52896WA Advanced Diploma of Civil and Structural Engineering (Materials Testing)

Investigation of the properties of construction materials, the principles which…Read moreGraduate Diploma of Engineering (Safety, Risk and Reliability)

The Graduate Diploma of Engineering (Safety, Risk and Reliability) program…Read moreProfessional Certificate of Competency in Fundamentals of Electric Vehicles

Learn the fundamentals of building an electric vehicle, the components…Read moreProfessional Certificate of Competency in 5G Technology and Services

Learn 5G network applications and uses, network overview and new…Read moreProfessional Certificate of Competency in Clean Fuel Technology - Ultra Low Sulphur Fuels

Learn the fundamentals of Clean Fuel Technology - Ultra Low…Read moreProfessional Certificate of Competency in Battery Energy Storage and Applications

Through a scientific and practical approach, the Battery Energy Storage…Read more52910WA Graduate Certificate in Hydrogen Engineering and Management

Hydrogen has become a significant player in energy production and…Read moreProfessional Certificate of Competency in Hydrogen Powered Vehicles

This course is designed for engineers and professionals who are…Read more

This manual will give you the tools to approach earthing and shielding issues in a logical and systematic way.

Practical Shielding, EMC/EMI, Noise Reduction, Earthing and Circuit Board Layout

Web Site: www.idc-online.com

E-mail: idc@idc-online.com

Copyright

All rights to this publication, associated software and workshop are reserved. No part of this publication or associated software may be copied, reproduced, transmitted or stored in any form or by any means (including electronic, mechanical, photocopying, recording or otherwise) without prior written permission of IDC Technologies.

Disclaimer

Whilst all reasonable care has been taken to ensure that the descriptions, opinions, programs, listings, software and diagrams are accurate and workable, IDC Technologies do not accept any legal responsibility or liability to any person, organization or other entity for any direct loss, consequential loss or damage, however caused, that may be suffered as a result of the use of this publication or the associated workshop and software.

In case of any uncertainty, we recommend that you contact IDC Technologies for clarification or assistance.

Trademarks

All terms noted in this publication that are believed to be registered trademarks or trademarks are listed below:

IBM, XT and AT are registered trademarks of International Business Machines Corporation. Microsoft, MS-DOS and Windows are registered trademarks of Microsoft Corporation.

Acknowledgements

IDC Technologies expresses its sincere thanks to all those engineers and technicians on our training workshops who freely made available their expertise in preparing this manual.

Who is IDC Technologies?

IDC Technologies is a specialist in the field of industrial communications, telecommunications, automation and control and has been providing high quality training for more than six years on an international basis from offices around the world.

IDC consists of an enthusiastic team of professional engineers and support staff who are committed to providing the highest quality in their consulting and training services.

The Benefits to you of Technical Training Today

The technological world today presents tremendous challenges to engineers, scientists and technicians in keeping up to date and taking advantage of the latest developments in the key technology areas.

- The immediate benefits of attending IDC workshops are:

- Gain practical hands-on experience

- Enhance your expertise and credibility

- Save $$$s for your company

- Obtain state of the art knowledge for your company

- Learn new approaches to troubleshooting

- Improve your future career prospects

The IDC Approach to Training

All workshops have been carefully structured to ensure that attendees gain maximum benefits. A combination of carefully designed training software, hardware and well written documentation, together with multimedia techniques ensure that the workshops are presented in an interesting, stimulating and logical fashion.

IDC has structured a number of workshops to cover the major areas of technology. These courses are presented by instructors who are experts in their fields, and have been attended by thousands of engineers, technicians and scientists world-wide (over 11,000 in the past two years), who have given excellent reviews. The IDC team of professional engineers is constantly reviewing the courses and talking to industry leaders in these fields, thus keeping the workshops topical and up to date.

Technical Training Workshops

IDC is continually developing high quality state of the art workshops aimed at assisting engineers, technicians and scientists. Current workshops include:

Instrumentation & Control

- Practical Automation and Process Control using PLC’s

- Practical Data Acquisition using Personal Computers and Standalone Systems

- Practical On-line Analytical Instrumentation for Engineers and Technicians

- Practical Flow Measurement for Engineers and Technicians

- Practical Intrinsic Safety for Engineers and Technicians

- Practical Safety Instrumentation and Shut-down Systems for Industry

- Practical Process Control for Engineers and Technicians

- Practical Programming for Industrial Control – using (IEC 1131-3;OPC)

- Practical SCADA Systems for Industry

- Practical Boiler Control and Instrumentation for Engineers and Technicians

- Practical Process Instrumentation for Engineers and Technicians

- Practical Motion Control for Engineers and Technicians

- Practical Communications, SCADA & PLC’s for Managers

Communications

- Practical Data Communications for Engineers and Technicians

- Practical Essentials of SNMP Network Management

- Practical Field Bus and Device Networks for Engineers and Technicians

- Practical Industrial Communication Protocols

- Practical Fibre Optics for Engineers and Technicians

- Practical Industrial Networking for Engineers and Technicians

- Practical TCP/IP & Ethernet Networking for Industry

- Practical Telecommunications for Engineers and Technicians

- Practical Radio & Telemetry Systems for Industry

- Practical Local Area Networks for Engineers and Technicians

- Practical Mobile Radio Systems for Industry

Electrical

- Practical Power Systems Protection for Engineers and Technicians

- Practical High Voltage Safety Operating Procedures for Engineers & Technicians

- Practical Solutions to Power Quality Problems for Engineers and Technicians

- Practical Communications and Automation for Electrical Networks

- Practical Power Distribution

- Practical Variable Speed Drives for Instrumentation and Control Systems

Project & Financial Management

- Practical Project Management for Engineers and Technicians

- Practical Financial Management and Project Investment Analysis

- How to Manage Consultants

Mechanical Engineering

- Practical Boiler Plant Operation and Management for Engineers and Technicians

- Practical Centrifugal Pumps – Efficient use for Safety & Reliability

Electronics

- Practical Digital Signal Processing Systems for Engineers and Technicians

- Practical Industrial Electronics Workshop

- Practical Image Processing and Applications

- Practical EMC and EMI Control for Engineers and Technicians

Information Technology

- Personal Computer & Network Security (Protect from Hackers, Crackers & Viruses)

- Practical Guide to MCSE Certification

- Practical Application Development for Web Based SCADA

Comprehensive Training Materials

Workshop Documentation

All IDC workshops are fully documented with complete reference materials including comprehensive manuals and practical reference guides.

Software

Relevant software is supplied with most workshop. The software consists of demonstration programs which illustrate the basic theory as well as the more difficult concepts of the workshop.

Hands-On Approach to Training

The IDC engineers have developed the workshops based on the practical consulting expertise that has been built up over the years in various specialist areas. The objective of training today is to gain knowledge and experience in the latest developments in technology through cost effective methods. The investment in training made by companies and individuals is growing each year as the need to keep topical and up to date in the industry which they are operating is recognized. As a result, the IDC instructors place particular emphasis on the practical hands-on aspect of the workshops presented.

On-Site Workshops

In addition to the quality of workshops which IDC presents on a world-wide basis, all IDC courses are also available for on-site (in-house) presentation at our clients premises.On-site training is a cost effective method of training for companies with many delegates to train in a particular area. Organizations can save valuable training $$$’s by holding courses on-site, where costs are significantly less. Other benefits are IDC’s ability to focus on particular systems and equipment so that attendees obtain only the greatest benefits from the training.

All on-site workshops are tailored to meet with clients training requirements and courses can be presented at beginners, intermediate or advanced levels based on the knowledge and experience of delegates in attendance. Specific areas of interest to the client can also be covered in more detail. Our external workshops are planned well in advance and you should contact us as early as possible if you require on-site/customized training. While we will always endeavor to meet your timetable preferences, two to three month’s notice is preferable in order to successfully fulfil your requirements. Please don’t hesitate to contact us if you would like to discuss your training needs.

Customized Training

In addition to standard on-site training, IDC specializes in customized courses to meet client training specifications. IDC has the necessary engineering and training expertise and resources to work closely with clients in preparing and presenting specialized courses.

These courses may comprise a combination of all IDC courses along with additional topics and subjects that are required. The benefits to companies in using training is reflected in the increased efficiency of their operations and equipment.

Training Contracts

IDC also specializes in establishing training contracts with companies who require ongoing training for their employees. These contracts can be established over a given period of time and special fees are negotiated with clients based on their requirements. Where possible IDC will also adapt courses to satisfy your training budget.

References from various international companies to whom IDC is contracted to provide on-going technical training are available on request.

Some of the thousands of Companies worldwide that have supported and benefited from IDC workshops are:

Alcoa, Allen-Bradley, Altona Petrochemical, Aluminum Company of America, AMC Mineral Sands, Amgen, Arco Oil and Gas, Argyle Diamond Mine, Associated Pulp and Paper Mill, Bailey Controls, Bechtel, BHP Engineering, Caltex Refining, Canon, Chevron, Coca-Cola, Colgate-Palmolive, Conoco Inc, Dow Chemical, ESKOM, Exxon, Ford, Gillette Company, Honda, Honeywell, Kodak, Lever Brothers, McDonnell Douglas, Mobil, Modicon, Monsanto, Motorola, Nabisco, NASA, National Instruments, National Semi-Conductor, Omron Electric, Pacific Power, Pirelli Cables, Proctor and Gamble, Robert Bosch Corp, Siemens, Smith Kline Beecham, Square D, Texaco, Varian, Warner Lambert, Woodside Offshore Petroleum, Zener Electric

