |

| Work | W | Newton-meter (N.m) | Foot pound force (ft-lbf) |

| Energy | E | Joule (J) | British thermal unit (Btu) |

| Energy flow |  |

kilowatts (kW) | Btu/sec or Btu/hr |

| Enthalpy | H | kilojoules (kJ) | Btu |

| Mass flow |  |

kg/s | Lbm/sec |

| Volume flow |  |

m3/s | ft3/sec |

Notes: The unit of force in the SI system is Newton (N). A Newton is defined as the force required to produce an acceleration of 1 m/s2 on a body of mass 1 kg. The unit of force in the US Customary System (USCS) is Pound force (lbf). One pound force is the force required to accelerate 1 lbm at 32.2 ft/sec2. This leads to the use of a conversion constant, gc in USCS. The following equations are useful in understanding the units of different physical quantities.

Workflow model

1.4 Summary

The objective of process plant layout and piping design activities is to design and construct a plant in a cost-effective manner that will meet the process requirements and client specifications and will operate in a safe, reliable manner. This chapter provides an understanding of the tasks involved and the skills required in these activities. It also provides brief guidelines for plant layout including some general rules of thumb. In addition to adequate and safe design, designers and engineers must consider issues such as constructability, maintainability and operability of a process plant. An overview of the tools, documents, workflow methods and procedures used in plant layout and piping design is also included in this chapter. Organizations that provide guidelines for plant layout and piping design are mentioned in this chapter along with their web addresses. Physical quantities typically used in plant layout and piping design are discussed along with their units both in the SI System and the US Customary System (USCS).

Fundamentals of Process Plant Layout and Piping Design

Practical Exercise 1

1. What are the main tasks of a plant layout designer? (Name just three)

2. Select the correct order of progress during a project.

A. Conceptual Plan, PFD, P&ID, Plot Plan.

B. PFD, Conceptual Plan, Plot Plan, P&ID.

C. PFD, P&ID, Conceptual Plan, Plot Plan.

D. Plot Plan, PFD, Conceptual Plan, P&ID.

3. Besides the design and engineering phases of a project, what other aspects of the project should a good designer be concerned about? Explain.

4. Expand the following abbreviations:

A. IFD:

B. TOS:

C. PFD:

D. ANSI:

5. Psi stands for ______________ and is a unit of _____________ and kPa stands for _____________.

6. The unit of pipe stress in the SI system is _______________.

7. The unit of force in the US customary system is ______________.

8. What are the possible consequences of not knowing maintenance requirements for a particular piece of equipment?

This chapter provides an overview of the processes used in chemical/petrochemical and other facilities. Process Flow Diagrams (PFDs) are also discussed in this chapter.

Learning objectives

- Understanding the processing methods used in the chemical industry.

- Understanding symbols and terminology used in PFDs.

- Interpreting PFDs and be able to use information from PFDs for plant layout and piping design.

2.1 Basic principles of chemical process technology

The chemical process industry primarily comprises processing raw materials such as crude oil and natural gas into finished products such as gasoline (petrol), aviation fuel, cooking gas, fertilizers and polymers to meet the needs of consumers. Chemical processing principles are also used in the production of processed foods and medicines, in water and wastewater treatment, and in pollution control. Thus, the chemical process industry plays a major role in meeting the basic needs of humanity viz., food, shelter, clothing, medicine and transportation. Some products of the chemical industry enter the market as consumer goods while others are intermediates used in the manufacture of consumer items. Considering the great variety of useful products produced by the chemical industry, it touches our lives like no other industry. Chemical and allied industries create and synthesize products and in this sense are different from many manufacturing industries that assemble products. The chemical industry accomplishes the transformation from raw materials to finished products through a series of chemical and physical changes.

Understanding the chemical process technology requires an understanding of the processes that are used in bringing about chemical and physical changes during commercial production. The study of the great number and the vast variety of chemical and physical changes used in the chemical process industry is greatly simplified by organizing the changes into unit operations and unit processes. A comprehensive understanding of technologies used in chemical processing also requires knowledge of the scientific and engineering principles used in the development and use of such technologies.

Unit operations

Chemical processing consists of a sequence of steps some of which may involve only physical changes. Operations that accomplish physical changes in the material being processed are called unit operations. For example, the process used in manufacturing common salt consists of the following sequence of unit operations: transportation of solids and liquids, transfer of heat, evaporation, crystallization, drying and finally screening. Unit operations are identical in fundamental principles regardless of the material being processed. By systematically studying these operations, which clearly cross industry and process lines, the treatment of all processes can be unified and simplified. Physical and mathematical models developed for each unit operation can be applied across a broad spectrum of chemical industry. Some important unit operations, their application and equipment used are described here.

Distillation: Distillation is the process of separation of components by using the differences in their boiling points. The more volatile component (with a lower boiling point) vaporizes first and is condensed. Distillation is widely used in the chemical process industry. A very important application is the atmospheric distillation of crude oil used in the petroleum industry to derive products such as gasoline and kerosene. The equipment used in this process is a distillation column. The distillation column typically consists of trays through which the vapor bubbles up and the liquid flows down. It is equipped with a condenser on top and a reboiler at the bottom. In some cases, packing material is used instead of trays. The diameter of the column depends on the quantity of material being processed. The numbers of trays or stages dictate the height of the column. The number of stages is a function of the components in the mixture being separated and the vapor-liquid equilibrium characteristics. Condensers and reboilers are heat exchangers that are designed by using the principles of heat transfer.

Drying of solids: The unit operation here is the removal of moisture. Typical equipment used in drying are spray driers, rotary driers and tunnel driers. Each of these is described below with examples of applications in the chemical process industry.

- The spray drier is suitable for large capacity operation of liquid feed to give powdered, spherical, free flowing product. Spray driers are used in production of pigments, detergents, synthetic resins and inorganic salts.