Contents

1 Introduction 1

1.1 Introduction 1

1.2 EMI vs EMC 3

1.3 Interference sources 3

1.4 Need for standards 5

1.5 EMC – the issues 6

1.6 Electromagnetic disturbances 7

1.7 EMC testing categories 8

1.8 The compatibility gap 9

1.9 Emission, immunity and compatibility 10

1.10 Causes and consequences of EMI 11

1.11 Levels of compliance and EMC engineering application 12

2 EM principles 14

2.1 Introduction 14

2.2 Coupling paths: sources and victims 14

2.3 Coupling mechanisms 17

2.4 Coupling via the supply network 20

2.5 Electromagnetic fields 21

2.6 Rayleigh/Maxwell near/far fields 22

2.7 Coupling modes 23

2.8 Radiated emissions from PCB (differential mode) 24

2.9 Cable radiated emissions (common mode) 25

2.10 Coupling paths (conducted emissions) 26

2.11 Susceptibility to radiated field coupling 27

2.12 Transient sources 28

2.13 Automotive transients 29

2.14 Supply voltage phenomenon 30

3 EM principles – 2 32

3.1 Introduction 32

3.2 DM/CM conversion 32

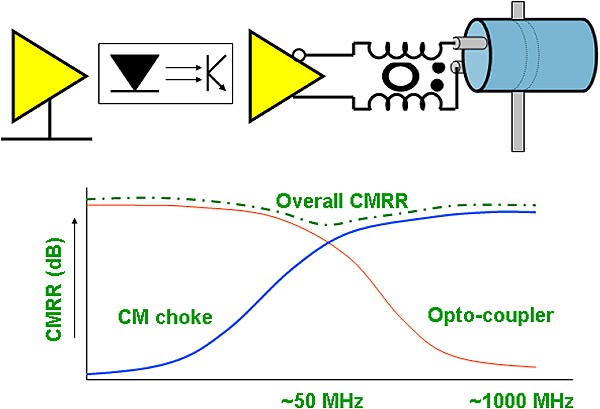

3.3 Common mode rejection ratio (CMRR) 34

3.4 Units in EMC engineering 34

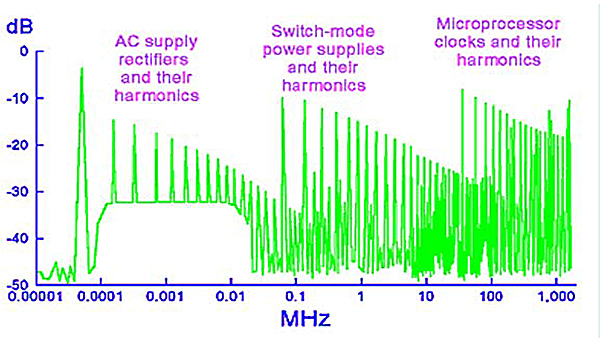

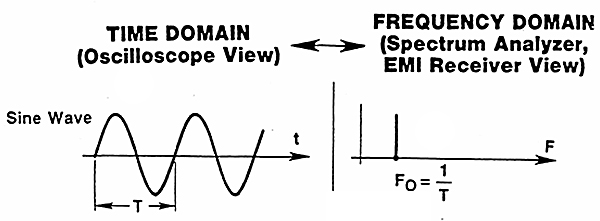

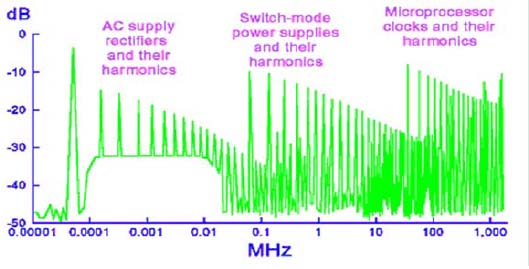

3.5 Spectrum usage and created Interference 36

3.6 Fourier analysis 37

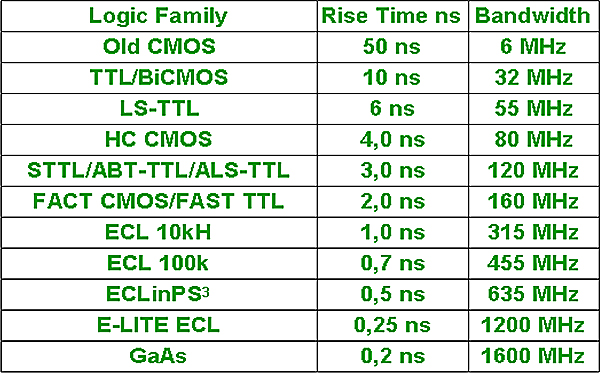

3.7 Choice of logic family 39

3.8 Lightning and ESD bandwidth 39

4 Shielding 40

4.1 Introduction 40

4.2 Shielding and Murphy’s Law 41

4.3 LF magnetic shielding 43

4.4 Apertures and shielding effectiveness 43

4.5 Waveguides 44

4.6 Gasketting and sealing 45

4.7 Panel displays and keyboards 46

4.8 Ventilation and shielding 47

4.9 PCB-level shielding 49

5 Grounding 50

5.1 Introduction 50

5.2 Earth and safety ground 51

5.3 Grounding and frequency 53

5.4 Ground loops 54

5.5 Ground impedance 55

5.6 Ground topologies 55

5.7 Guidelines for grounding 57

6 Cables and connectors 60

6.1 Introduction 60

6.2 Cables in context 61

6.3 Cable parameters and implication 62

6.4 Cable types and frequency 62

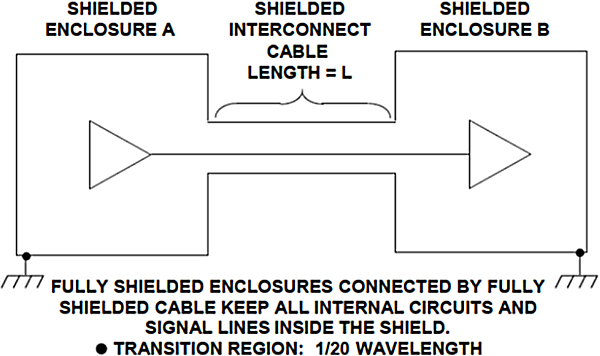

6.5 Cable routing and screening 63

6.6 Types of screening 66

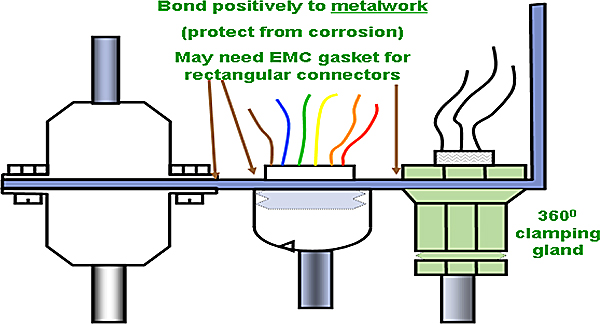

6.7 Screened and unscreened connectors 67

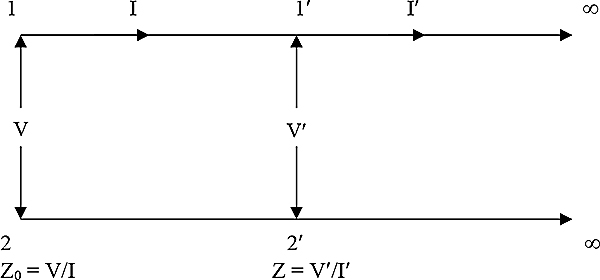

6.8 Transmission lines 69

6.9 Cable coupling to radiated field 71

6.10 Useful references 71

7 Circuits and components 72

7.1 Introduction 72

7.2 Parasitic in passives 73

7.3 Clocking 74

7.4 Choice of logic family 75

7.5 Design and component choice 75

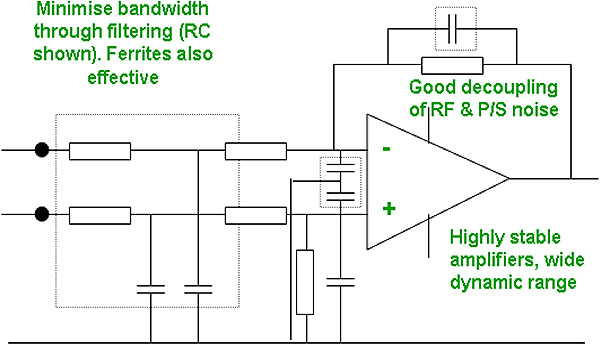

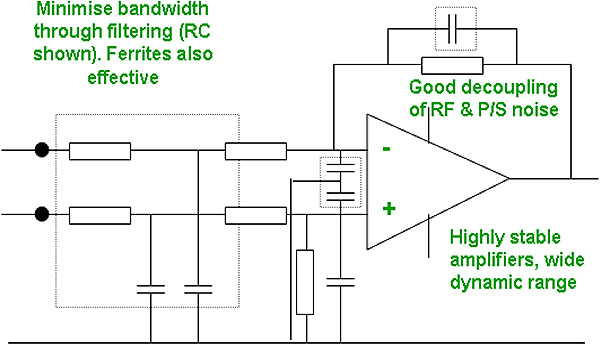

7.6 Analog immunity and demodulation 76

8 Protection and filtering 80

8.1 Introduction 80

8.2 Filter types and operation 81

8.3 Soft ferrites 82

8.4 Thumb rules 83

8.5 Filter specifications 84

8.6 Impedance matching 85

8.7 Filtering precision and Filter earthing 86

8.8 Filters and shielding 87

8.9 Surge protection devices (SPDs) 88

8.10 Surge protection and data integrity 89

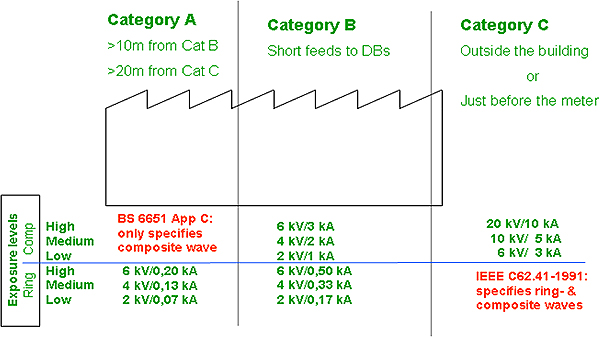

8.11 Surge protection ratings 90

8.12 Surge protection fusing 91

8.13 Positioning SPDs 92

8.14 Electrostatic discharge 93

8.15 Creepage and clearance 94

8.16 Shielding 95

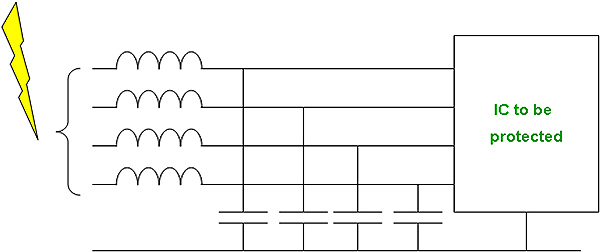

8.17 Signal line protection 97

9 Engineering measurements 99

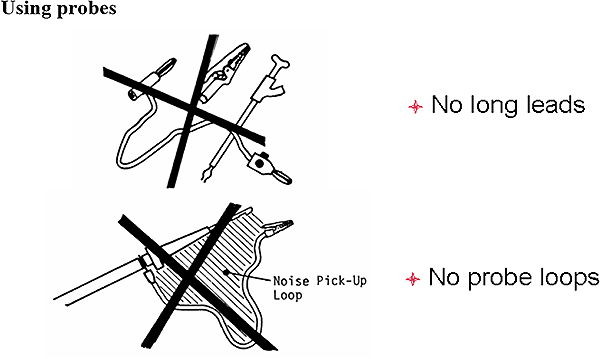

9.1 Introduction 99

9.2 Bench and test laboratory 99

9.3 Determining common mode noise 101

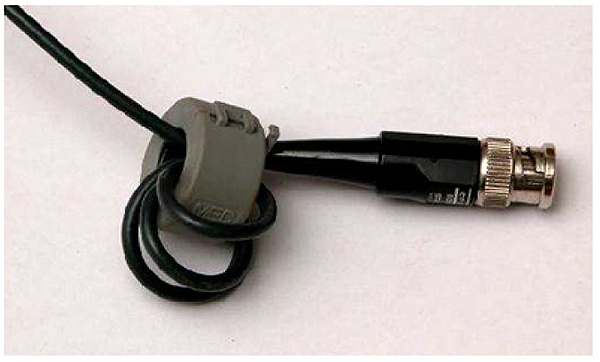

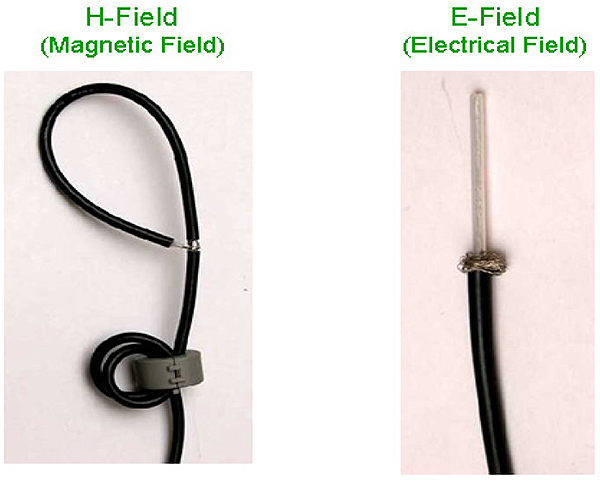

9.4 Field probes 103

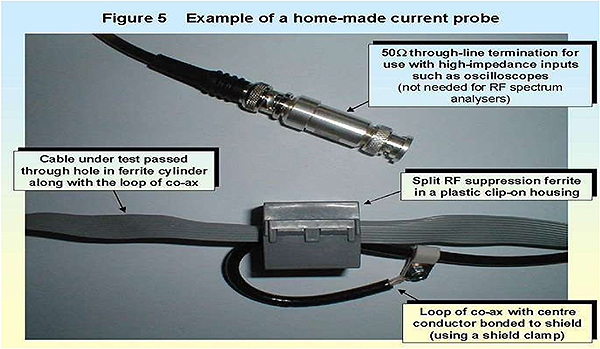

9.5 Common mode and Differential mode currents 105

10 Power supplies 107

10.1 Introduction 107

10.2 PSUs as noise generators 108

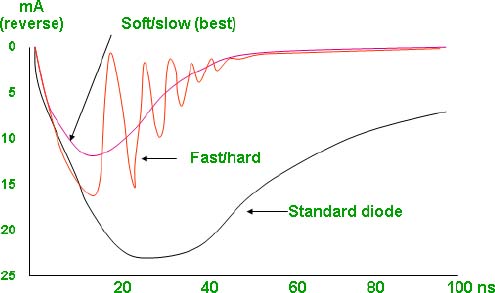

10.3 Switch-mode PSU as a noise generator 109

10.4 Coupling paths, conducted emissions 109

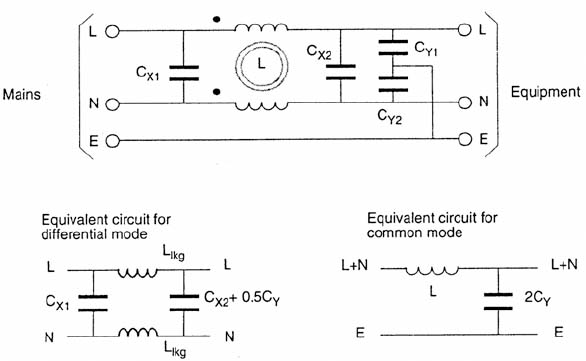

10.5 Power supplies 110

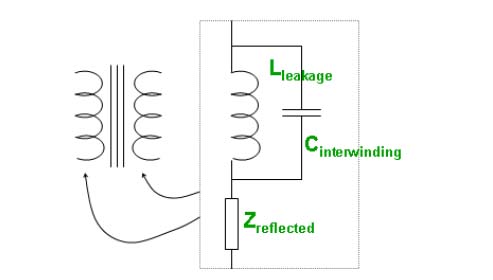

10.6 Parasitic components in SMPS 110

10.7 Effects of diodes 111

10.8 Improvements from inductors 111

10.9 The mains filter 112

10.10 PSU threats 114

11 PCB design and layout 115

11.1 Introduction 115

11.2 Levels of EMC Engineering Application 116

11.3 PCB design objectives 117

11.4 Differential mode coupling 117

11.5 Common mode coupling 118

11.6 Electrical and physical parameters 119

11.7 Board layout 120

11.8 Component and track layout 120

11.9 Areas under control vs outside 121

11.10 Reference planes 122

11.11 The Image Plane effect 123

11.12 Maintaining plane integrity and gridded ground 124

11.13 Board layering 126

11.14 Layer stacking 126

11.15 Grounding on the board 129

11.16 0 V – Chassis Connection 131

11.17 Decoupling Capacitors 132

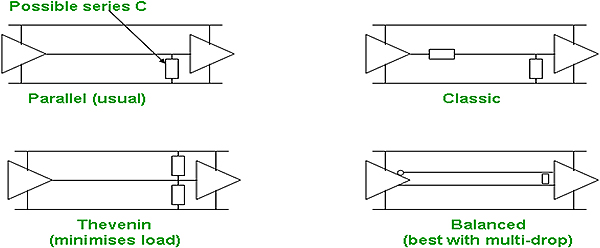

11.18 Transmission Lines on PCBs 134

11.19 Transmission line termination 135

11.20 Multiple boards and backplanes 136

11.21 Interfacing noisy and quite areas 136

12 EMC engineering management 137

12.1 Introduction 137

12.2 Why manage EMC? 137

12.3 Wait and its too late 139

12.4 How to manage EMC 139

12.5 Levels of compliance 141

12.6 EMC lifecycle 142

12.7 Life-cycle flow chart 143

12.8 EMC in context 144

12.9 How much effort? 144

12.10 Co-ordinating efforts 144

12.11 Design practices 145

12.12 EMC engineering implementation 145

12.13 Project management 146

12.14 Need for control plan 146

12.15 Test plans 147

12.16 Test reports (immunity) 149

12.17 Test and calibration of facilities 149

12.18 Maintaining EMC in production 150

13 Conclusion 151

13.1 Introduction 151

13.2 EMC Legalities 152

14 Tutorials 154

15 Practical Exercises 162

16 Powerpoint Slides 178

1.1 Introduction

Electromagnetic Compatibility (EMC) is defined as the ability of a device, equipment or a system to function satisfactorily in its electromagnetic environment without introducing intolerable electromagnetic disturbance to anything in that environment. Any electronic equipment is both capable of emitting unintended signals (i.e., interference to other electronic equipment) and also itself being affected by spurious radiation from other electronic equipment (i.e., interference caused by other electronic equipment). Putting these electronics together without affecting each other is the challenge. Meeting the challenge is a combination of legislation, engineering and consideration for the needs of others.

1.1.1 EMC – accepting the challenge!!!

Historically, EMC has been concerned principally with ensuring the proper operation of collections of electrical and electronic apparatus. Since interference is a function of separation distance, equipment used in close proximity to other equipment had to be compatible with its neighbors. Putting together a system out of several essentially different items of apparatus meant that these items were naturally close to each other, and their Electromagnetic Compatibility (EMC) was necessary in order for the system to work successfully. Hence the discipline of EMC grew up in those industry sectors where system integration was the norm. In the military, the majority of electrical and electronics equipment is used on platforms i.e., ships, aircraft and land vehicles, in their civilian equivalents, aerospace, rail, automotive and marine transport, and in the process control industry. The consumer, IT and professional equipment sectors largely escaped this discipline, because their individual products could assume a large enough separation distance that EMC could be regarded as a luxury rather than a necessity.

Commercial systems that faced issues of safety integrity had often to meet requirements for immunity from various phenomena such as radio frequency (RF) fields, electrostatic discharge (ESD), and various types of conducted transients. But these were contractual requirements, agreed between the equipment suppliers, and the system designers and operators. They were instigated as a result of operational experience, not because of legislation.

There is now an urgent need for mandatory measures to be taken to protect and ensure equipment EMC. Various national administrators have taken ad hoc measures in the past to impose restrictions on some of the electromagnetic properties of some types of products. These measures have often come to be seen as implementing back-door methods of protection, without the technical adequacy of some of the requirements allowing effectively different standards to be applied to imported and indigenous products. In an effort to recognize the need for EMC protection measures and at the same time to eliminate the protectionist barrier to trade throughout the European Community, the European Commission adopted in 1989 a Directive on the approximation of the laws of the Member States relative to electromagnetic compatibility, otherwise known as the EMC Directive.

At times, EMC problems and their solutions do seem like black magic rather than engineering. Here are few of the examples?

- This is an instance from the Falklands war: HMS Sheffield turned off its missile warning RADAR because it interfered with the satellite communication system of the ship. The result of this was – HMS Sheffield was sunk by an enemy missile, which could otherwise have been detected.

- An engineering company installed a CAD system to speed up design time. However, the system crashed so often that they were falling even further behind. Numerous calls to the suppliers failed to solve the problem that everyone thought was software-related. Investigation showed eventually that a large drawing reproduction machine that injected transients onto the mains supply caused it.

- In February ’99, while approaching JFK airport, a DC 10 passenger airplane banked hard left all by itself, almost crashing. The cause of it was suspected to be a CD player being played in 1st class.

- Much of the bad press surrounding CD players and aircraft seems to have originated with a Lufthansa flight where a system operating at 112 MHz had problems which were traced to a CD player with a clock rate of 28 MHz. The system operating frequency is equal to 4 times the clock rate of the CD player.

- A paper mill in Stanger (South Africa) was experiencing trips on its 1 MVA variable speed drive system. A voltage dip of 20%, lasting for more than 40 ms was enough to trip the system and would result in several hours of downtime while the paper web was re-threaded and the system started up again. Installation of a SMES (Superconducting Magnetic Energy Storage System) has meant that there have been no further system trips since 1997.

- In an aerospace factory, a plastic welder was being operated quite legally. Nearby is a mattress factory. Although both are tens of meters away from each other, the welder caused a mattress to burst into flames.

Here is a statement (which may sound familiar) given by the past chairman of the Scottish branch of the Institute of Structural Engineers ‘… the art of modelling materials we do not understand, into shapes we cannot precisely analyse, to withstand forces we cannot properly assess, in such a way that the public at large has no reason to suspect the extent of our ignorance’.

In this workshop, we will be looking at engineering ways to prevent and solve EMC problems without the need for witches, wizards and other supernatural means.

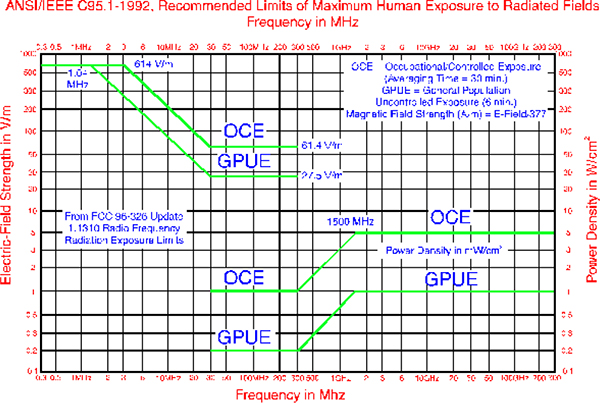

1.2 EMI vs EMC

Electromagnetic interference (EMI) is a serious and increasing form of environmental pollution. Its effects range from extremely small annoyances due to crackles on broadcast reception, to potentially fatal accidents due to corruption of safety-critical control systems. Various forms of EMI may cause electrical and electronic malfunctions, can prevent the proper use of the radio frequency spectrum, can ignite flammable or other hazardous atmospheres, and may even have a direct effect on human tissue. As electronic systems penetrate more deeply into all aspects of society, so both the potential for interference effects and the potential for serious EMI-induced incidents will increase.

The threat of EMI is controlled by adopting the practices of electromagnetic compatibility (EMC). The term EMC has two complementary aspects:

- It describes the ability of electrical and electronic systems to operate without interfering with other systems

- It also describes the ability of such systems to operate as intended within a specified electromagnetic environment

Thus it is closely related to the environment within which the system operates. Effective EMC requires that the system is designed, manufactured and tested with regard to its predicted operational electromagnetic environmental (i.e., the totality of electromagnetic phenomena existing at its location). Although the term electromagnetic tends to suggest an emphasis on high frequency field-related phenomena, in practice the definition of EMC encompasses all frequencies and coupling paths, from DC through mains supply frequencies and microwaves.