- The rotary drier is suitable for drying free flowing granular solids that do not stick. High temperature rotary kilns are used in the manufacture of cement.

- The tunnel drier is used in drying pastes or powders in trays. It is also used in drying pottery, lumber and leather in sheet or shaped forms.

Evaporation: Evaporation is used in increasing the concentration of a solution by vaporizing a portion of the volatile solvent; usually water. The feed is a dilute solution and the product is a concentrated solution. Evaporation is used in the production of sugar and common salt. It is used in thickening the liquor in paper mills and also in producing potable water from seawater. Evaporators consist of vessels with a bank of tubes. The material to be concentrated flows inside the tubes and the heat required is generated by steam condensing on the outside of the tubes. The design of evaporators involves the principles of heat transfer and mass and energy balances. In a single-effect evaporator, the vapor from the boiling liquid is condensed and discarded. In a multiple-effect evaporator, the vapor from the first evaporator is fed into the steam chest of the second evaporator; the vapor from the second evaporator is fed into the steam chest of the third evaporator and so on. Multiple-effect evaporators decrease the consumption of steam required.

Gas absorption: In gas absorption, a liquid solvent absorbs one of the components in a mixture of gases. An example of gas absorption is absorption of ammonia from a mixture of ammonia and air using water as the solvent. This technique is also used in the removal of hydrogen sulfide from hydrocarbons. A common apparatus used in gas absorption is the packed tower. The device consists of a cylindrical tower, equipped with a gas inlet and distributing space at the bottom and a liquid inlet with a distributor at the top. The outlets for the liquid with the solute gas and the lean gas are located at the bottom and top respectively, thus achieving a counter flow of the liquid and gas streams. A mass of inert solid shapes forms the core of the tower between the inlet and outlet streams. This packing promotes intimate contact between the liquid and gas phases. The design of the absorption tower uses the principles of diffusion and mass transfer. The reverse process of gas absorption is known as desorption or gas stripping. In this case the solute is removed from the liquid solvent by contacting it with an inert gas. The pure solvent is then recycled and reused for gas absorption.

Liquid-liquid extraction: In this unit operation, one constituent from a liquid mixture is removed by using a liquid solvent. The liquid phase containing the solute and the solvent is known as the ‘extract’ whereas the liquid phase with the solute removed is known as the “raffinate”. As an example, naphthenes are removed from lube oil fractions using furfural as a solvent. Typical equipment used in liquid-liquid extraction includes a battery of mixers and settlers, packed columns and towers with mechanisms for agitation of the liquid phase to promote intimate contact.

Leaching: In leaching, a solvent is used in removing a soluble component from a mixture in the solid phase. This technique is widely used in the mining industry to recover valuable metal from ores. A common set-up used in leaching is percolation of solvent through a stationary bed of solid to be leached. Other techniques such as moving-bed leaching and dispersed-solid leaching are also available for use.

Crystallization: Crystallization is the formation of solid particles from a homogenous phase. Since a variety of materials are marketed in crystalline form, crystallization from solution is an important chemical processing technique. Crystallization is a very useful method for producing pure chemical substances in a satisfactory condition for packing and storing. It needs to be noted that pure crystals can be formed even from an impure solution. The process of crystallization is used in the production of common salt, sugar, dyes and pigments. Crystallization equipment can be classified into the following three categories:

- Tank crystallization – Here, super-saturation is achieved by cooling hot, saturated solutions. The cooling is achieved by natural convection and can be enhanced by cooling coils or cooling jackets.

- Evaporator-Crystallizers – Here, super-saturation is achieved by evaporation.

- Adiabatic Vacuum Crystallizers – Here, super-saturation is achieved by evaporation combined with adiabatic cooling, which causes nucleation and growth of crystals.

Other unit operations

- Filtration is used in separating solids from solutions. Examples of this operation are separation of minerals from slurries and pulp fibers from thick liquor in paper mills. Typical equipment used in filtration are rotary drum filters and filter press.

- Removal of particulate solids from gases is used in controlling air pollution and in cutting down product losses. Typical equipment used in achieving these are cyclone separators, electrostatic precipitators wet scrubbers.

- Centrifugation is used in separating very finely divided solids from liquid or liquids from liquid emulsions. This is achieved by the use of rotating centrifuges.

- Membrane Separation uses a semi-permeable membrane to achieve separation. This technique is used in dialysis where caustic is separated from sugar or cellulose due to the wide difference in molecular weights. Micro-porous Ni barriers are used in separating light uranium compounds from heavy uranium compounds, since the light compounds diffuse through the membrane or barrier.

Unit processes

Just as unit operations are useful in the systematic study of physical changes, the concepts of unit processes can be used in systematizing chemical changes or reactions found in chemical industries. The advantage is that prior performance data from a group of chemical reactions can be applied to the production of other chemicals using similar unit processes. As an example, nitration is a commonly used unit process. The nitration reaction is an exothermic reaction and has certain characteristics of reaction rates and reaction equilibrium. This data has led to the design for nitration reactors. These reactors are typically liquid phase reactors made of cast iron with provision for mixing of reactants and for heat removal. Similar designs can be used for other nitration reactors. Listing all unit processes used in the chemical industry is beyond the scope of this course manual. A few commonly occurring unit processes and their applications are described in the following paragraphs.

Alkylation: Alkylation is a unit process where an alkyl radical (-CH3) is added to a reactant. An example is alkylation of butylene in the presence of heat and catalyst to produce iso-octane, which is an important additive for gasoline.

Combustion: Combustion is burning of fuel where the fuel reacts with oxygen to form combustion products. More importantly, the heat released during combustion is used in process heating and in power generation.

Condensation: Condensation is a chemical reaction where water is one of the products. Condensation reactions are widely used in the manufacture of organic chemicals, dyestuffs and synthetic perfumes.