1.3 Interference sources

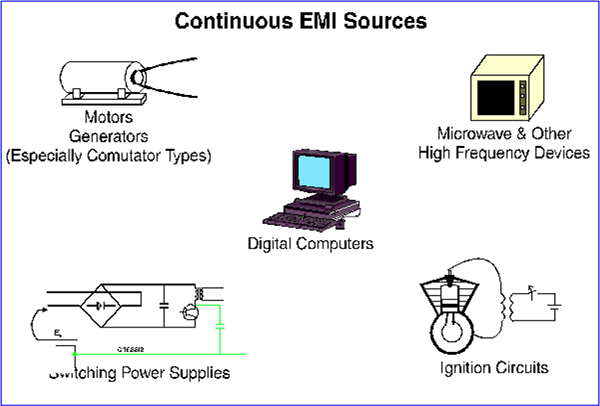

Devices that cause continuous noise

There are two types of internal and external interference, viz., continuous and intermittent. Each type has its own cause.

Continuous interference

Continuous, or Continuous Wave (CW), interference arises where the source continuously emits at a given range of frequencies. This type is naturally divided into sub-categories according to frequency range, and as a whole is sometimes referred to as “DC to daylight”.

- Audio Frequency, from very low frequencies up to around 20kHz. Frequencies up to 100kHz may sometimes be classified as Audio. Sources include:

- Mains hum from: power supply units, nearby power supply wiring, transmission lines and substations.

- Audio processing equipment, such as audio power amplifiers and loudspeakers.

- Demodulation of a high-frequency carrier wave such as an FM radio transmission.

- Radio Frequency Interference (RFI), from typically 20kHz to an upper limit which constantly increases as technology pushes it higher. Sources include:

- Wireless and Radio Frequency Transmissions

- Television and Radio Receivers

- Industrial, scientific and medical equipment (ISM)

- Digital processing circuitry such as microcontrollers

- Broadband noise may be spread across parts of either or both frequency ranges, with no particular frequency accentuated. Sources include:

- Solar activity

- Continuously operating spark gaps such as arc welders

- CDMA (spread-spectrum) mobile telephony

Pulse or transient interference

An electromagnetic pulse (EMP), sometimes called a transient disturbance, arises where the source emits a short-duration pulse of energy. The energy is usually broadband by nature, although it often excites a relatively narrow-band damped sine wave response in the victim.

Sources divide broadly into isolated and repetitive events.

- Sources of isolated EMP events include:

- Switching action of electrical circuitry, including inductive loads such as relays, solenoids, or electric motors.

- Electrostatic discharge (ESD), as a result of two charged objects coming into close proximity or contact.

- Lightning electromagnetic pulse (LEMP), although typically a short series of pulses.

- Nuclear electromagnetic pulse (NEMP), as a result of a nuclear explosion. A variant of this is the high altitude EMP (HEMP) nuclear device, designed to create the pulse as its primary destructive effect.

- Non-nuclear electromagnetic pulse (NNEMP) weapons.

- Power line surges/pulses

- Sources of repetitive EMP events, sometimes as regular pulse trains, include:

- Electric motors

- Gasoline engine ignition systems

- Continual switching actions of digital electronic circuitry.

It is also possible to categorise the different types of EMI by their bandwidth.

- Narrowband: Typically this form of EMI is likely to be a single carrier source – possibly generated by an oscillator of some form. Another form of narrowband EMI is the spurious signals caused by intermodulation and other forms of distortion in a transmitter such as a mobile phone of Wi-Fi router. These spurious signals will appear at different points in the spectrum and may cause interference to another user of the radio spectrum. As such these spurious signals must be kept within tight limits.

- Broadband: There are many forms of broadband noise which can be experienced. It can arise from a great variety of sources. Man-made broadband interference can arise from sources such as arc welders where a spark is continuously generated. Naturally occurring broadband noise can be experienced from the Sun – it can cause sun-outs for satellite television systems when the Sun appears behind the satellite and noise can mask the wanted satellite signal. Fortunately these episodes only last for a few minutes.

The most common causes of continuous interference are:

- 50/60 Hz Supply Power

- Electric Motor (Especially Commutator Type)

- High Power Radio Signals

- Switch Mode Power Supplies

- Microwave Ovens

- Ignition Circuits

Devices that cause constant noise emissions are usually easier to find than intermittent noise problems. This is because the noise doesn’t go away while the system is being looked at. The most common constant noise source is hum, caused by a 50/60 Hz supply power. Supply power is the most common noise component because it is an oscillating voltage, has high power and has a huge antenna system. Almost every system has some form of power filtering for 50/60 Hz supply power. This filtering can take the form of either trying to keep 50/60 Hz noise from getting into our device or leaving the device.

High power electric motors often create wideband noise. They can radiate noise into almost any equipment that is in close proximity to the motor. DC motors often have switch mode power supplies that cause high frequency noise through the common power ground. As motors ramp up and down the noise can vary in frequency and power. This wideband motor noise can then be transmitted back through the power supply lines or through a common earth ground.

Local radio, television stations, radar and ham radio stations can cause radio frequency noise. Military radar is the highest power radio system, but TV, AM and FM local radio stations are usually more common. These stations put out kilowatts of power and often are relatively close to industrial areas.

Switch mode power supplies are fast becoming the most common noise source of all. This is because they are so popular as a low voltage plug pack in home electronics. They create large amounts of harmonic frequencies. The power supplies develop low voltages from mains power by switching the high voltage on and off very quickly that creates lots of noise. The wires that connect the power supply to the device then transmit this noise. Switch mode power supplies are very popular because they are not frequency or voltage dependent and can be used in any country and on almost any device.

Microwave ovens radiate wideband noise by leakage through edges of the door or from the power supply wires. The oven can transmit hundreds of watts over short distances. While this is good for cooking the food, it also can create life-threatening situations for people with pacemakers. Ignition circuits in motorcycles, cars and other gasoline powered motors put out wideband noise created by tens of thousands of Volts. Most automobiles have some sort of suppression circuit, but if this fails it can cause havoc with it’s own electronics and nearby devices. Older motorcycles, lawn mowers and other simple engines often have little or no noise suppression and therefore emit large amounts of noise.

Devices that cause intermittent wideband noise are:

- Lightning

- Switching Relay Equipment

- Arc Welding

- Static

Devices that cause intermittent noise

Intermittent noise components are often hard to find. There is an old saying in electronics… If it’s not broke, it can’t be fixed. And since the noise comes and goes the problem is usually only present part of the time.

Lightning can be the most damaging of the intermittent noise. A typical lightning strike can contain 20 to 40 thousand Amps and millions of Volts. In addition, the lightning strike transmits wideband noise that covers the whole frequency spectrum from DC to X-rays. This, in conjunction with the high current and voltage, makes it impossible to filter out lightning noise. The best method is to keep the lightning away from the circuit by using protection devices like shunts and suppressors.

Turning off relays usually causes relay switching noise. This noise is created by the magnetic field collapsing when the relay is turned off. This type of noise is common in industrial environments.

Arc welding is man-made lightning and has all the attributes of lightning such as high current, high voltage and wideband frequency noise. The advantage here is that it is often very intermittent and can be easily recognized.

Static is very hard to prove as a noise source as it is often invisible and very intermittent. Although is often man-made, it can be natural in origin. Equipment can be spiked by static build up in the air as well as from a person. Static noise is also very similar to lightning with all the same attributes except on a smaller scale.

1.4 Need for standards

Standards are required to control interference from the electronic devices, i.e., to make electronic devices less susceptible to interference. Various countries implemented their own standards, some of the standards are as mentioned below:

- IEC (International Electrotechnical Commission) – the IEC operates in close co-operation with the International Organization (ISO). It is composed of National Committees that are expected to be fully representative of all electrotechnical interests in their respective countries. Two IEC technical committees are devoted full time to EMC work is TC77, Electromagnetic compatibility between equipment including networks, and the International Special Committee on Radio Interference or CISPR.

- CENELEC (European Committee for Electrotechnical Standardization) and ETSI (European Telecommunications Standards Institute) – CENELEC is the European standards making body, which has been mandated by the Commission of the EC (European Commission) to produce EMC standards for the use with European EMC Directive. For Telecommunications equipment ETSI is the mandated standards body. ETSI generates standards for telecom network equipment that is not available to the subscriber, and for the radio communications equipment and broadcast transmitters.

Any manufacturer wanting to market his/her goods into a particular country has to comply with the standards followed by that country.

1.5 EMC – the issues

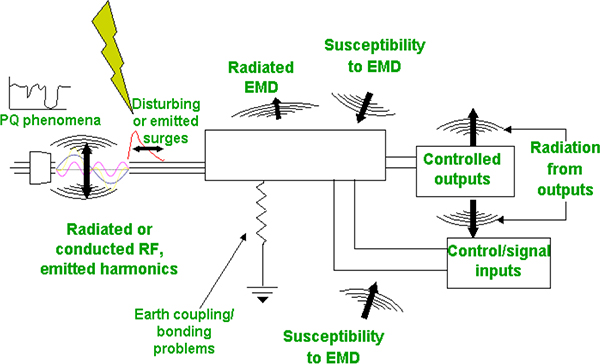

EMC issues

Figure 1.3 shows the EMC issues in a diagrammatic way. Any electronic device will emit radiation in the form of –

- Radiated RF electromagnetic disturbances from the device itself

- Radiated RF electromagnetic disturbances from its input and output connections

- Conducted EMD via its I/O connections or power lines

Any electronic device will be susceptible to EMD from –

- Stray radiation from other electronic equipment

- Stray radiation from the I/O of other electronic equipment

- Conducted disturbances via mains lines or I/O, or

- Mains voltage variations or waveshape

1.6 Electromagnetic disturbances

Any electromagnetic phenomenon may degrade the performance of the system. Some of the electromagnetic issues are as mentioned below:

Voltage fluctuations: short-term (sub-second) fluctuations with quite small amplitudes are annoyingly perceptible on electric lightning, though electronic power supply circuits comfortably ignore them. Generation of flicker by high power load switching is subject to regulatory control.

Waveform distortion: at source, the AC mains is generated as a pure sine wave but the reactive impedance of the distribution network together with the harmonic currents drawn by non-linear loads causes voltage distortion. Power converters and electronic power supplies are important contributors to non-linear loading. Harmonic distortion may actually be worse at points remote from the non-linear load because of resonance in the network components. Not only must non-linear harmonic currents be limited but also equipment should be capable of operating with up to 10% total harmonic distortion in the supply waveform.

Voltage variations: the distribution network has finite source impedance and varying loads will affect the terminal voltage. Not including voltage drops within the customer’s premises, an allowance of ±10%, on the nominal voltage will cover normal variations in the UK. The effect of the shift in nominal voltage from 240 V to 230 V, as required by CENELEC Harmonization Document HD 472 S1: 1988 and implemented in the UK by BS 7697: 1993, is that from 1st January 1995 the UK nominal voltage is 230 V with a tolerance of +10%, –6%. After 1st January 2003 the nominal voltage will be 230 V with a tolerance of ±10%, in the line with all other Member States.

Transients and surges: switching operations generate transients of a few hundred volts as a result of current interruption in an inductive circuit. These transients normally occur in bursts and have risetimes of no more than a few nsec, although the finite bandwidth of the distribution network will quickly attenuate all but local sources. High amplitude spikes in excess of 2 kV may be observed due to fault conditions. Even higher voltage surges due to lightning strikes occur – mostly on exposed overhead line distribution systems in rural areas.

Voltage interruptions: faults on power distribution systems cause almost 100% voltage drops but are cleared quickly and automatically by protection devices, and throughout the rest of the system the voltage immediately recovers. Most consumers therefore see a short voltage dip. The frequency of occurrence of such dips depends on location and seasonal factors.

- Supply voltage – Mains electricity suffers a variety of disturbing effects during its distribution. These may be caused by sources in the supply network or by other users, or by other loads within the same installation. A pure, uninterrupted supply would not be cost effective; the balance between the cost of the supply and its quality is determined by national regulatory requirements, tempered by the experience of the supply utilities. Typical disturbances are:

- # Interruptions

- # Dips

- # Surges

- # Waveform distortion

- # Fluctuations

- # Voltage imbalance

- # Frequency variations

- # DC in AC networks

- # Power-line carrier signaling

- Transient overvoltages – transient overvoltages on supply, signal and control lines that may occur because of lightning, switching or ESD (electrostatic discharge) can degrade the system performance. Take an example of an EMC phenomenon caused because of an ESD transient. An ESD transient can corrupt the operation of a microprocessor or clocked circuit just as a transient coupled into the supply or a signal port.

- Radio frequency fields – radio frequency fields, pulsed (radar), modulated and continuous, coupled directly into the equipment or onto its connected cables, may also degrade the system performance to a great extent.

- NEMP (nuclear electromagnetic pulse) – this is the effect of a high altitude nuclear explosion, which generates a sub-nanosecond nuclear electromagnetic pulse (NEMP) that is disruptive over an area of hundreds of square kilometers.

- LF magnetic or electric fields

1.7 EMC testing categories

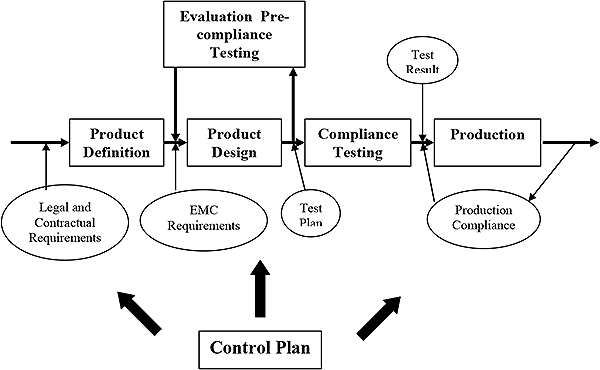

Figure 1.4 shows the diagrammatic view of the EMC testing categories. The four categories are as follows:

- Conducted Emission (CE)

- Conducted Susceptibility (CS)

- Radiated Emission (RE)

- Radiated Susceptibility (RS)

EMC testing categories

All electronic devices are susceptible to electromagnetic disturbances, if it is not the case, then there would be no EMC issue. However, none of the electronic devices are completely immune and so the EMC problem still exists. Electromagnetic Susceptibility can be defined as the inability of a device, equipment or a system to perform without degradation in the presence of an electromagnetic disturbance. On the other hand, immunity to electromagnetic disturbances can be defined as the ability of a device, equipment or a system to perform without degradation in the presence of an electromagnetic disturbance.

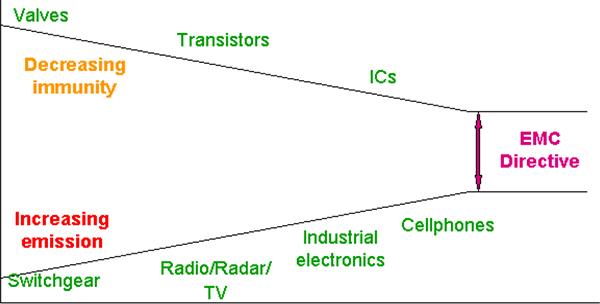

1.8 The compatibility gap

The increasing susceptibility of electronic equipment to electromagnetic influence is being paralleled by an increasing pollution of the electromagnetic environment. Susceptibility is a function of the adoption of VLSI technology in the form of microprocessors, both to achieve new tasks and for those that were previously tackled by electromechanical or analog means, and the accompanying reduction in the energy required of potentially disturbing factors. It is also a function of the increased penetration of radio communications, and the greater opportunities for interference to radio reception that result from the co-location of unintentional emitters and radio receivers.

At the same time more radio communications means more transmitters and an increase in the average RF field strengths to which equipment is exposed. Also, the proliferation of digital electronics means an increase in low-level emissions that affect radio reception – a phenomenon that has been aptly described as a form of electromagnetic smog. Only legislation to limit the effects of interaction can solve the problem.

Compatibility gap

These concepts can be graphically presented in the form of a narrowing electromagnetic compatibility gap, as shown in Figure 1.5. This gap is of course conceptual rather than absolute, and the phenomena defined as emissions and those defined as immunity do not mutually interact except in rare cases. But the maintenance of some artificially-defined gap between equipment immunity and radio transmissions on the other hand, and equipment emissions and radio reception on the other, is the purpose of the application of EMC standards, and is one result of the enforcement of the EMC directive.

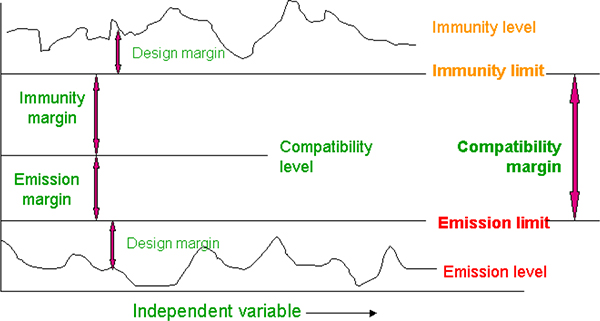

1.9 Emission, immunity and compatibility

Relation between emission, immunity and compatibility is as shown by graphical representation in Figure 1.6. As shown in the Figure, there are 3 different levels:

- The lowermost level is the Emission level; the maximum level in emission level is the emission limit. The emissions from the devices should be within this level and it should not exceed the emission limit.

- The uppermost level is the Immunity level; the minimum level in the immunity level is the immunity limit. The immunity of the devices should be within this level and it should not be less than the immunity limit.

- The middle level is the Compatibility level; the difference between the Immunity limit and the Emission limit is the Compatibility Margin. Greater the compatibility margin, lesser the chances of EMC problems.

For proper functioning of a system, the devices should be compatible (with respect to EM environment) and hence the term Compatibility.

Emission, Immunity and Compatibility

1.10 Causes and consequences of EMI

The consequences of EMI can be classified in different categories depending on its criticality. Some of the causes of EMI that results into these consequences are mentioned below:

- Malfunction of a safety-critical item of machinery

- Erratic operation of moving equipment

- A safety device to ignore a signal

- An operation to stop for no apparent reason

- Not carry out its intended function, but not cause any havoc as a result

The malfunction will fall into the below mentioned classifications depending on the type of damage or loss occurred.

- Catastrophic – death, major injuries, downstream consequences

- Critical – minor injuries, extensive damage

- Major – minor permanent damage

- Minor – temporary performance loss

- Inconsequential – loss of performance within tolerance, no human intervention needed

1.10.1 Test result classification

For an item of equipment to pass a test, the test result must be determined beforehand. An important part of achieving compliance with any regulation is that the specification details what will happen under EMI conditions. The test result can be classified as follows:

- Normal performance within specified limits

- Self-recoverable temporary degradation or loss of function

- Temporary degradation or loss of function that requires human intervention or system reset

- Degradation or loss of function due to physical damage; software or data corruption

1.11 Levels of compliance and EMC engineering application

1.11.1 Levels of compliance

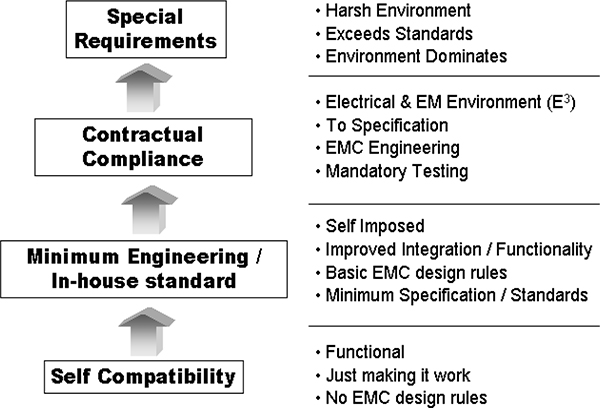

There are different levels of EMC engineering. Figure 1.7 shows the compliance structure showing different levels at which designers and companies operate.

Levels of compliance

The four levels of compliance are as follows:

- Self-compatibility

- Minimum engineering/in-house standard

- Contractual compliance

- Special requirements

The above is useful to appreciate the change in engineering strategy – say a company was just struggling to make things works, but must now it must comply with specifications.

1.11.2 Levels of EMC engineering application

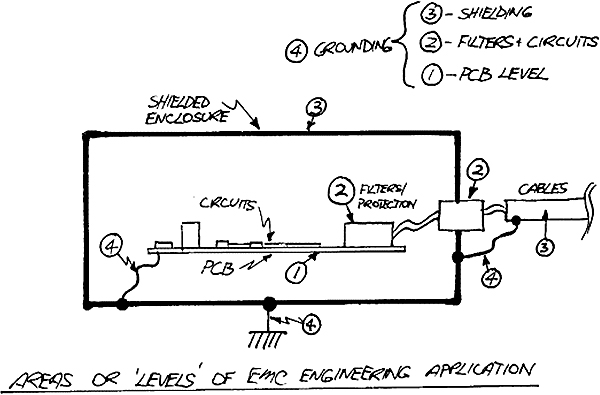

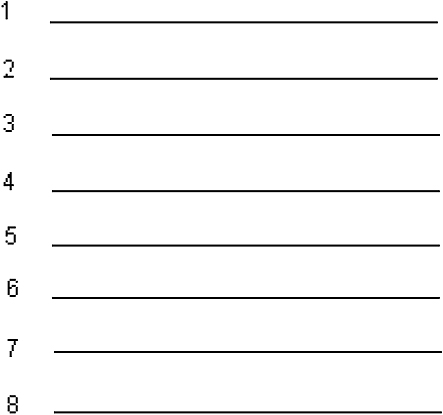

This course aims to equip with tools to design for and reduce EMI. Three main areas of application will be dealt with:

- PCBs

- Circuits/filters

- Screening

Levels of EMC Application Engineering

Proper grounding is underlying to all of the above areas and is also dealt with. Figure 1.8 shows the different areas.

PCBs can be seen as the inner or primary line of defence. The circuits on PCBs are where EMI problems eventually start and end. Proper PCB layout is the most subtle and cost effective way of influencing EMI. It controls EMI coupling right at the source or receptor – the circuit.

Filters and special circuits are used around the inner PCB as a secondary control measure or line of defence. When a PCB layout only does not eliminate unwanted interference, extra circuits and filters are added. Extra circuits imply more real estate and costs. Protection devices and circuits fall into this category.

Shielding is the tertiary or outer line of defence. This includes cables, screens and enclosures. If both of the above areas of application do not suffice, shielding is needed. The least cost effective solution and sometimes a last brute force attempt at compliance.

The fourth area of application (although not a level) is grounding. It determines the effectiveness and way all three levels interact. Grounding is applicable to all three of the above areas. Grounding on PCB level between different types of circuits is crucial. Filters/protection do not work properly if poorly grounded. Grounding of cable screens and enclosures has a primary influence on its shielding effectiveness.

2.1 Introduction

Electromagnetic interference (EMI) is caused in the presence of two parties, viz., a source and a victim. The source of interference is the aggressive circuits. High speed, noisy or dirty circuits come under the category of aggressive circuits. These are the noise generating circuits that also cause interference. The victims are sensitive circuits that are susceptible to interference. Sensitive, clean and quiet circuits come under the category of victim circuits. Any electronic device has the potential to radiate or conduct emission, and at the same time, they themselves are susceptible to it. In some cases, a victim itself acts as a source of interference. It is very important to understand which of the circuits (or modules) come under the category of ‘source’ and/or ‘victim’. Understanding such a mechanism helps in solving EMC problems.