Cracking or Pyrolysis: Cracking is a unit process where high molecular weight compounds are broken down into useful products having lower molecular weights. Cracking is used in petroleum refining where the heavier fractions of crude distillation are broken down into more useful products. This reaction takes place in a fluid bed consisting of a catalyst. The reactors are known Fluid Catalytic Cracking Units (FCCU).

Esterification: Esterification is the reaction of an organic acid with alcohol to produce esters or organic salts. This reaction is used in manufacture of soaps and oils.

Halogenation: Halogenation is addition of chlorine molecule and is used in the production of organic chemicals.

Isomerization: Isomerization is used in changing the structural formula of organic compounds from straight chain to branched structure and is used in petroleum refining.

Polymerization: Polymerization reactions are used in building large polymer macromolecules. There are two types of polymerization reactions – addition polymerization and condensation polymerization. Polymerization reactions are used in the manufacture of plastics and synthetic fibers.

Engineering and scientific principles used in chemical process technology

Chemistry: The principles of chemistry are essential for understanding the basis of chemical reactions involved in chemical processing. Balanced chemical equations are important in calculating the yield of products.

Mass and energy balances: The principles of mass and energy balances are used in sizing of equipment for processes and also in determining energy requirements (heat addition or removal) for processes. Mass and energy balance calculations are used in monitoring the flow of material and energy through different units in any chemical plant. This involves the synthesis and analysis of Process Flow Diagrams (PFDs).

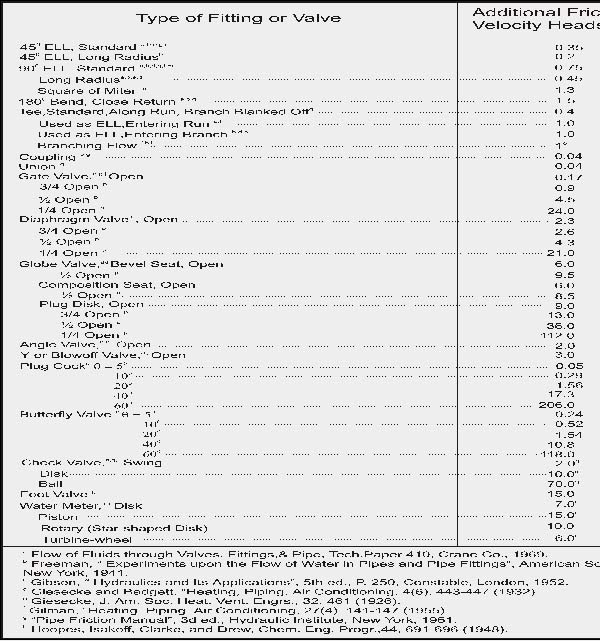

Fluid mechanics: In chemical processing, fluids must be transported between process units and different equipment. Fluids are typically transported in pipes. The principles of fluid mechanics are used in the design of piping systems in chemical process industries. Piping systems include pipes, fittings, valves, pumps and ancillary equipment. Important considerations in the design of piping systems are fluid properties (density, viscosity), fluid velocity and pressure and elevation differences. Principles of fluid mechanics are also used in measurement of pressure and flow rates of fluids. Pumps are used in providing the required energy for fluid transport. The most commonly used pump is a centrifugal pump.

Heat transfer: Addition or dissipation of heat is a common feature in the chemical industry. The principles of heat transfer are used in the design of heat exchangers, heating coils, furnaces, fired heaters, condensers, reboilers and jacketed vessels.

Thermodynamics: The concepts of thermodynamics have important applications in chemical processing. It is particularly useful in calculating the following quantities related to chemical reaction: heat of reaction – whether heat is absorbed (endothermic) or released (exothermic), equilibrium constant and how it is affected by changes in temperature and pressure, equilibrium conversion of a reactant. The principles of thermodynamics are also used in energy balances, in calculating heats of solution and absorption, in calculating heat effects in phase changes and in calculating efficiencies of energy producing and energy consuming devices.

Reaction kinetics: The principles of reaction kinetics are used in the design of chemical reactors and in the prediction of reaction rates, reaction conversions and the time required to achieve a particular level of conversion. Chemical reactors are classified as homogeneous (single phase) and heterogeneous (multiple) and further into batch reactors, stirred tank reactors and tubular reactors.

Process engineering economics: Process engineering economics is concerned with the economic aspects of the chemical process industry. Process engineering economics is used in estimation of capital costs, operating costs and other cost factors. It is also used in the calculation of rate of return for capital projects. The concepts of process engineering economics are used in evaluating alternatives and in selecting alternatives that minimize costs and maximize profits at the lowest capital expenditure. Any comprehensive evaluation of chemical process technology must include economic study and analysis.

Mass transfer: The principles of mass transfer and diffusion are used in the design of equipment such as distillation columns, absorption towers, dryers and ion-exchange units.

Process control and instrumentation: Appropriate instrumentation and communication methods are necessary to monitor the status of a given process. Proper control strategies and methods are essential in maintaining process variable within reasonable limits and also in ensuring process safety. An important tool in the synthesis of instrumentation and control strategies is the Process & Instrumentation Diagram (P&ID).

2.2 Process flow diagrams (PFDs)

Process flow diagrams (PFDs) are schematic representations of process plants that provide an overview of all the processing steps (unit operations and unit processes) used in process plants.

PFDs include the following information:

- All major equipment used in the plant. Equipment can be classified as Process Equipment (Reactors, Towers, Exchangers) and Mechanical Equipment (Pumps, Compressors, Blowers).

- Stream information and flow directions. Streams within a process plant can be classified into Material Streams and Energy Streams. Material streams show the flow of reactants, products and other fluids in the plant while energy streams show the flow of heat energy.

- Mass flow rates, compositions, temperature, and phase fraction (liquid or vapor) of each material stream.