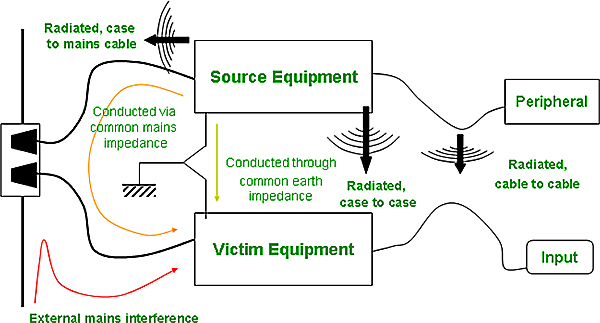

2.2 Coupling paths: sources and victims

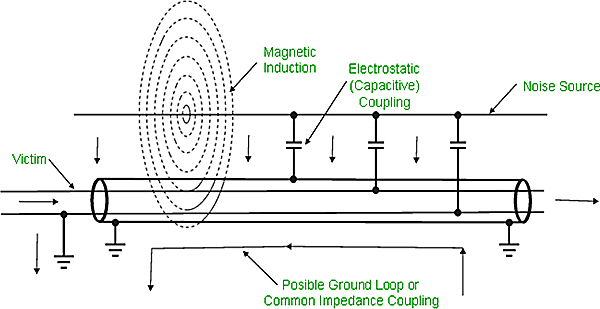

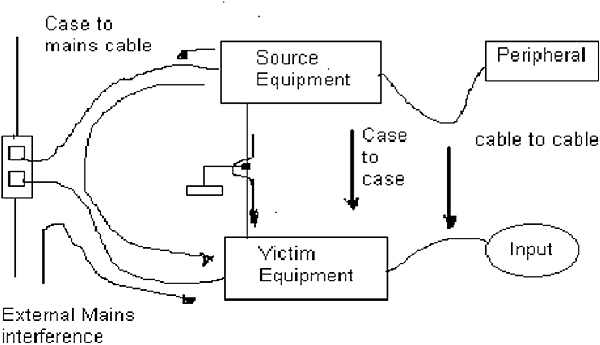

Figure 2.1 shows the potential interference routes that exist from one to the other when source and victim are put together. When the systems are built, it is necessary to know the emission signature and susceptibility of the component (equipment), along with problems that are likely to be experienced with close coupling. Following the published emission and susceptibility standards does not ensure freedom from system EMC problems. Standards are written for protecting a particular service, in the case of emissions, these are radio broadcast and telecommunications – they have to assume a minimum separation distance between source and victim. Most electronic devices consist of elements that are capable of antenna-like behaviour (i.e., they tend to radiate) such as cables, PCB tracks, internal wiring and mechanical structures. These elements can unintentionally transfer energy in the form of either electric, magnetic or electromagnetic fields that couple with the circuits. In practical situations, intra-system and external coupling between equipment is generally modified by the presence of screening and dielectric materials, and by the layout and proximity of interfering and victim equipment and especially their respective cables. Ground or screening planes tend to enhance interfering signal by reflection or attenuate it by absorption. Cable-to-cable coupling can be either inductive or capacitive and it depends on orientation, length and proximity. In most practical situations, dielectric materials may also reduce the field by absorption, though this is negligible compared to the effects of conductors.

Coupling paths: sources and victims

2.2.1 Universal interference model

Universal interference model

Figure 2.2 shows the working of EMI in the form of Universal Interference Model. It shows that there is always a noise source (i.e., culprit), receptor (i.e., victim) and coupling path (i.e., interference path).

The solution for reducing interference can be at the source, receptor or coupling path. The following are the means the reduce interference:

- Remove or reduce noise at source – low noise design, shielding, decoupling, etc.

- Improve victim immunity – high immunity design, shielding, filtering, decoupling, etc.

- Remove or attenuate coupling path – isolation, re-routing, shielding, spacing, filtering, etc.

2.2.2 Noise sources

Noise sources are present everywhere, some of the sources of noise are as mentioned below:

- RF Transmitters – anything that generates RF are the sources of noise. Telemetry, Mobile phones, Radar, X-ray equipment, etc. are the applications that generates RF energy.

- Receivers – anything that has PLL (Phase Locked Loop) or clock are sources of noise. Local Oscillators, Computer and Peripherals come under this category.

- Anything that switches current is source of noise. Equipments such as Motors, SMPS (Switch Mode Power Supply), Power Lines, Engine Ignition, Fluorescent Lights, etc. come under this category.

- Anything that causes Arc is source of noise. Arc Welders, Motors, Relays, etc. come under this category.

- Natural – Galastic Noise, Lightning, Atmospheric noise, etc. are also the sources of noise.

2.2.3 Receptors

Receptors are present everywhere and some of the victims (receptors) are as mentioned:

- Anything intended for RF reception or using tuned circuits may be victims. Telemetry Receivers, Radar, etc. are victims to noise.

- Anything that can be disturbed by shifting logic levels, timing or clock disturbances, memory or data line toggling, etc. Digital electronics, software, etc. fall under this category.

- Any sensitive circuit such as Analog electronics that can amplify, rectify, saturate, shift levels, etc. are victims.

- Sensitive materials like Fuel, Ammunition that has risk of burning, exploding also proves victims to noise.

- Biological hazards to human beings (in this case, human beings are victims).

2.2.4 Coupling media

The below mentioned are the considerations to be made while changing the coupling between source and victim.

- Space separation

- Shielding materials

- Absorptive materials

- Cables

- Ground inter coupling

- Filters and circuits

- Power lines

2.3 Coupling mechanisms

There are many ways in which the electromagnetic interference can be coupled from the source to the receiver. Understanding which coupling method brings the interference to the receiver is key to being able to address the problem.

- Radiated: This type of EMI coupling is probably the most obvious. It is the type of EMI coupling that is normally experienced when the source and victim are separated by a large distance – typically more than a wavelength. The source radiates a signal which may be wanted or unwanted, and the victim receives it in a way that disrupts its performance.

- Conducted : Conducted emissions occur as the name implies when there is a conduction route along which the signals can travel. This may be along power cables or other interconnection cabling. The conduction may be in one of two modes:

- Common mode: This type of EMI coupling occurs when the noise appears in the same phase on the two conductors, e.g. out and return for signals, or +ve and -ve for power cables.

- Differential mode: This occurs when the noise is out of phase on the two conductors.

- The filtering techniques required will vary according to the type of EMI coupling experienced. For common mode lines are filtered together. For differential mode they may be filtered together.

- Inductive coupling: What is normally termed inductive coupling can be one of two forms, namely capacitive coupling and magnetic induction.

- Capacitive coupling : This occurs when a changing voltage from the source capacitively transfers a charge to the victim circuitry.

- Magnetic coupling: This type of EMI coupling exists when a varying magnetic field exists between the source and victim – typically two conductors may run close together (less than λ apart). This induces a current in the victim circuitry, thereby transferring the signal from source to victim.

By determining the form of coupling that exists and the way in which it is reaching the victim, it may prove to be that the most effective method of reducing the EMI is by putting measures in place to reduce the coupling and reduce the level of interference to an acceptable level.

Electromagnetic interference, EMI is present in all areas of electronics. By understanding the source, the coupling methods and the susceptibility of the victim, the level of interference can be reduced to a level where the EMI causes no undue degradation in performance.

Any EMI problem will involve any or a combination of the below mentioned coupling mechanism.

- Common impedance (Conducted)

- Capacitive (Electrostatic)

- Inductive (Magnetic)

- Electromagnetic (Radiated)

2.3.1 Common impedance (conducted)

From Figure 2.3, when an interference source (i.e., output of system A) shares a ground connection with a victim (i.e., input of system B) then any current due to A’s output flowing through the common impedance section (denoted by inductance L in Figure 2.3) develops a voltage in series with B’s input. The common impedance need not be more than a length of wire or pcb track, but high frequency or high di/dt components in the output will couple more efficiently because of the inductive nature of the impedance. The voltage developed across an inductor as a result of current flow through it is given by the equation 1 below:

V = –L×dIL/dt …………….(1)

where, L is the self inductance in H (Henries).

The output and input may be part of the same system; in this case there is a spurious feedback path through the common impedance that can cause oscillation. The solution as shown in Figure 2.3 is to simply re-route the connections so that there is no common current path, and hence no common impedance between the two circuits. The only penalty for doing this is the requirement for extra wiring or track to define the separate circuits. This applies to any circuit that may include common impedance (such as power rail connections). Grounds are most usual source of common impedance because the ground connection (generally not shown on circuit diagrams) is often taken for granted.

Conductive connection (common mode coupling)

2.3.2 Inductive (magnetic)

Magnetic induction

AC current flowing in a conductor creates a magnetic field that will couple with a nearby conductor and induce a voltage in it as shown in Figure 2.4. The voltage induced in the victim conductor is now given by equation 2 below:

Vn = –M×dIL/dt …………….(2)

where, M is mutual inductance in H (Henries).

Notice the similarity between equation 2 and equation 1; M depends on the areas of the source and victim current loops, their orientation and separation distance, and the presence of any magnetic screening. Whether or not there is a direct connection between the two circuits, the coupling remains unaffected; the induced voltage would be the same even if the circuits were isolated or connected to ground.

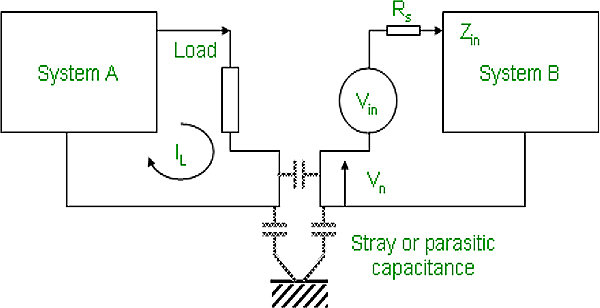

2.3.3 Capacitive (electrostatic)

Electrostatic coupling

Changing voltage on one conductor creates an electric field that may couple with a nearby conductor and induce a voltage on it, as shown in Figure 2.5. The voltage induced on the victim conductor is given by equation 3 below:

Vn = CC × dVL/dt × Zin//RS …………….(3)

where, CC is the coupling capacitance,

Zin//RS is the impedance to ground of the victim circuit.

This assumes that the impedance of the coupling capacitance is much higher than that of the circuit impedances. The noise is injected as if from a current source with a value of CC . dVL/dt. The value of CC is a function of the distance between the conductors, their effective areas and the presence of any electric screening material.

2.3.4 Real world coupling

A combination of coupling mechanisms exists in the real world. One type of coupling can dominate, but sometimes a combination is present as shown in Figure 2.6.

Real world coupling

2.3.5 Mutual C and L vs Lead Spacing

Both mutual capacitance and inductance are affected by the physical separation of the source and victim conductors. Figure 2.7 is the graph showing the effects of the spacing between conductors on their ability to couple from one circuit to another.

Mutual capacitance and inductance V/s Lead spacing

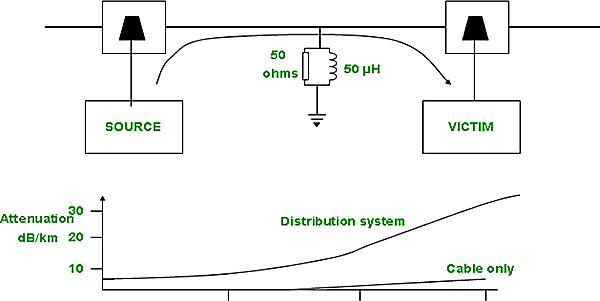

2.4 Coupling via the supply network

Propagation of interference from a source to a victim can take place via the mains distribution network to which both are connected. This is not well characterized at high frequencies, since the electrical loads connected can present virtually any RF impedance at their point of connection. From Figure 2.8 we can see that the RF impedance presented by the mains can approximate a network of 50 Ω in parallel with 50 μH on the average. For short distances (such as that between adjacent outlets on the same ring) coupling via the mains connection of two items of equipment can be represented by the Figure 2.8.