- Energy (heat) transfer rates.

- Sometimes, the preceding information is presented in the form a “Stream Summary Table” instead of indicating it on the PFD.

Icons used in process flow diagrams

Figure 2.1 shows the icons commonly used in PFDs.

Icons Commonly Used in Process Flow Diagrams (From: Product & Process Design Principles, Warren Seider et al., 2nd ed., John Wiley and Sons, 2004)

Process flow diagram for the manufacture of vinyl chloride

Figure 2.2 shows the PFD for the manufacture of vinyl chloride using chlorine and ethylene as raw materials. Vinyl chloride is an important product since it is used in the manufacture of polyvinyl chloride (PVC). This manufacturing process involves three major steps.

- Direct chlorination of ethylene to produce ethylene dichloride (1, 2-dichloroethane).

- Pyrolysis of ethylene dichloride to produce vinyl chloride and hydrogen chloride.

- Separation and purification steps to separate vinyl chloride from hydrogen chloride and unreacted components.

Process Flow Diagram for the Manufacture of Vinyl Chloride (From: Product & Process Design Principles, Warren Seider et al., 2nd ed., John Wiley and Sons, 2004)

Table 2.1 gives typical information on different streams in the PFD for the manufacture of vinyl chloride.

| Stream Number | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Temperature (°C) |

25 | 25 | 90 | 90 |

| Pressure (Atm) |

1.5 | 1.5 | 1.5 | 1.5 |

| Vapor Fraction | 1.0 | 1.0 | 0.0 | 0.0 |

| Mass Flow (kg/hr) |

20 410 | 51 545 | 71 955 | 1 19 910 |

| Component Mole Fractions Ethylene Chlorine Ethylene dichloride Vinyl chloride Hydrogen Chloride |

1 0 0 0 0 |

0 1 0 0 0 |

0 0 1 0 0 |

0 0 1 0 0 |

| Stream Number | 5 | 6 | 7 | 8 |

|---|---|---|---|---|

| Temperature (°C) |

91.3 | 242 | 500 | 170 |

| Pressure (Atm) |

26 | 26 | 26 | 26 |

| Vapor Fraction | 0.0 | 1.0 | 1.0 | 1.0 |

| Mass Flow (lbm/hr) |

1 19 910 | 1 19 910 | 1 19 910 | 1 19 910 |

| Component Mole Fractions Ethylene Chlorine Ethylene dichloride Vinyl chloride Hydrogen Chloride |

0 0 1 0 0 |

0 0 1 0 0 |

0 0 0.25 0.375 0.375 |

0 0 0.25 0.375 0.375 |

| Stream Number | 9 | 10 | 11 | 12 |

|---|---|---|---|---|

| Temperature (°C) |

6 | 6.5 | -26.4 | 94.6 |

| Pressure (Atm) |

26 | 12 | 12 | 12 |

| Vapor Fraction | 0.0 | 0.0 | 1.0 | 0.0 |

| Mass Flow (lbm/hr) |

1 19 910 | 1 19 910 | 26 500 | 93 410 |

| Component Mole Fractions Ethylene Chlorine Ethylene dichloride Vinyl chloride Hydrogen Chloride |

0 0 0.25 0.375 0.375 |

0 0 0.25 0.375 0.375 |

0 0 0 0 1 |

0 0 0.4 0.6 0 |

| Stream Number | 13 | 14 | 15 | 16 |

|---|---|---|---|---|

| Temperature (°C) |

57.7 | 32.2 | 145.6 | 90 |

| Pressure (Atm) |

4.8 | 4.8 | 4.8 | 4.8 |

| Vapor Fraction | 0.23 | 0 | 0.0 | 0.0 |

| Mass Flow (lbm/hr) |

93 410 | 45 455 | 47 955 | 47 955 |

| Component Mole Fractions Ethylene Chlorine Ethylene dichloride Vinyl chloride Hydrogen Chloride |

0 0 0.4 0.6 0 |

0 0 0 1.0 0 |

0 0 1.0 0 0 |

0 0 1.0 0 0 |

Process utilities: All process plants require utilities such as steam and cooling water. The primary purpose of utilities is heating and cooling of process streams. Heating is accomplished by using steam. Cooling is accomplished by using cooling water and refrigerants. Table 2.2 lists the pressure and temperature ranges for utilities used in process heating. The utilities are listed in the order of increasing cost per kJ of heating. Table 2.3 lists utilities used in process cooling in the order of increasing cost per kJ of cooling.

| Utility | Pressure Range (kPa) | Temperature Range (°C) |

|---|---|---|

| Low Pressure Steam (LPS) | 200 to 300 | 120 to 140 |

| Medium Pressure Steam (MPS) | 700 to 1400 | 160 to 190 |

| High Pressure Steam (HPS) | 2700 to 4200 | 230 to 260 |

| Petroleum Oils (PO) | Below 320 | |

| Dowtherm (DT) | Below 400 |

| Utility | Description |

| Air Cooling (AC) | Supply at 30°C, ΔT = 5°C to 10°C |

| Cooling Water (CW) | Supply at 25°C, ΔT = 10°C to 15°C |

| Chilled Water (CHW) | ΔT = 25°C to 50°C |

| Refrigerated Brine (RB) | Cooling in the range of 10°C to –18°C |

| Propane Refrigerant (PR) | Cooling in the range of -6°C to –40°C |

Equipment: Different types of process and mechanical equipment are used in process plants. They include vessels, towers, heat exchangers, fired heaters, pumps and compressors. Proper specification of equipment is an important task in process plant layout and design. Specifications required for each type of equipment are summarized in Table 2.4.

| Equipment | Specifications Required |

| Vessels | Pressure, Temperature, Height, Diameter, Materials of Construction, Orientation. |

| Towers | Pressure, Temperature, Height, Diameter, Materials of Construction, Orientation, Number and type of trays, Height and Type of Packing. |

| Fired Heaters | Type, Duty, Tube Pressure and Temperature, Materials of Construction, Radiant and Convective Heat Transfer Areas. |

| Heat Exchangers | Type, Duty, Number of Shell and Tube Passes, Operating Pressure, Temperature, and Pressure Drop for both Shell and Tubes, Materials of Construction. |

| Pumps | Flow Rate, Suction and Discharge Pressures, Temperature, Shaft Power, Type of Driver, Materials of Construction. |

| Compressors | Inlet Flow Rate, Suction and Discharge Pressures, Temperature, Shaft Power, Type of Driver, Materials of Construction. |

2.3 Summary

In this chapter, the basic principles of chemical technology have been discussed. Unit Operations and Unit Processes typically used in process plants have been described. Process Flow Diagrams (PFDs) and the information presented in PFDs have been discussed at length.

Fundamentals of Process Plant Layout and Piping Design

Practical Exercise 2

Given the attached PFD and the process description for the production of vinyl chloride:

1. Identify unit operations and unit processes.

2. Specify the temperature and the pressure of some of the streams

Process Description For The Manufacture of Vinyl Chloride (VC) By Thermal Pyrolysis of Ethylene Dichloride (EDC)

EDC vapor at a pressure of 4 atm. is dried by using a silica gel drier. It is then sent to a stainless steel tubular cracking furnace where the conditions are maintained at about 480-520°C and 4 atm. The furnace is heated by external flue gas. The contact surface catalyst within the tubes is pumice or charcoal. The conversion per pass is around 50% and the ultimate yield is about 95%. The product from the furnace is quenched with cold EDC to prevent the back reaction and to form condensable product components. Uncondensed gases are sent to a surface heat exchanger to condense any remaining EDC and VC present in vapor form. The non-condensable HCl is sent to an adjacent process area for further processing. The condensate is then sent to a VC still or fractionator where VC is taken as an overhead product and sent to storage after stabilization. The bottoms from the VC fractionator is to an EDC still to further separate EDC from heavier fractions. Part of the separated EDC is recycled in vapor form and the rest, in liquid form, is used for cold quench.

In this chapter, equipment typically used in process plants is described. This includes process equipment such as reactors, towers and exchangers and mechanical equipment such as pumps and compressors. Process and mechanical equipment used in process plants are discussed in this chapter.

Learning objectives

- Process equipment: reactors, towers, exchangers and vessels.

- Mechanical equipment: pumps and compressors.

- Equipment nozzle specifications.

- Equipment drawings.

- Equipment foundations and supports.

3.1 Introduction

Equipment in process plants can be classified into two categories – process equipment and mechanical equipment. Process equipment is used in the different processing steps as indicated by the Process Flow Diagram (PFD). Reactors and heat exchangers are examples of process equipment. Mechanical equipment is used in the transport of fluids from one process unit to another and also in the compression of gases. Pumps and compressors are examples of mechanical equipment. Mechanical equipment consists of rotating machinery. Good practices in process plant layout and piping design requires adequate knowledge of equipment used in process plants and the ability to interpret equipment documents and drawings. Both these types of equipment are discussed in this chapter.

3.2 Process equipment

Towers

Towers are tall, slender pieces of vertical equipment found in process plants. The most important example of a tower is the distillation column, also known as a fractionating tower. The distillation column is used in the separation of components based on the differences in the boiling points of the components. For example, in the distillation of crude oil, preheated feed is fed to a “flash zone” in the column where liquid and vapor separate. The lighter fractions boil first and rise to the top of the column and the heavier fractions remain as liquid and settle at the bottom of the column. Figure 3.1a shows a PFD for a typical distillation column.

Process Flow Diagram (PFD) for a Typical Distillation Column. (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

Layout and design considerations for towers

The following factors are considered in the design and layout of distillation columns:

- Column height: The column height is a function of the number of stages. The number of stages required depends on components being separated and their vapor-liquid equilibrium characteristics.

- Column diameter: The column diameter is a function of the mass flow rate of the mixture being separated.

- Space for ancillary equipment: A distillation column has associated with it ancillary equipment such as an overhead condenser, a reboiler at the bottom, a reflux drum and reflux and bottom pumps. The location and space occupied by the ancillary equipment must be considered during the design and layout of distillation columns.

- Maintenance access: Space must be provided for the use of davits and trolley beams and equipment used in the removal internal and external items of the tower.

- Tower elevation: The tower elevation is the distance from the grade to the Bottom Tangent Line (BTL) of the vessel. Factors used in determining tower elevation are – Net Positive Suction Head (NPSH) required for the bottoms pump, operator access, tower dimensions, type of heads, tower support (skirt), diameter of bottoms pipe and tower foundation.

- Tower internals: These are devices used in promoting contact between vapor and liquid phases and in ensuring even distribution of the liquid phase. Commonly used internal devices are trays and packing. In tray towers, the normal spacing between trays is two feet. Tray towers require the use of down comers which are channels that promote the flow of liquid from the top to bottom trays. Packed towers consist of a liquid distributor at the top, the packing material and packing support. Raschig rings and slotted rings are examples of packing materials.

Figure 3.1b shows a typical plan arrangement for a distillation column and Figure 3.1c shows the elevation view of a distillation column and its ancillary equipment.

Plan Arrangement for a Distillation Column (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

Elevation View of a Distillation Column and Ancillary Equipment (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

A “Process Vessel Sketch” for a typical distillation column. The process vessel sketch gives the major dimensions of the column including the diameter and tangent-to-tangent height.