Coupling via the supply network

Over longer distances, power cables are fairly low loss transmission lines having characteristic impedance of about 150-200 Ω up to about 10 MHz. However, in any local power distribution system the disturbances and discontinuities introduced by load connections, cable junctions and distribution components dominates the RF transmission characteristic, in turn these all tends to increase the attenuation.

2.5 Electromagnetic fields

Two conductors at different potentials generate an electric field (E field) between them. The field is proportional to the applied voltage divided by the distance between the conductors and is measured in volts per meter (V/m).

A conductor carrying a current generate magnetic field (H field) around it. The field is proportional to the current divided by the distance from the conductor and is measured in amps per meter (A/m).

When an alternating voltage generates an alternating current through a network of conductors (this description applies to any electronic circuit), an electromagnetic (EM) wave is generated that propagates as a combination of E and H fields. The speed of propagation of EM wave is determined by the medium (in free space it is equal to the speed of light, i.e., 3×108 m/s). Near to the radiating source, the geometry and strength of the fields depend on the characteristics of the source. A circuit node carrying a significant dv/dt (rate of change of voltage) will generate mostly an electric field; a conductor carrying a significant di/dt (rate of change of current) will generate mostly a magnetic field. The structure of these generated fields will be determined by the physical layout of the source conductors, as well as by other conductors, dielectrics and permeable materials in the vicinity. Further away from the source, the complex three-dimensional field structure decays and only the components that are orthogonal to each other and to the direction of propagation remain. Figure 2.9 demonstrates these ideas graphically.

Electromagnetic fields

2.6 Rayleigh/Maxwell near/far fields

Wave Impedance, and Rayleigh and Maxwell distances for transition to far field

The ratio of the electric to magnetic field strengths (i.e., E/H) is called the wave impedance (Figure 2.10). The wave impedance is a key parameter of any given wave as it determines the efficiency of coupling with another conducting structure, and also the effectiveness of any conducting screen that is used to block it. Radiated emissions can be divided into near field and far field.

In the far field, i.e., for d > λ/2π, the wave is known as a plane wave and the E and H fields decline with distance at the same rate. Therefore its impedance is constant, and is equal to the impedance of free space given by equation 4:

Zo = √μo/ɛo = 120π = 377 Ω …………….(4)

where, μo = 4π . 10-7 H/m, permeability of free space

ɛo = 8.85 . 10-12 F/m, permittivity of free space

In the near field, i.e., for d < λ/2π, the wave impedance is determined by the characteristics of the source. Separate electric and magnetic field exist and which one will predominate depends on the source impedance. A low current, high voltage radiator such as a rod will mainly generate an electric field of high impedance, while a high current, low voltage radiator such as a loop will mainly generate a magnetic field of low impedance. As a special case, if the radiating structure happens to have impedance around 377Ω, then depending on the geometry, a plane wave can be generated in the near field.

The region around λ/2π (approximately one sixth of a wavelength) is the transition region between near and far fields. It indicates the region within which the field structure changes from complex to simple. Plane waves are always assumed to be in the far field, while if you are looking at the near field it is necessary to consider individual electric or magnetic fields separately.

2.6.1 The Rayleigh criterion

There is another definition of the transition between near and far fields determined by the Rayleigh range. This has to do nothing with the field structure according to Maxwell’s equation, but with the nature of the radiation pattern from any physical antenna (or equipment under test) that is too large to be a point source. For the far field assumption to hold, the phase difference between the fields components radiated from the ends of the antenna must be small and therefore the path difference to these ends must also be small in comparison to a wavelength. This produces a criterion that associates the wavelength and the maximum dimension of the antenna (or equipment under test) to the distance from it. Using the Rayleigh criterion, the far field is defined as beyond a distance:

d > 2D2/λ ……………….(5)

where, D is the maximum dimension of the antenna.

Table above shows a comparison of the distances for the two criteria for the near field/far field transition for various frequencies and EUT (Equipment Under Test) dimensions.

2.7 Coupling modes

The fundamental to an understanding of EMC are the concepts of differential mode, common mode and antenna mode radiated field coupling. They apply to coupling of both emissions and interference.

2.7.1 Differential mode

In most cases, the wanted signal is produced in differential mode. Consider two items of equipment interconnected by a cable as shown in Figure 2.11. The cable carries signal currents in differential mode (go and return) down the two wires in close proximity. A radiated field can couple to this system and induce differential mode inteference between the two wires. Similarly, the differential current will induce a radiated field of its own. The ground plane plays no role in this coupling.

2.7.2 Common mode

The cable also carries currents in common mode, i.e., all flowing in the same direction of each wire as shown in Figure 2.11. These currents very often have nothing at all to do with the signal currents. They may be induced by an external field coupling to the loop formed by the cable, the ground plane and the various impedances connecting the equipment to ground, then may cause internal differential currents (to which the equipment is susceptible). Unconventionally, they may be generated by internal noise voltages between the ground reference point and the cable connection, and are responsible for radiated emissions. The stray capacitances and inductances associated with the wiring and enclosure of each unit are an integral part of the common mode coupling circuit and play a major role in determining the amplitude and spectral distribution of the common mode currents. These stray impedances are incidental rather than designed in to the equipment. They don’t appear on any circuit diagram and are difficult to control or predict.

Radiated coupling modes

2.7.3 Antenna mode

Antenna mode currents are carried in the same direction by the cable and the ground reference plane as shown in Figure 2.11. They should not originate as a result of internally generated noise, but they will flow when the whole system (including the ground plane) is exposed to an external field. Example – When an aircraft flies through the beam of a radar transmission, it carries the same currents as the internal wiring. Antenna mode currents only become a puzzle for the radiated field susceptibility of independent systems when they are converted into other modes (i.e., differential or common mode) by varying impedances in the different current paths.

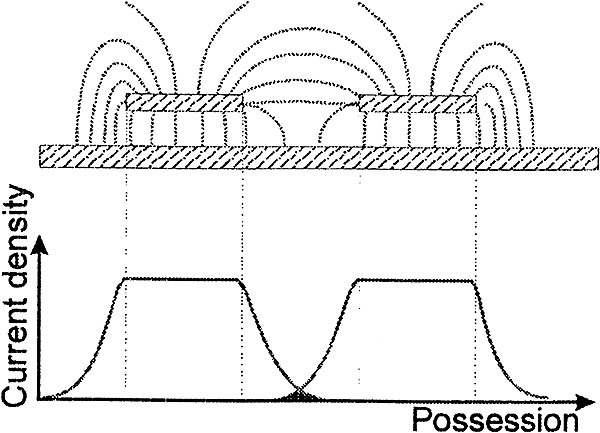

2.8 Radiated emissions from PCB (differential mode)

In most equipment, the primary sources are currents flowing in circuits such as clocks, oscillators, etc that are mounted on the PCB, some of the energy that is directly radiated from the PCB is modeled as a small loop antenna carrying the interference current. Figure 2.12 describes this situation. A small loop is that which has dimension smaller than a quarter wavelength (λ/4) at the frequency of interest (typical example – 1meter at 75 MHz). When the dimension of the loop approach λ/4 the currents at different points on the loop appear to be out of phase at a distance, so that the effect is to reduce the field strength at any given point. The electric field strength varies with the square of the frequency, and is directly proportional to the signal current and loop area.

E = 263 × 10-12 × (f2 × A × Is) V/m …………………(6)

where, A is loop area in cm2,

f (MHz) is the frequency of Is the source current in mA.

From equation 6, it is clear that the field strength increases with the loop area. The loop area is the path traced by the signal current along with the return path. For the field strength to be as small as possible, the loop area should be small, so one of the rules in PCB design and layout is to keep the area covered by the signal current as small as possible (keep the loop areas small). Keep the signal return path as simple and clear as possible. Avoid puzzling and persistent signal paths as it may cover a large unintended area and that in turn results in increased field strength.

The loop antenna not only acts as a source of emission of unwanted noise but also can receive unwanted noise and in turn is the victim of interference. This is one of the main reason of using gridded grounds and ground planes, which ensures a defined return path for signal currents and avoids any unintentional return paths.

Radiated emissions from PCB (differential mode)

2.9 Cable radiated emissions (common mode)

Differential mode radiations from small loops on PCBs are not the only contributor to radiated emission; common mode currents flowing on the PCB and on attached cables can contribute much more in comparison. The differential mode currents that are governed by Kirchoff’s current law can be easily predicted, in contrast with the common mode currents on the PCB are not easy to predict. Figure 2.13 shows the return path for common mode currents is via stray capacitance (displacement current) to the other nearby objects.

Cable radiated emissions (Common mode)

The full prediction would therefore have to take into account the detailed structure (mechanical) of the PCB and its case, its proximity to ground and to other equipment. The interference current generated in common mode from ground noise developed across the PCB or elsewhere in the equipment and may flow along the conductors or along the shield of the shielded cable. Here even if the cables are longer than λ/20, it will act as an antenna. The common mode noise generally couple through parasitic capacitances.

The equation of field strength in case of common mode is as follows:

E = 1.26 × 10-4 × (f × L ×ICM) V/m ……………..(7)

where, L is the cable length in meters,

ICM is the common mode current at f MHz in mA flowing in the cable.

Here if the length of the cable increases, the field strength increases proportionally. In PCB design and layout, steps should be taken to reduce the common mode currents (minimize common mode currents). Partitioning, filtering, grounding and using planes in PCB design can achieve this.

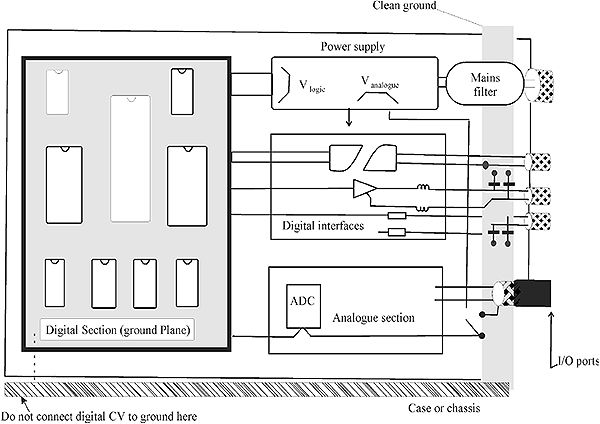

2.10 Coupling paths (conducted emissions)

As in Figure 2.14, where there are high switch-mode frequencies, parasitic capacitance to ground plays a major part. This allows large common-mode voltages to develop relative to ground. In addition, differential mode signals can appear on the supply line or the signal cable as a result of SMPS noise getting through to the signal cable from the supply lines, or directly onto the Live and Neutral from the switching oscillator.

Figure 2.14 shows a typical product with a switched mode supply that gives an idea of the various paths these emissions can take. Differential mode current IDM generated at the input of the switching supply is measured as an interference voltage across the load impendence of each with respect to earth at the measurement point. Higher frequency switching noise components VNsupply are coupled through CC, the coupling capacitance between primary and secondary of the isolating transformer, to appear between L/N and E on the mains cable, and CS to appear with respect to the ground plane. Circuit ground noise (digital noise and clock harmonics) is referenced to ground by CS and coupled out via signal cables as ICMsig (current through the signal cable) or via the safety earth as ICME.