Process Vessel Sketch for a Distillation Column (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

An important consideration in piping layout and design is the location of equipment nozzles. Equipment nozzles provide the connection between equipment and piping. In addition, nozzles are used for instrumentation such as temperature and pressure sensors. Large diameter nozzles are used in providing maintenance access. The process vessel sketch also includes information on the location of nozzles. The nozzles are described in a nozzle summary table, which is shown in Table 3.1. The process vessel sketch and the nozzle summary table provide information for vessel fabrication.

| Symbol | Size and Rating | Service |

|---|---|---|

| A | 18” 150# RF | Vapor |

| B | 3” 150# RF | Reflux |

| C | 6” 150# RF | Feed |

| D | 10” 150# RF | Reboiler Draw Off |

| E | 10” 150# RF | Reboiler Return |

| F | 6” 150# RF | Botoms Outlet |

| Patient | 1” 150# RF | Pressure |

| T | 1” 150# RF | Temperature |

| L | 2” 150# RF | Level |

| S | 1” 150# RF | Steam Out |

| M | 24” 150# RF | Maintenance Access |

| G | 3” 150# RF | Drain |

Platforms and ladders:

Tall towers are equipped with platforms and ladders to provide access for operation and maintenance. Platforms are attached to the tower using brackets. Circular platforms are commonly used. Usually, platforms have minimum width of about 3 ft beyond the projection of controls and instruments. The minimum headroom above a platform is about 7 ft. Ladders are used in accessing platforms and the maximum ladder run is 30 ft. Figure 3.3 shows nozzle and platform elevations for a typical distillation column.

Nozzle and Platform Elevations for a Distillation Column (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

Tower piping: The piping associated with the tower is routed in areas away from ladders and platforms. Adequate spacing is provided between adjacent piping and the insulation thickness is taken into account in determining this spacing. Sufficient room for expansion must be provided for high temperature piping.

Reactors

Reactors are process units used in accomplishing unit processes. Unit processes are chemical reactions necessary to transform raw materials to finished products and were discussed in Chapter 2. Reactors are usually vertical, hollow steel vessels operating at high temperatures and pressures.

Layout and design considerations for reactors

The following factors must be considered in the layout and design of reactors:

- Facility for loading and removal of catalysts, mostly in the form of pellets. Very often, reactions take place in the presence of a ‘catalyst’ material that promotes the reaction but does not take part in the chemical reaction. Examples of catalysts are alumina, zinc oxide and platinum.

- Requirement of space for loading/unloading of catalyst.

- Flexibility of connecting lines to accommodate line expansion due to high temperature during operation and contraction during shut down.

- Location of sampling ports to sample catalyst pellets. It is necessary to sample and test the catalyst for its effectiveness. The catalyst needs to be regenerated periodically after it is “spent”.

- Location and sizes of nozzles for catalyst unloading and loading.

The following factors are considered in determining the elevation of the Bottom Tangent Line (BTL) of a reactor: reactor dimensions, type of heads, type of support and catalyst unloading method. The piping layout for a reactor should minimize piping runs of expensive alloy piping and should also provide sufficient flexibility for high temperature piping.

Figure 3.4 shows the details for a typical reactor.

Typical Reactor Details (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

The important nozzles for a reactor are nozzles for raw material inlet and catalyst loading on the top head and nozzles for product outlet and catalyst unloading on the bottom head. In addition, there are several nozzles for temperature probes and sampling probes. The layout should leave sufficient room for the withdrawal of the probes. Figure 3.5 is a process vessel sketch for a reactor showing the location of the important nozzles.

Process Vessel Sketch for a Reactor (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

The different types of supports for a reactor are skirt support, lug support and ring girder support and are shown in Figure 3.6.

Methods for supporting a Reactor (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

Heat exchangers

Heat Exchangers are used in heating, cooling, vaporizing, and condensing process fluids by exchanging heat from other fluids or outside sources.

Types of heat exchangers: The five major types of heat exchangers are Shell and Tube, Double Pipe, Plate and Frame, Spiral, and Air-cooled and they are illustrated in Figure 3.7.

Types of Heat Exchangers (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

Heat exchanger applications:

Typical applications of heat exchangers are described here.

- Coolers: A process fluid is cooled using a cooling medium such as cooling water, refrigerant, air or dowtherm.

- Heaters: A process fluid is heated using heating media such as hot water, hot oil or condensing steam.

- Chiller: A process stream is cooled to very low temperature by using a refrigerant. The refrigerant absorbs heat from the process stream and evaporates.

- Condensers: Process vapors are condensed to liquid state by using cooling water, air or other medium.

- Reboilers: Used in distillation systems to boil/vaporize the bottoms liquid using steam/hot oil as the heating medium.

- Heat/Energy conservation: Hot, effluent streams are used in pre-heating feed streams before discharge. This saves energy and also reduces environmental problems.

A description of the five major types of exchangers is provided in the following section.

1. Shell and Tube Heat Exchanger (STHE): A typical STHE consists of a cylindrical shell containing a bundle of tubes. The shell side fluid passes over the tubes and the tube side fluid passes through the tubes causing exchange of heat between the tube fluids. The following points should be noted about the STHE:

- Nozzles are provided for the shell side and tube side fluids.

- Horizontal baffles are provided to create multiple passes on the tube side.

- Vertical baffles in the shell side to ensure a flow pattern that provides good contact between shell and tube side fluids.

- Tubes are supported in a frame called tube sheet.

- For horizontal installations, the exchanger is supported by saddles and by lugs for vertical installations.

- Layout for STHE: The most important factor is to provide enough space for the removal of tube bundles and for the removal of shell bonnet.

Figure 3.8 illustrates typical components of a Shell and Tube Heat Exchanger.

Shell and tube heat exchanger with floating head (courtesy of the Tubular Exchanger Manufacturers Association)

2. Plate and frame exchangers: They are generally used in low temperature, low pressure applications. The advantage they offer is economy of space. Sufficient space must be provided for plate removal and for controls.

3. Spiral heat exchangers: They have the advantages of economy of space and compact layout. Sufficient space must be provided for opening of swing cover plates and for controls.

4. Double pipe heat exchangers: They are also known as Fin Tube Heat Exchangers. They consist of two concentric pipes. One of the fluids flows in the inner tube and the other fluid flows in the annular region between the two tubes. The inner tube may be finned to increase heat transfer surface area. The disadvantage is the large amount of space occupied.

5. Air-Cooled Heat Exchangers: In this type of exchanger, circulating air is the cooling medium. It consists of a bank of tubes carrying the hot fluid, which is cooled by flow of air across the tube bank. Air fans and their drives occupy most of the space. Air-cooled exchangers are usually mounted on top of the pipe racks.

Layout and piping design for heat exchangers:

Heat Exchangers are located close to the process equipment they service. For example, a reboiler is located close to the distillation tower it services. Some of the factors to be considered in the layout and piping design for heat exchangers include:

- Adequate space must be provided for the removal of channel heads, tube bundles and shell covers.

- Piping runs should be minimized for expensive, high temperature, alloy piping.

- High temperature lines should be routed so as to provide sufficient flexibility for thermal expansion.

- Sufficient space must be provided for operator and maintenance access.

Figure 3.9 illustrates typical layout for heat exchangers

Typical Layout for Heat Exchangers (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

Vessels and other process equipment

Vessels can be grouped into horizontal vessels and vertical vessels. Horizontal vessels are also known as drums or accumulators. They are used in the storage of process liquids. Process liquids are received and collected in these vessels. Drums consist of nozzle connections for inlet and outlet and man-ways for maintenance access. They also consist of level gauges, indicators and alarms. Distillation columns and reactors, which were discussed earlier, are examples of vertical equipment. Another example of vertical equipment is a “Gas Absorption Tower”. The gas absorption tower is a vertical column consisting of packing material, which provides the contact surface between the gas and the liquid. Liquid solvent is distributed from the top and the gas mixture is blown from the bottom. The liquid solvent absorbs the soluble portion of the gas mixture. For example, ammonia is absorbed from a mixture of ammonia and air using water as the solvent.

3.3 Mechanical equipment

Mechanical equipment is used in the transport of fluids and also in the compression of gases. Pumps are used in the transport of fluids and compressors are used in gas compression.

Pumps

Pumps are mechanical equipment used in the transport of fluids. Pumps add mechanical energy or “head” to the fluid being transported. The criteria used in the selection of pumps are as follows:

- Characteristics and properties of the fluid being pumped including density, viscosity, vapor pressure and chemical composition.

- The capacity or the volume flow rate (gpm or m3/s) of the fluid to be pumped.

- The head to be supplied by the pump. This is usually expressed in terms of feet (or meters) of the fluid being pumped.

- Pressure, temperature of the fluid being pumped.

- Space constraints.

- Cost factors – capital and operating costs.

- Maintenance requirements and reliability.

Classification of pumps

The three major types of pumps are – centrifugal pumps, reciprocating pumps and rotary pumps.

Centrifugal pumps:

Centrifugal pumps are the most commonly used pumps. They are very versatile pumps and can handle a broad range of flow rates and pressures. They operate at constant speeds. They can be configured either horizontally or vertically and in single or multiple stages. Figure 3.10 illustrates the typical components of a centrifugal pump, which consists of an impeller, a casing, and suction and discharge nozzles. Associated with the pump are the motor drive and the base plate.

Typical Components of a Centrifugal Pump (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

Reciprocating pumps:

Reciprocating pumps consist of a piston-cylinder mechanism. They are typically used in injecting precise amount of fluids and in handling lower flow rates. Reciprocating pumps are also known as “Positive Displacement Pumps”.

Rotary pumps:

Rotary pumps use gears, screws and cams to move the fluid. They are useful in pumping viscous fluids and in achieving a constant and smooth discharge.

Terminology associated with pumps

- Net Positive Suction Head (NPSH): The NPSH required (NPSHR) is a measure of the pressure drop from the inlet nozzle to the eye of the impeller. The pump manufacturer specifies the NPSHR usually in feet of water. The NPSH available (NPSHA) must be greater than NPSHR. NPSHA is determined by the layout of the source vessel and the pump.

- Allowable Nozzle Loads: Stresses are induced in the suction and discharge nozzles of the pump because of the forces and displacements of the connecting pipe. These stresses should be within limits specified by the vendor and by the codes. The limits specified are called as allowable loads.

- Vapor Pressure and Cavitation: The vapor pressure of the fluid being pumped is the saturation pressure at the operating temperature of the pump. This can be obtained from thermodynamic tables and charts. If the pressure in the pump suction drops below the vapor pressure, the liquid will flash forming some vapor. The liquid–vapor mixture leads to the formation of vapor bubbles, which collapse upon impact on the surfaces of the impeller and the casing. This results in the erosion and damage of the impeller and casing surfaces. Cavitation also causes noise, loss of head and capacity.

Layout and design considerations for pumps and pump piping

- Pump piping must be adequately supported so as to avoid excessive loads on pump nozzles.

- Pump piping must be routed such that existing support structures can be used.

- The length of the suction piping must be minimized to avoid excessive pressure drops.

- Pump piping is routed so as to satisfy line flexibility requirements to allow room for line expansion and contraction (thermal effects).

- Pumps are located so as to optimize the use of existing structural steel for providing adequate support for pump piping. It is for this reason that pumps are located adjacent to pipe racks. Pumps can also be located directly under the process equipment serviced by the pump.

Figure 3.11 is a plan view of typical pump locations and Figure 3.12 is an elevation view of typical pump locations.

Plan View of Typical Pump Locations (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

Elevation View of Typical Pump Locations (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

Configuration of pump piping

Pump piping consists of valves, strainers and pressure indicators. Figure 3.13 shows typical components of piping systems on the suction side as well as the discharge side. The suction side piping system consists of the suction line, a shut-off valve, a strainer to trap particles and an eccentric reducer. The discharge piping consists of a concentric reducer, a pressure indicator to monitor the discharge pressure of the pump, a check valve to prevent back flow, a gate valve and the discharge line.

Typical Components of Suction and Discharge Piping (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall)

3.4 Summary

Process and mechanical equipment typically found in process plants have been discussed in this chapter. The different types of equipment, their typical applications and the factors to be considered in the design and layout of such equipment have been explained. The equipment considered in this chapter includes towers, reactors, heat exchangers and pumps. The nozzle specifications and supports for equipment have also been briefly discussed.

Fundamentals of Process Plant Layout and Piping Design

Practical Exercise 3 (Towers and Reactors)

1. What are the two most important dimensions for a tower?

2. What does NPSH stand for?

3. Mention three important factors used in determining tower elevation.

4. What are the two different types of internals used in towers?

5. What is the purpose of reactors?

6. Name three types of supports typically used for supporting reactors.

This chapter discusses the basic principles used in plant layout. Plant layout specifications and guidelines are described. The starting point for the design of process plants and piping system is the generation of “Plot Plans” and equipment arrangement drawings. Examples of plot plans and equipment arrangement drawings are provided in this chapter.

Learning objectives

- Plant layout specifications.

- Guidelines and codes for plant layout.

- Safety considerations.

- Plot plans.

- Equipment arrangement drawings.

4.1 Plant layout specifications

Plant layout specifications provide guidelines and requirements for arrangement of equipment and structures within a plant. These guidelines take into account compliance with national and local codes and regulations. Additional factors to be considered are:

- Plant safety

- Plant operability

- Plant maintenance

- Site conditions – soil, seismic data etc.

- Environment

- Atmospheric conditions – prevailing winds, average ambient temperature

The following terminology is frequently used in plant layout and plot plans:

- Operator Access: This is the space required between units for operator functions such as walking, climbing, operating valves, viewing instruments and for safe exit in case of an emergency.

- Maintenance access: This is the space required for servicing of process equipment and for removal and restoration of components of equipment.

Some examples of plant layout specifications are listed here.

- Provision of adequate service roads and access paths for maintenance and emergency response. Recommended road widths are 24 ft for main roads, 16 ft for secondary roads and 10 ft for access paths.

- Minimum safety distances between hazardous equipment (at high temperature, high pressure) and inhabited spaces such as control rooms and administrative buildings.

- Minimum recommended distances between process units such as furnaces and reactors and other equipment.

- Equipment elevations allowing adequate room for supports, operation and maintenance. Usually grade or datum is fixed at 100 ft.

- Tall equipment adequately equipped with platforms and ladders to provide operator and maintenance access.

- A minimum head room of 7 ft above platforms and platform width should be a minimum of 3ft plus any equipment/instrument projections.

- Access to platforms is by means of ladders. Maximum vertical run for ladders is 30 ft and minimum width is 1’ – 6”.

4.2 Plot plans

Plot plans are plan view drawings of the processing facility. Plot plans specify the location of all equipment and associated structures (pipe racks, buildings) in the facility. Plot plans play a crucial in determining the real estate and space requirements for the plant and hence the cost of the plant. Plot plans are generated during the preliminary design phase but are constantly reviewed and updated as the project progresses. Plot plans are used in every phase of the project and they are used by every project discipline. The use of plot plans by different disciplines is described here.

- Piping: Layout of interconnecting piping systems (pipes and associated fittings).

- Civil engineering: Designing access roads and paths and in locating major support structures. Designing foundations, supports and drainage systems.

- Electrical Engineering: Location of electrical substations, switchgear, routing of cables and motor control centers.

- Instrumentation: Location of main control house, analyzer houses and cable trays.

- Process engineering: Hydraulic design, line sizing, pressure drop and pump requirements.

- Project management/scheduling: Proper and orderly completion of engineering/construction activities. Constructibility reviews and erection sequence of major equipment. Estimating the overall cost of the plant. Review of plant operability, maintenance and safety with the client.

Development of plot plans

The development of plot plans is not an exact science. It varies with the unique requirements of each process plant. The layout designer must anticipate field problems during construction, operation and maintenance. The goal is to produce a safe, cost-effective plant with ease of operation and maintenance.

As the project progresses, the following plot plans are produced in sequence.

- Proposal Plot Plan: This is developed during the estimate phase of the project. It includes only principal equipment, main supporting facilities and overall dimensions. It is used in the estimation of bulk materials and presented to the client for approval of the overall arrangement concept.

- Planning Plot Plan: This is produced after the award of the contract award. The proposal plot plan is reviewed, updated and approved by client. The planning plot plan serves as a working document for the plant layout phase of the project. In the planning plot plan, different areas of the plant are identified and equipment is tagged and positioned at appropriate locations.

- Construction Plot Plan: This is produced as a result of the activities in the plant layout phase of the project. At this stage, all equipment has been sized and positioned. Equipment positions are indicated in terms of coordinate dimensions (North-South, East-West, and Elevations). Additionally, the location of pipe racks, support structures and ancillaries has also been finalized. Locations of access roads, paths and buildings have also been finalized. This is the final plot plan and is used in the construction of the plant.

Sample construction plot plan (Source: “Process Plant Layout and Piping Design”, Ed Bausbacher and Roger Hunt, Prentice Hall).

Documents used in the development of plot plans

- Equipment Lists: Major equipment includes reactors, towers, furnaces, exchangers, pumps, compressors, drums and miscellaneous (lube oil console, corrosion inhibitor packages etc.)

- Process Flow Diagram: Discussed in detail in Module 2.

- Plant Layout Specifications: Discussed earlier in this module.