The problem in real situation is that all these mechanism are operating simultaneously, and the stray capacitances CS are widely distributed and unpredictable, depending heavily on proximity to other objects if the case is unscreened. A partially screened enclosure may actually worsen the coupling because of its higher capacitance to the environment.

Coupling Paths for conducted emissions

2.11 Susceptibility to radiated field coupling

Coupling can take place either directly with the internal circuitry and wiring in differential mode or with the cables to induce a common mode current as shown in Figure 2.15. Since wiring lengths of a few inches approach resonance at these frequencies, coupling with internal wiring and PCB tracks is most efficient at frequencies above a few hundred MHz.

Susceptibility to radiated field coupling

2.12 Transient sources

Transients and spikes are different from continuously generated EMI. The below are the likely sources:

- Electro static discharge (ESD)

- Lightning

- Switching

- Power

2.12.1 Transients – Lightning, Switching and ESD

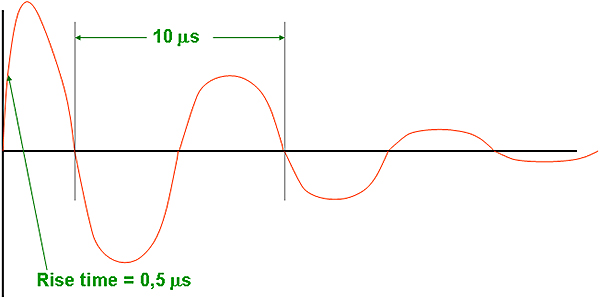

Virtually all the transient waveforms can be classified as shown in Figure 2.16.

Transients – lightning, switching and ESD

There is some variation in from where the second time period, i.e., T2 start. In Figure 2.16 it is shown as being from almost the start of the rise of the wave. However, in most cases, both of these times are specified as being ±30%.

2.12.2 Transient frequency

The Figure 2.17 shows the result of a study carried out on the mains supply and the telecom lines to record the number of amplitudes of the transient voltages. These figures obviously depend on the lightning strike density in the various parts of the world, and the degree of heavy load switching in the vicinity of the particular site. Particularly with lightning (but also with switching surges) the mains connection density plays a part.

Transient frequency

2.12.3 Electro static discharge (ESD)

The likely coupling paths are as follows:

- Stray capacitance

- Case bonding

- Track or wiring inductance due to magnetic fields generated in the discharge

2.13 Automotive transients

Fast transients can be coupled (usually capacitively) onto signal cables in common mode, especially if the cable passes close to or is routed alongside an impulsive interference source. Although such transients are generally lower in amplitude as compared to the mains-borne ones, they are coupled directly into the I/O ports of the circuit and will therefore flow in the circuit ground traces, unless the cable is properly screened and terminated or the interface is properly filtered.

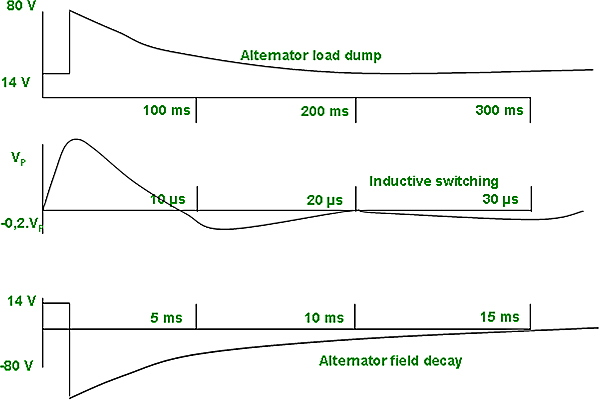

Other sources of conducted transients are the automotive 12 V supply. The automotive environment regularly experiences transients that are many times nominal supply range. The most serious automotive transients as shown in Figure 2.18 are as follows:

- The load dump that occurs when the alternator load is suddenly disconnected during heavy charging

- Switching of inductive loads such as motors and solenoids, and

- Alternator field decay that generates a negative voltage spike when the ignition switch is turned OFF.

Automotive transients

2.14 Supply voltage phenomenon

The supply voltage can exhibit a variety of disturbances as shown in Figure 2.19.

Supply voltage phenomenon

The ITIC (Information Technology Industries Council) curve shown in Figure 2.20, demonstrates the fluctuation levels and time periods that are likely to upset a PC. From this it is obvious that short-duration voltage variations can definitely affect electronic equipment.

It is just as necessary to ensure that mains-powered equipment doesn’t introduce any of these mentioned phenomena:

- Voltage dips (short-duration reductions in voltage)

- Interruptions (complete absence of power for longer than 3 seconds)

- Harmonics

- Unbalance (voltage differences between phases)

- Flicker (rapid voltage variations which are annoying as they affect incandescent lighting)

- Transients

ITIC Curve

3.1 Introduction

One of the most important aspects in EMC is to understand the difference between the possible modes of coupling. The basis of this differentiation is the idea that two separate circuit paths can coexist in the same set of conductors. The two coupling modes are as mentioned below:

Differential mode – differential simply means the difference between things of the same kind. Differential mode is the normal voltage and current between the signal and its return lines (or for that matter, it can be the positive and negative points in a circuit). Differential (in this case) means the difference between the two lines.

Common mode – common mode comes into the picture when there is another ground (reference) plane with respect to which voltages can exist and currents can flow. Common (here) means common between the two lines and a reference common to them. In common mode the two lines are seen as one.

EMI reduction has a lot to do with solving common mode problems. Common mode paths and voltages are more difficult to understand and visualize in comparison to differential mode. The latter involves current flowing as a normal circuit operation i.e., in loop. However, Common mode does not involve current flowing as per normal circuit operation as it involves multiple coupling paths and parasitic elements.

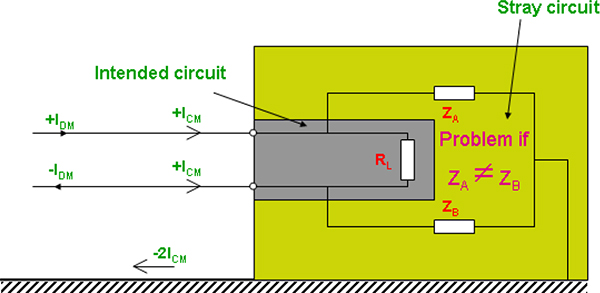

3.2 DM/CM conversion

Although it is said that common mode currents might be unrelated to the intended signal currents, there may also be a component of common mode current that is due to the signal current. Conversion occurs when the two signal conductors present different impedances to their environment, which is represented by the external ground. These impedances are dominated at RF by stray inductance and capacitance that relate to physical layout and are only under the circuit designer’s control (if and only if that person is also responsible for physical layout).

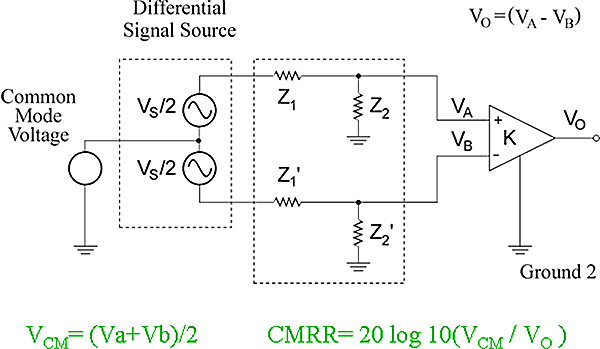

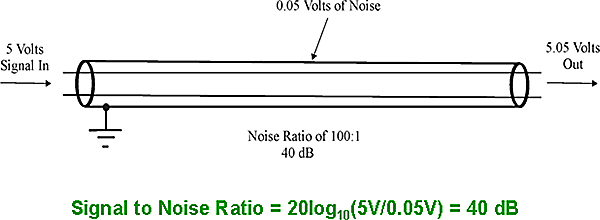

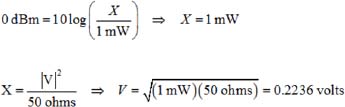

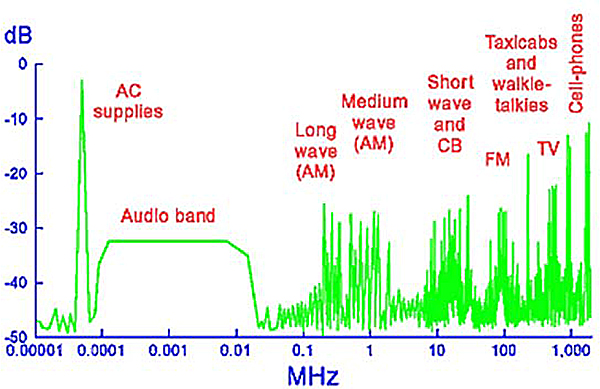

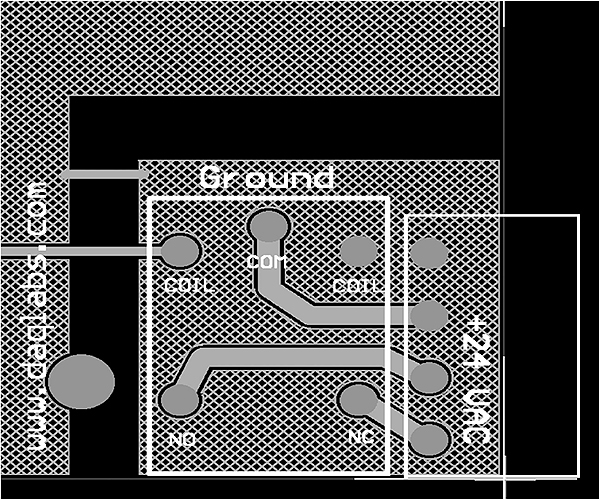

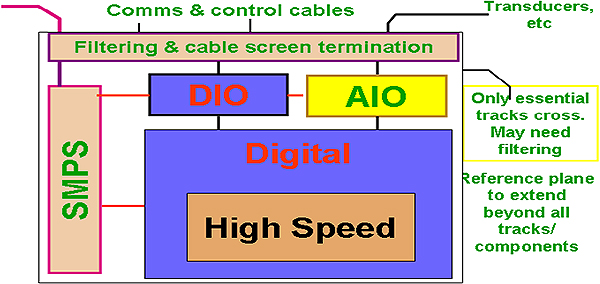

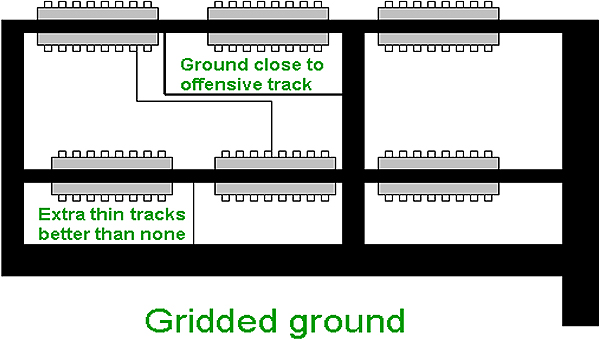

In Figure 3.1 the differential mode current IDM produces the desired signal voltage across load RL. The common mode current ICM does not flow through load RL directly but through impedances ZA and ZB, and returns back through the external ground. ZA and ZB are not circuit components but distributed stray impedances (typically but not always capacitive) and are determined by factors such as the surface area of PCB tracks and components and their proximity to chassis metalwork and other parts of the equipment. If ZA = ZB then no voltage is developed across RL by the common mode currents ICM. But any inequality (i.e., ZA ≠ ZB) results in such a voltage, proportional to the differences in impedance as given by equation 1: