52896WA Advanced Diploma of Civil and Structural Engineering (Materials Testing)

Investigation of the properties of construction materials, the principles which…Read moreGraduate Diploma of Engineering (Safety, Risk and Reliability)

The Graduate Diploma of Engineering (Safety, Risk and Reliability) program…Read moreProfessional Certificate of Competency in Fundamentals of Electric Vehicles

Learn the fundamentals of building an electric vehicle, the components…Read moreProfessional Certificate of Competency in 5G Technology and Services

Learn 5G network applications and uses, network overview and new…Read moreProfessional Certificate of Competency in Clean Fuel Technology - Ultra Low Sulphur Fuels

Learn the fundamentals of Clean Fuel Technology - Ultra Low…Read moreProfessional Certificate of Competency in Battery Energy Storage and Applications

Through a scientific and practical approach, the Battery Energy Storage…Read more52910WA Graduate Certificate in Hydrogen Engineering and Management

Hydrogen has become a significant player in energy production and…Read moreProfessional Certificate of Competency in Hydrogen Powered Vehicles

This course is designed for engineers and professionals who are…Read more

This manual will give you a solid understanding in electronic terminology and symbols, as well as the construction and operation of common electronic components and the testing and repairing of printed circuit boards.

Revision 5

Website: www.idc-online.com

E-mail: idc@idc-online.com

IDC Technologies Pty Ltd

PO Box 1093, West Perth, Western Australia 6872

Offices in Australia, New Zealand, Singapore, United Kingdom, Ireland, Malaysia, Poland, United States of America, Canada, South Africa and India

Copyright © IDC Technologies 2011.

All rights reserved.

First published 2009.

All rights to this publication, associated software and workshop are reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means electronic, mechanical, photocopying, recording or otherwise without the prior written permission of the publisher. All enquiries should be made to the publisher at the address above.

Disclaimer

Whilst all reasonable care has been taken to ensure that the descriptions, opinions, programs, listings, software and diagrams are accurate and workable, IDC Technologies do not accept any legal responsibility or liability to any person, organization or other entity for any direct loss, consequential loss or damage, however caused, that may be suffered as a result of the use of this publication or the associated workshop and software.

In case of any uncertainty, we recommend that you contact IDC Technologies for clarification or assistance.

Trademarks

All logos and trademarks belong to, and are copyrighted to, their companies respectively.

Acknowledgements

IDC Technologies expresses its sincere thanks to all those engineers and technicians on our training workshops who freely made available their expertise in preparing this manual.

Contents

1 Introduction to Troubleshooting 1

1.1 Troubleshooting Basics 1

1.2 Common Troubleshooting Techniques 5

1.3 Gaining Circuit Familiarity 8

1.4 Getting Prepared for Troubleshooting 20

1.5 Summary 21

2 Failure Analysis and Prevention in Electronic Circuits 23

2.1 Failure Symptoms 23

2.2 Failure Causes 25

2.3 Failure Types 26

2.4 Some Useful Terms in Failure 28

2.5 Summary 29

3 Device Troubleshooting – I 31

3.1 Tools for Servicing 31

3.2 Test and Measuring Instruments 36

3.3 Safety Issues – Test and Tagging of Portable Electrical Equipment 54

3.4 Summary 55

4 Device Troubleshooting – II 57

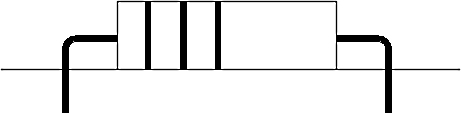

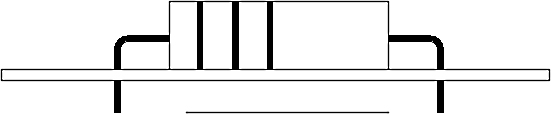

4.1 Testing of Passive Components 57

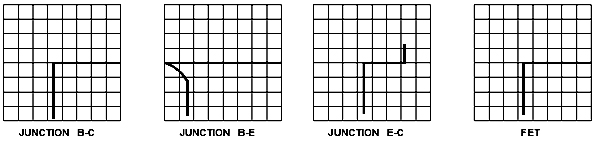

4.2 Testing of Semiconductor Devices 62

4.3 Testing Bipolar Transistors 63

4.4 Testing Other Active Components 65

4.5 Testing Diodes, Transistors and In-circuit Semiconductors Using Oscilloscopes 78

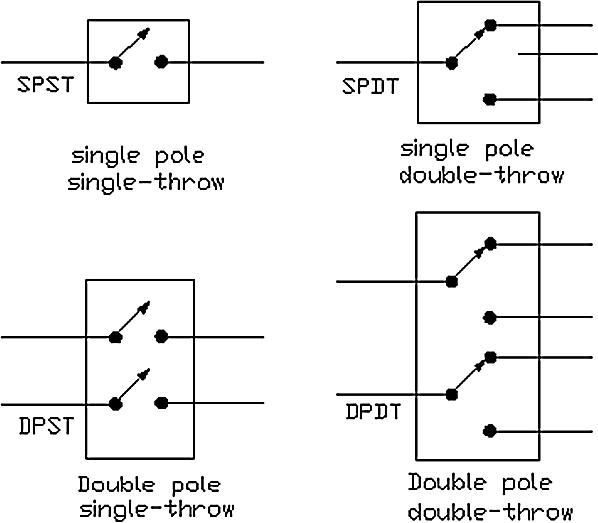

4.6 Switches 80

4.7 Safety Issues for Plugs, Sockets and Portable Appliances 82

4.8 Summary 83

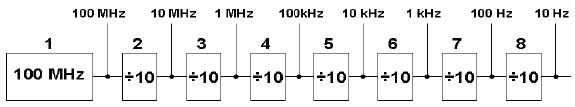

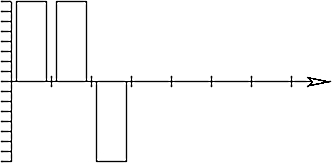

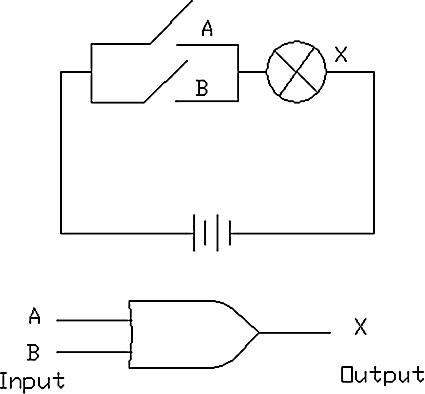

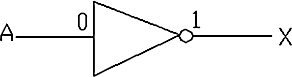

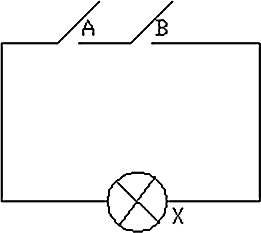

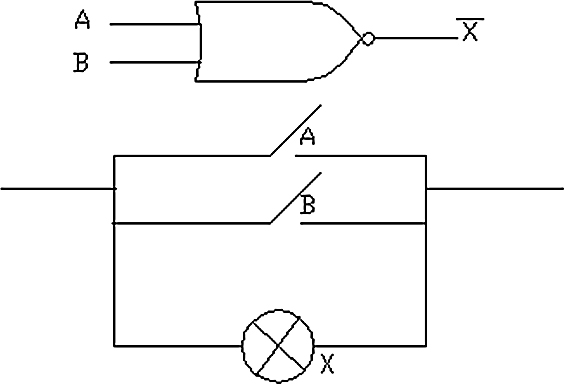

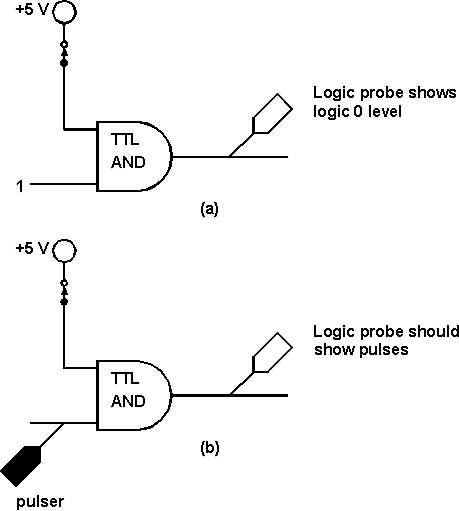

5 Troubleshooting Digital Systems 85

5.1 Moving from Analog to Digital 85

5.2 Moving into the Digital Circuits 87

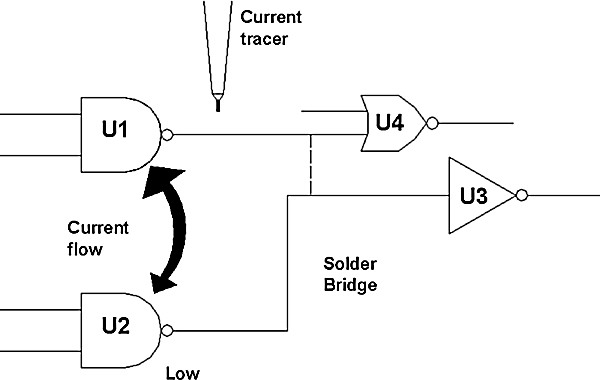

5.3 Typical Faults in Digital Systems 97

5.4 Digital Circuit Troubleshooters 99

5.5 Digital Integrated Circuits 106

5.6 Programmable Logic Device (PLD) and Memory Definitions 108

5.7 Practical Tips 112

5.8 Precautions 112

5.9 Summary 112

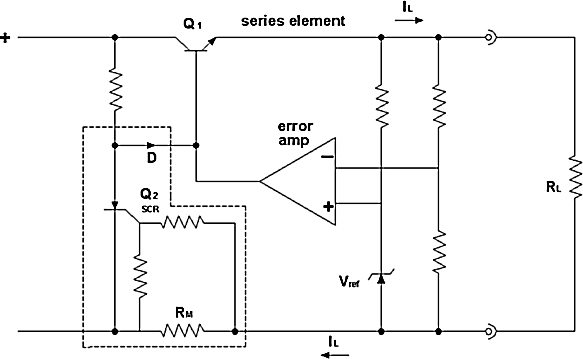

6 Power Supply and Subsystems Troubleshooting 115

6.1 Power Supply 115

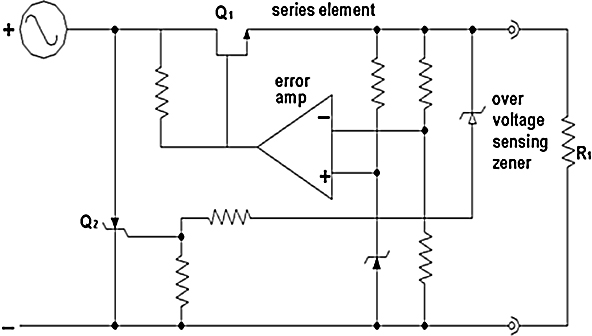

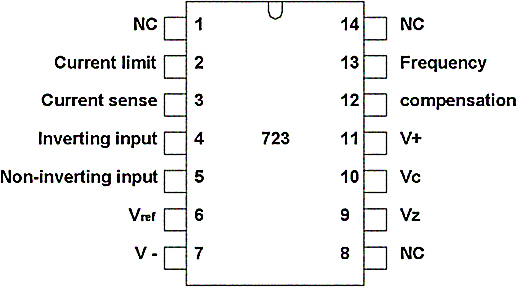

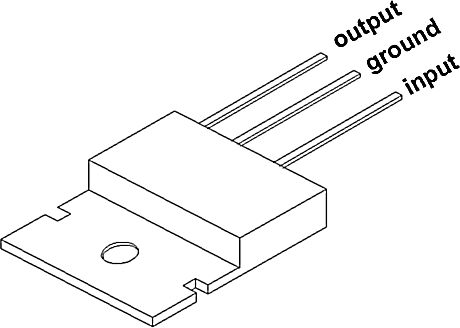

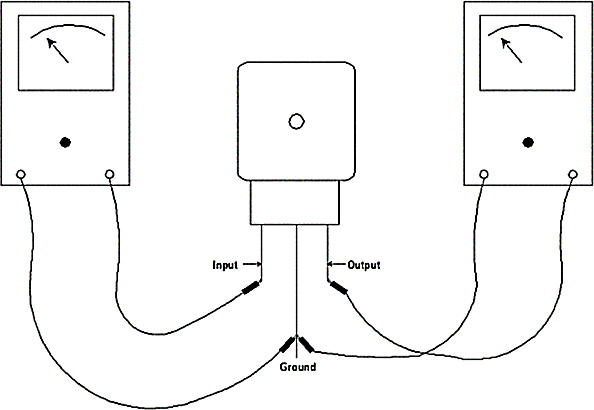

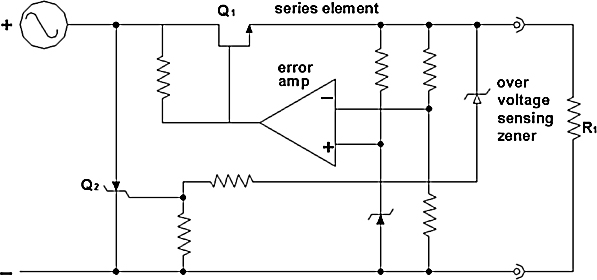

6.2 Regulators 119

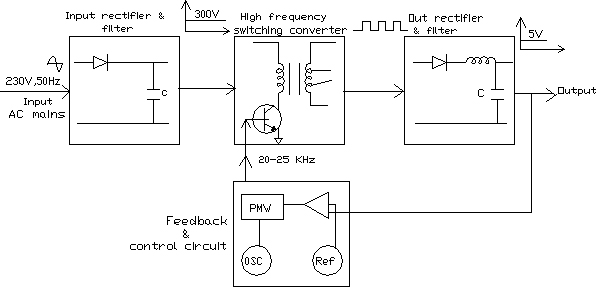

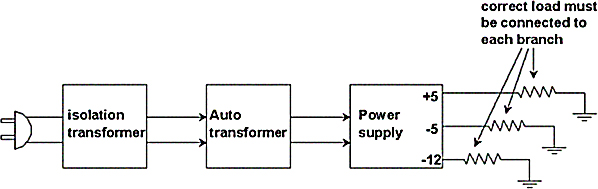

6.3 Switched Mode Power Supplies (SMPS) 123

6.4 Oscillators 125

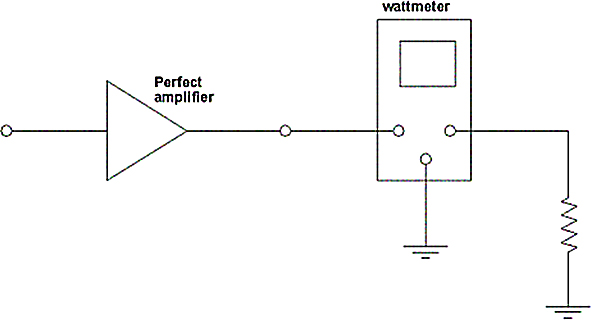

6.5 Amplifiers 129

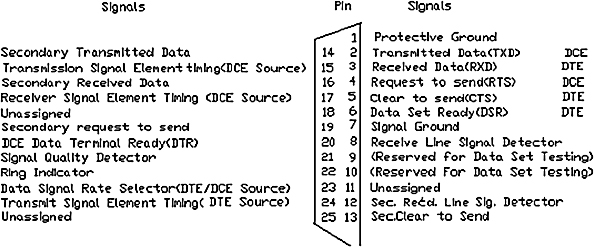

6.6 Troubleshooting of RS-232 Serial Data Standard 131

6.7 Troubleshooting Microprocessor Based Systems 134

6.8 Summary 138

7 Temperature as a Parameter for Testing, Signal Injection and Signal Tracing 139

7.1 Effect of Temperature on Electronic Circuits 139

7.2 Testing 142

7.3 Actual Troubleshooting 143

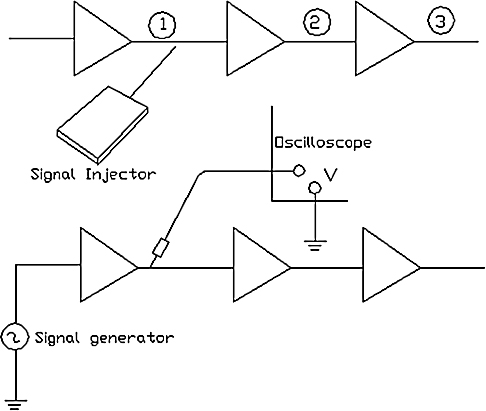

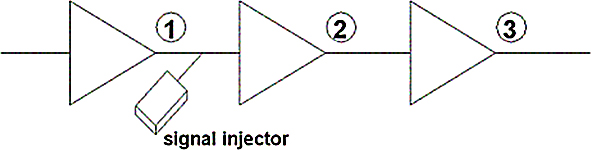

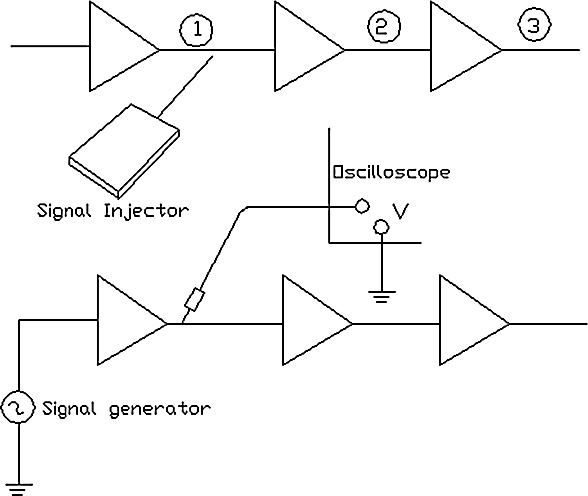

7.4 Signal Injection 144

7.5 Signal Tracing 147

7.6 Summary 149

8 Phenomenal Troubleshooting 151

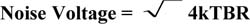

8.1 Noise 151

8.2 Intermittent 158

8.3 Sources of Interference 159

8.4 Static Discharge 160

8.5 EMI/EMC and its Sources 160

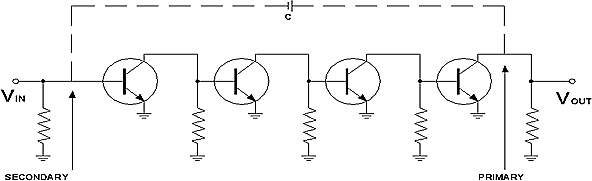

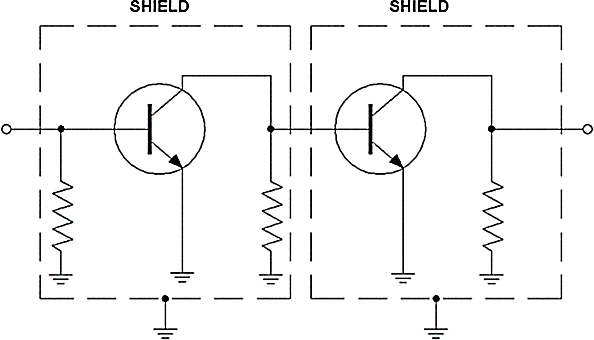

8.6 Cross-Talk 164

8.7 Summary 167

9 PCB Testing and Soldering Techniques 169

9.1 What is soldering? 169

9.2 Process of Soldering 170

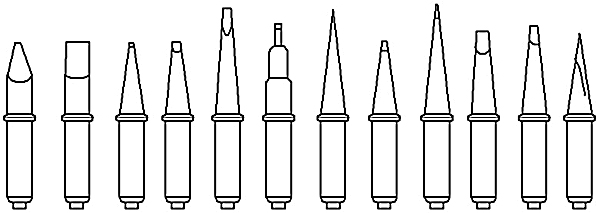

9.3 Soldering Tools 171

9.4 Solder and Flux 175

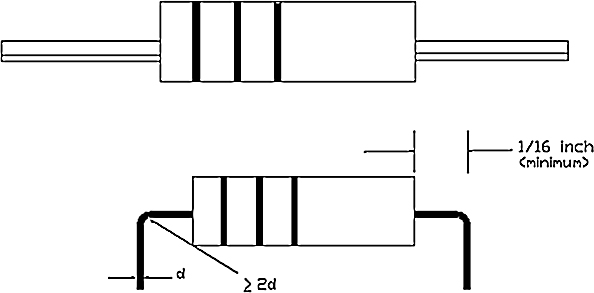

9.5 Component Forming 176

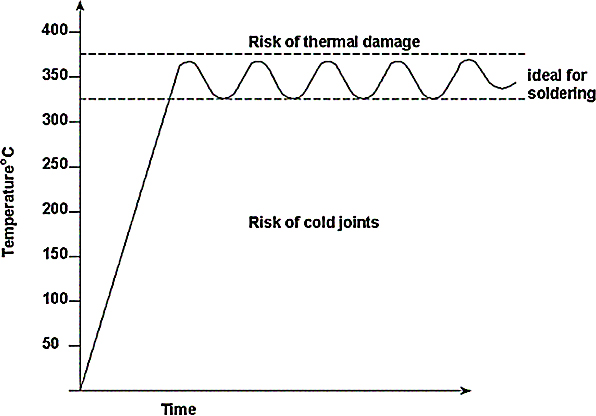

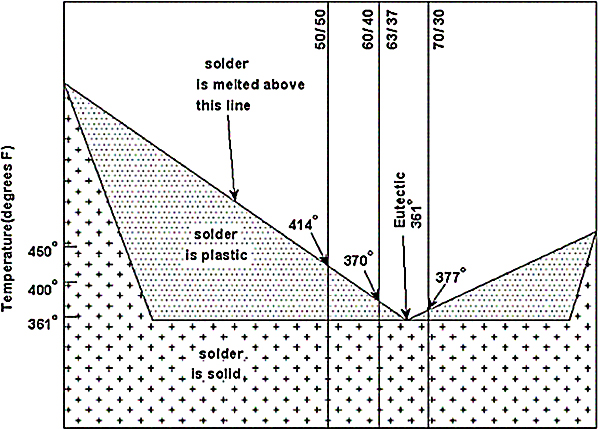

9.6 Temperature Range in Soldering 177

9.7 Component Replacement 178

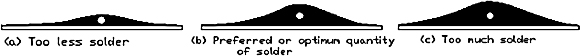

9.8 Inspecting Solder Joint 179

9.9 Unsoldering Connections 180

9.10 Additional Soldering Tips 183

9.11 Additional De-soldering Tips 183

9.12 First Aid Steps 184

9.13 Printed Circuit Board 184

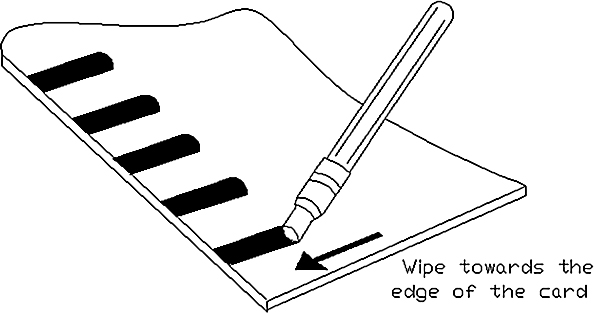

9.14 Troubleshooting of Surface Mounted PCBs 189

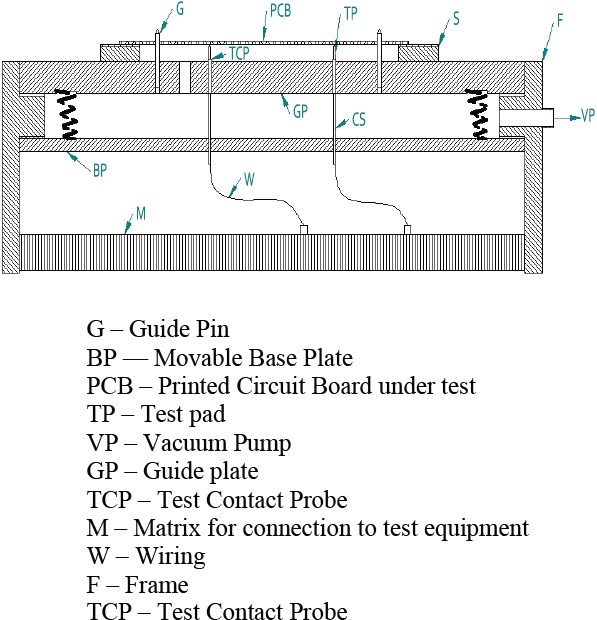

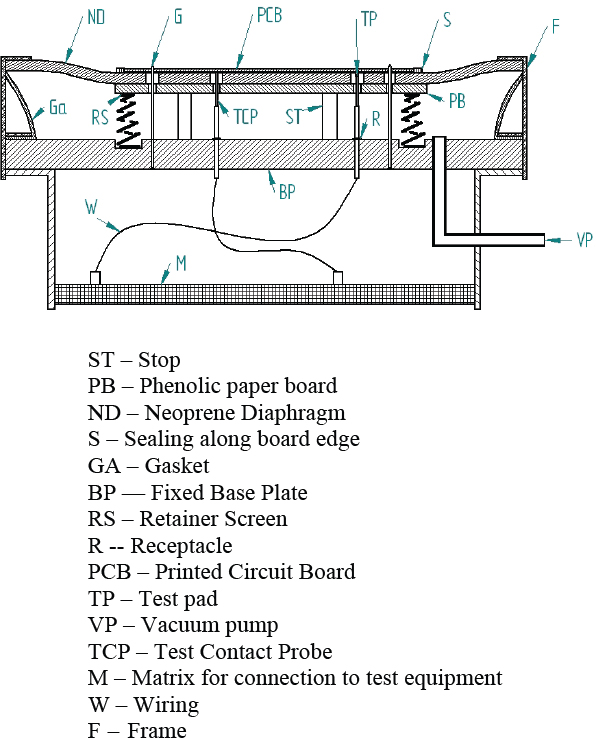

9.15 Testing and Troubleshooting with ATE 191

9.16 Summary 198

10 Maintenance and Safety Aspects 201

10.1 Do we need Maintenance? 201

10.2 Types of Maintenance 202

10.3 Aims of Maintenance 204

10.4 Advantages of Preventive Maintenance 204

10.5 Importance of Sound Maintenance Management 204

10.6 Maintenance Policy 205

10.7 Maintenance Organization 206

10.8 Maintenance Manuals 207

10.9 Safety Aspects 207

10.10 Summary 211

Appendix A – Question and Answers 213

Appendix B – Questions and Answers 241

Appendix C – Troubleshooting of Variable Regulated Power Supply 269

Electronic equipment can develop a wide variety of problems. The act of troubleshooting arises in order to make the problems disappear so that the equipment works as per the expectation. This introductory chapter provides an overview of troubleshooting processes and various troubleshooting techniques. It also emphasizes how to prepare and read a circuit diagram, as a first step for troubleshooting.

Learning objectives

- Understand how to prepare a circuit diagram

- Study of electronic equipment in brief

- Study the basic concepts of troubleshooting

- Understand the process of troubleshooting

- Study the techniques used in troubleshooting

- Understand how to start troubleshooting

- Know preliminary precautions

1.1 Troubleshooting Basics

In general, for any application, equipment is designed and manufactured to work trouble free within its specified limits during its useful time. However, sometimes there is a conflict between the expectations of the user and the performance of the instrument. Thus develops the need for troubleshooting and maintenance.

What is Troubleshooting?

Troubleshooting is the process of isolating and correcting a problem in malfunctioning equipment so that it returns to its expected performance level. The process of troubleshooting requires a systematic fault finding approach. Whenever a fault occurs, two things can happen:

- The equipment does not work at all

- The equipment works abnormally

The second type of fault can be further sub-divided into:

- Constant error or malfunctioning (exceeding absolute maximum rating)

- Intermittent errors (external noise pick-up, heat, shock, increase in humidity, etc.)

The basics which can be applied to troubleshooting are given below:

- Look for obvious possibilities. If there are no obvious faults, measure the power supply voltage. If it is not the correct value, don’t go any further until you find out why.

- Use symptoms whenever possible to zero in on the section at fault. If the symptoms do not get you to the trouble region, use a signal tracing or signal injection method. These methods are discussed in an upcoming chapter.

- Once you have zeroed in the on the troubled circuits, locate the defective component. Tough problems like closed loops, distortion, noise and intermittent, require special troubleshooting techniques.

- Make efficient use of the troubleshooting and test equipments. Specialized equipment that you build yourself can also be very useful.

- Digital and microprocessor circuits require special equipment and a few special techniques.

- When looking for faulty components, troubleshooting should involve the following steps:

- Make a measurement

- Compare the measured value with what you are supposed to get

- If the measured values do not match what you are supposed to get, find out why

- When you have located the defective component, replace the component professionally. For surface mount components, some newer techniques are required.

- You should be well informed with the operation of testing and troubleshooting equipment. The selection of test equipment depends on the amount of service and the type of service. Some of the popular test equipment are:

- Analog VOM

- Digital VOM

- Oscilloscope

- Logic Probe

- Logic Pulser

- Sine-wave generator

- Regulated DC power supplies

- Transistor testers

- Finally make sure that your work indicates high quality professional servicing. Experienced technicians often use a type of statistical approach for troubleshooting. For example, if there is some distortion in sound in a speaker, there can be several possible faults for the symptom. From experience the technician knows that a battery will fail more often than a transistor. So the battery would be checked and replaced first.

- It is usually easier to replace a battery than a transistor; ease of replacement is also a factor.

The following table shows a list of component failure in their order of probable occurrence:

Order of occurrence of component failure

| Order of occurrence of failure | Component |

| 1 | Mechanical and electromechanical devices such as relays, switches, plugs and sockets. |

| 2 | Components that get hot in their normal operation, like power amplifiers and rectifiers. |

| 3 | Electrolytic capacitors of small versions and those subjected to high voltage. |

| 4 | Active devices like transistors and SCRs. |

| 5 | Passive devices like resistors and capacitors. |

- As said earlier it is best to measure the power supply voltage first, when beginning troubleshooting. If the power supply voltage is not the correct value, nothing will work well in the circuit.

- A low power supply can cause failure to the circuit, which is not located anywhere near the supply. It is best to measure the power supply voltage while it is delivering current to the system. In battery operated equipment, the system should be energized when the battery voltage is being measured.

- An incorrect power supply voltage can damage a digital system. If a wrong power supply voltage is measured in a digital circuit, shut it down immediately. Then use your bench supply to energize the circuit and look for possible damage caused by the incorrect voltage.

- While measuring the power supply voltage with an analog meter, if you are not sure what value of voltage (or current) you are going to be measuring, then you have to start with the highest scale and work down.

The Troubleshooting Process

The process of troubleshooting comprises the following steps:

- Fault Establishment

- Fault Location

- Fault Correction

Let’s address these steps in brief:

Fault Establishment

It is important to establish the presence of a fault in equipment before taking any other action. In some cases a system may be reported faulty, but it could be a case of faulty operation or a system failure may be reported with either very little or misleading information. It is essential that a functional test, checking the system’s actual performance against its specification must be made and all fault systems must be noted.

It is also important to check the history of the equipment and repair and servicing work carried out earlier by any other person.

Fault Location

This involves pin-pointing the cause of the fault by studying the literature relevant to servicing, maintenance and repairs. The fault is located first in subsystem and then in a single component in the sub system.

Fault Correction

Fault correction consists in replacing or repairing the faulty component. This is followed by a thorough functional check on the whole system.

Troubleshooting Aids

Troubleshooting aids help in quickly analyzing a malfunction and taking corrective action. The following points are discussed in this aspect:

Tools

A basic set of tools and test equipment like multimeter and oscilloscopes are necessary. Sometimes specialized equipment are required, such as a high speed scope. The maintenance technician is required to have all this knowledge.

Documents

A complete set of documentation is a must. Most manufacturers supply the following documents with their manuals:

- Schematic document

- Circuit board illustration

- Circuit board location

- Power distribution diagram

- Circuit board interconnection diagram

- Fault tracing flowchart

- Diagnostic software

- List of replaceable parts

- List of special tools for servicing

Data Manuals

A good list of data manuals is essential. There are data books from all major component manufacturers which can be collected.

Thumb Rule in Troubleshooting:

- If the equipment is totally dead, then the problems are generally related to the malfunctioning of the power supply.

- If the equipment starts malfunctioning when it warms up, it can be due to the dryness of electrolytic capacitors. In this case they should be tested.

- The problems which come and go suddenly, intermittent problems are often due to bad connections. The reason for this can be a cold solder joint of internal or external connectors that need to be cleaned.

- Failures because of burnt, melting of the leads of components, cracking of the components and so on are identified by visual inspection and burnt smell.

1.2 Common Troubleshooting Techniques

The various troubleshooting techniques given below are used in the majority of electronic systems. The type of system being handled will decide which technique should be adopted.

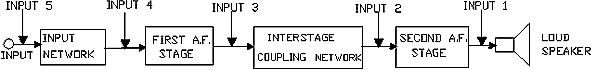

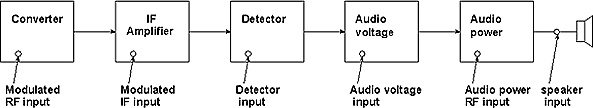

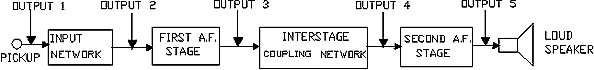

Functional Area Approach

An electronic system comprises several functional parts such as power supplies, amplifier, signal converters, etc. When the system fails to give the expected performance, the problem could be in any of these functional areas. Therefore, it is essential to troubleshoot the system in order to isolate the fault to the failing functional area and then to the failing component. The logical approach of isolating a fault is through a process of elimination of the functional areas that are performing properly. Once a failure is isolated, further analysis of the circuitry within this area is carried out to isolate the malfunction to the faulty component. This functional area approach is also called the Block-Diagram approach to troubleshooting.

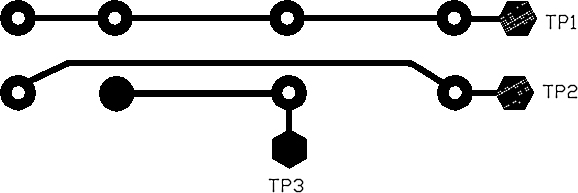

Split Half Method

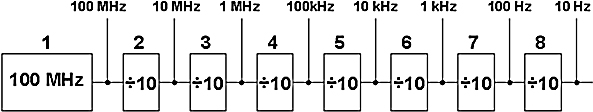

In this technique, as the name suggests, the circuit is split in half and the output is checked at the half-way point in case of an absence of an output. This helps to isolate the failing circuit in the first or second part. When the faulty half is determined, the ageing circuit is split into half for further isolation of failure. This splitting is continued until the failure is isolated to one function or component.

The Half-split method is extremely useful when the system is made up of a large number of blocks in the series:

Split Half Method

Many electronic systems do not involve only series connected blocks. They may have feedback loops or parallel branches in a part of the circuit. Hence use of this method is rather restricted.

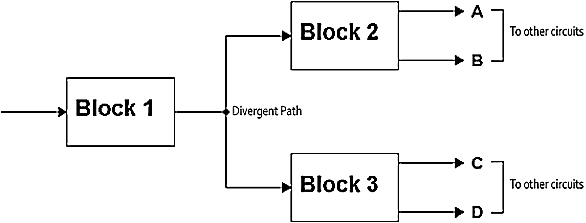

Divergent Path

Here the output from one block is fed to two or more blocks. In such systems, it is best to start by checking the common feed point. Alternatively if output is normal (at A or B in fig. 1.3), check after the divergence point. Conversely, if one output is abnormal, check before the common point. The most common example is that of the power supply circuit which supplies dc power to various subsystems in equipment.

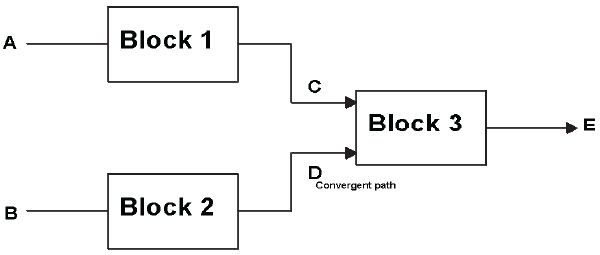

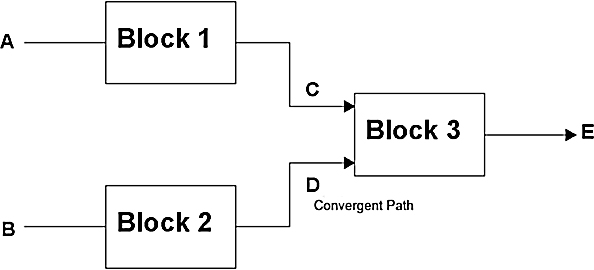

Convergent Path

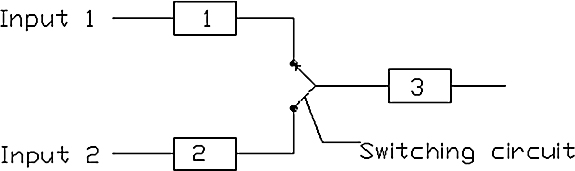

In a convergent path two or more input lines feed a circuit block:

Convergent Path

In order to check such a scheme, all inputs at or before the point of convergence must be checked one by one. If any of the inputs is incorrect (at C or D in fig. 1.4), then the fault lies in that particular input circuit. If all are found to be correct, the fault lies beyond the convergent point. For example, if C and D are correct and there is no output at E, the fault lies in unit 3. But if input at C is faulty, the fault lies in block 1 or before that.

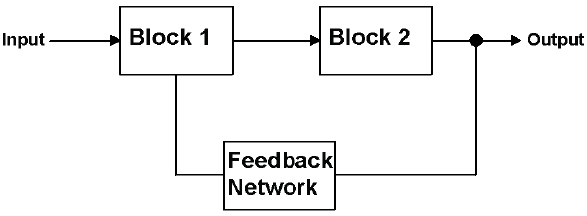

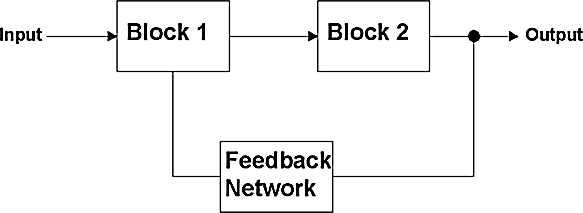

Feedback Path

The feedback loop usually corrects the output of some block with the input of an earlier block via some network called feedback network. Since the circuit behaves as a closed loop, any fault within the loop will appear as if all the output blocks within the system are at fault:

Feedback Path`

Before starting the troubleshooting of a system having feedback loop, the type of the feedback and its use should be well understood. Feedback paths are basically provided for the following functions:

- To modify circuit function —- Feedback loop is provided to modify the characteristics of the system. For example, automatic gains control system in a radio receiver.

- To sustain circuit function —- Feedback is totally essential for an output to exist. For example, an Oscillator circuit.

Having identified the type of feedback circuit, one can proceed as follows regarding locating the fault.

For the first type, i.e. modifying feedback, it may be possible to break the feedback loop and convert the system to a straight linear data flow. Each block can then be tested separately without the fault signal to be fed around the loop. In some cases instead of completely breaking the loop, the feedback can be modified at or near the point where it rejoins the main forward path. If the output appears normal, check the feedback path, otherwise, check the forward path.

For the second type, i.e. sustaining type, feedback is disconnected from the output and a suitable test signal is injected to check the performance of various circuit blocks.

Fault Location in Switching Path (rsk40)

If a system has switch-able parts and if the circuit function is found faulty in one position of the switch then throw the switch to another position. If the problem persists, check the switch in common circuitry. If the problem disappears with this action, check that the circuitry switched out.

1.3 Gaining Circuit Familiarity

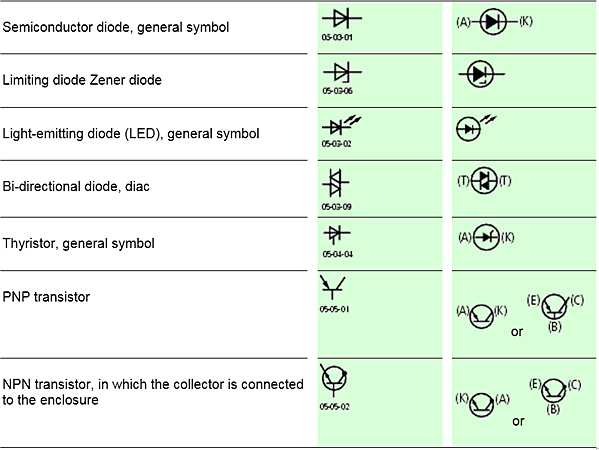

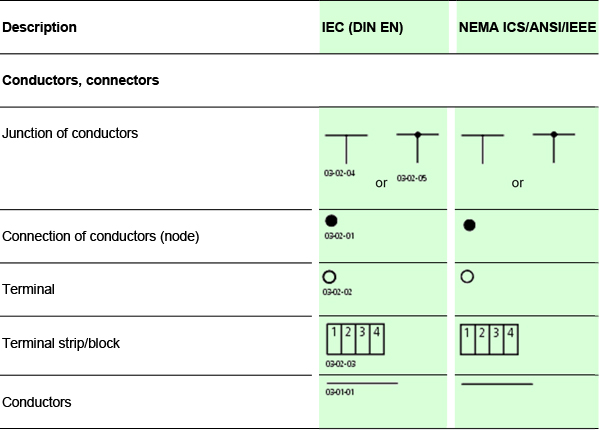

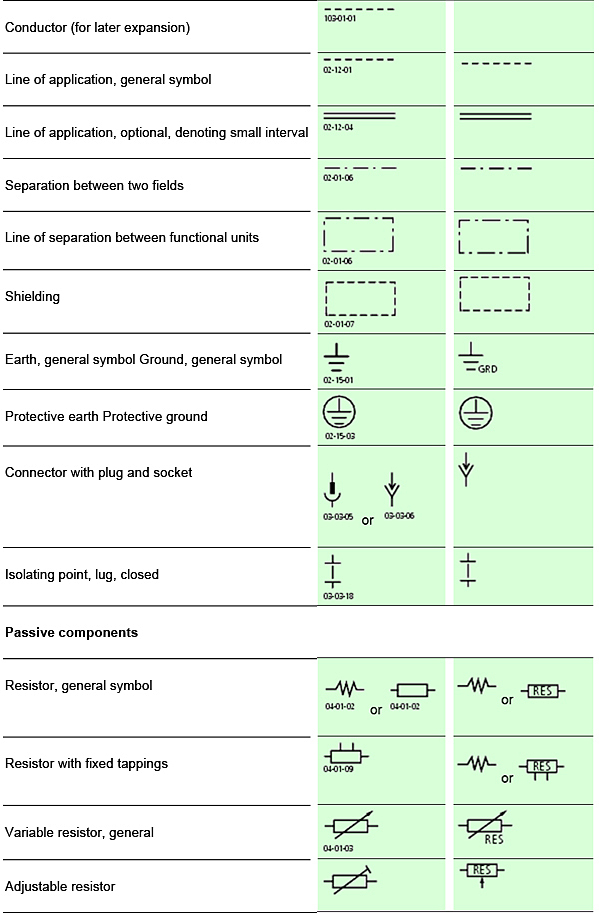

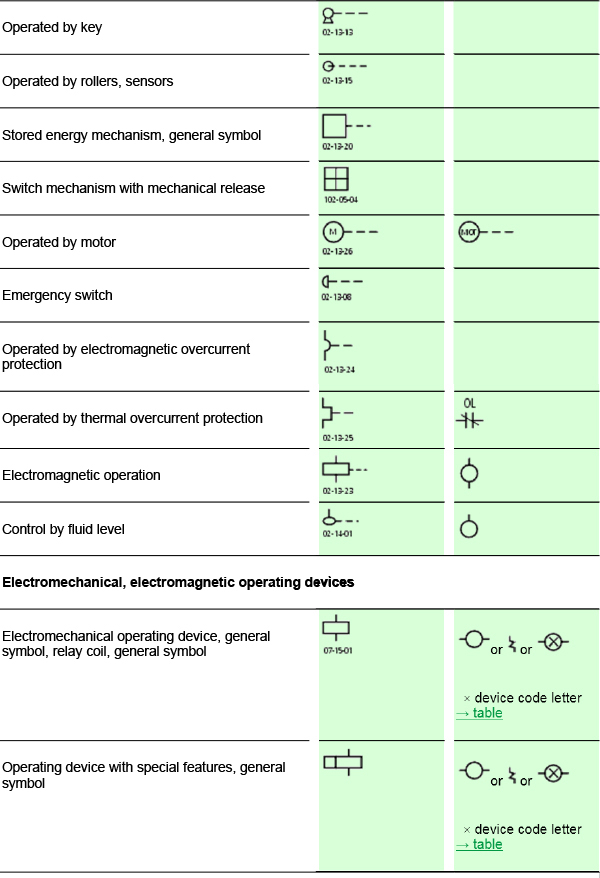

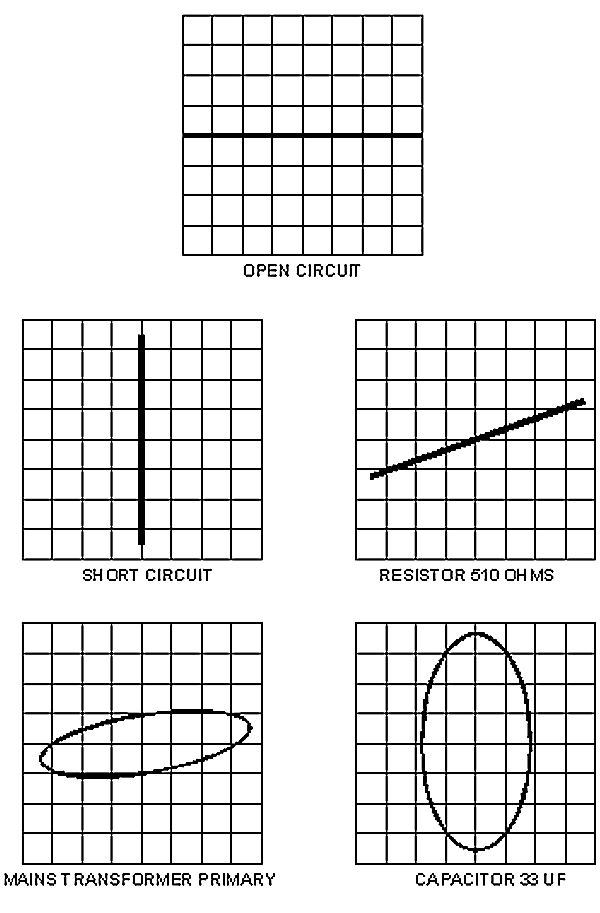

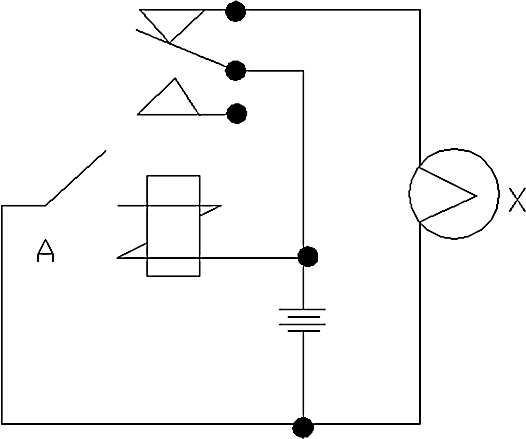

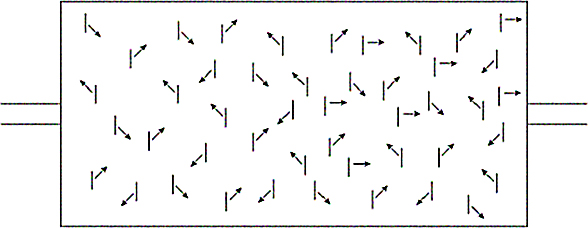

A circuit diagram is a graphical representation of the interconnections of various components constituting the equipment. It is the most important document for the maintenance technician. Usually every assembly in electronic equipment is assigned an assembly number which appears on the circuit board and on the diagram. Commonly used symbols in electronic circuits are shown below in Figure 1.7.

The maintenance technician should be well versed with the circuit of the system before actually starting troubleshooting. A circuit diagram is the most important document for the technician. Many-a-time the circuit diagram of the system or equipment is not ready or not provided by the manufacturer. In that case, the technician has to prepare the circuit diagram. The circuit diagram makes the fault finding process easy.

Preparing a Circuit Diagram

The technician should be experienced enough to draw a circuit diagram. Usually, it is not recommended for larger systems. A larger system is broken into parts (subsystems) and then circuit diagrams for the smaller, suspected systems is drawn to trace the fault. The following points must be noted when preparing a circuit diagram:

- After identifying what is the type of fault, the very first thing to be done is to understand the functionality of the system. Split the system into a few functional blocks, which will make a functional working diagram.

- The components and their types are identified. The specifications of the components are notes taken from the manual or data book given with the equipment.

- Make a note of the interconnections of various subassemblies like power supply, PCB assembly, front panel, etc.

- The printed circuit board is removed. Usually individual boards can be removed in industrial systems as they are of modular construction for easy maintenance.

- First locate the components on the paper. Understand the PCB pattern. Place the PCB in front of strong light so that the PCB interconnections are clearly visible. If you look at the back of the PCB, then what you see is the mirror image of the connections as seen from the front. Now, make a sketch of the components and PCB pattern.

- Clearly differentiate between input and output. Start with the supply rail, not the common. Now draw the components connected to the supply lead. The ground or common lead will be easy to identify.

- Use your knowledge of the functional aspects of the equipment to draw out the stages. Power transistors will be either with the power supply circuit or in the output stage. If one stage gets a bit complicated try starting from another stage like input or output stages following the signal path.

- Now redraw the circuit in the conventional manner. After the initial attempt, the technician will be able to identify the nature of the circuit.

- Check if all the components on the card are in the sketch and check the polarities of the components.

- Always draw the sketch with pencil for easy correction.

Reading a Circuit Diagram

A circuit diagram is a graphical representation of interconnections of various components constituting the equipment. It is the most important document for the maintenance technician. Usually every assembly in electronic equipment is assigned an assembly number which appears on the circuit board and on the diagram. Commonly used symbols in electronic circuits are shown below:

Various Symbols in electronic circuits

Circuit symbols to DIN EN, NEMA ICS/ANSI/IEEE/CSA

(The following comparison of circuit symbols is based upon the following international/national specifications:

-IEC 60617 graphic symbol database (DIN EN 60617-2 to DIN EN 60617-12

-NEMA ICS 19-2002, ANSI Y32.2/IEEE 315/315 A, CSA Z99)

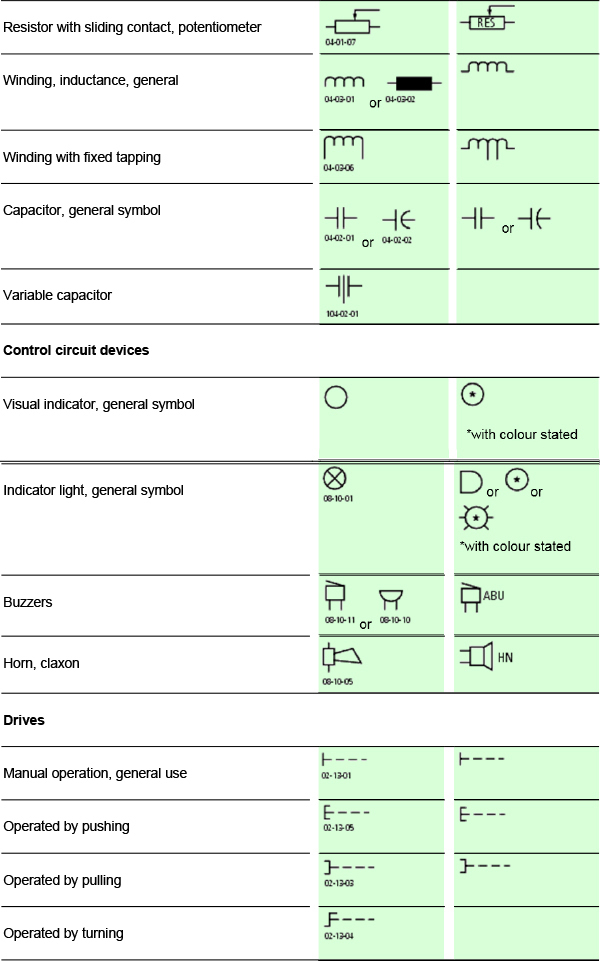

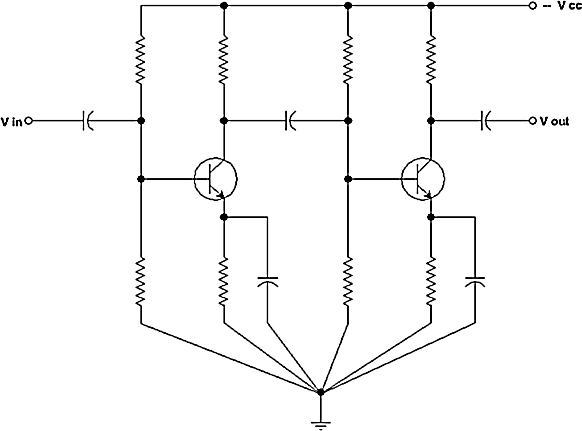

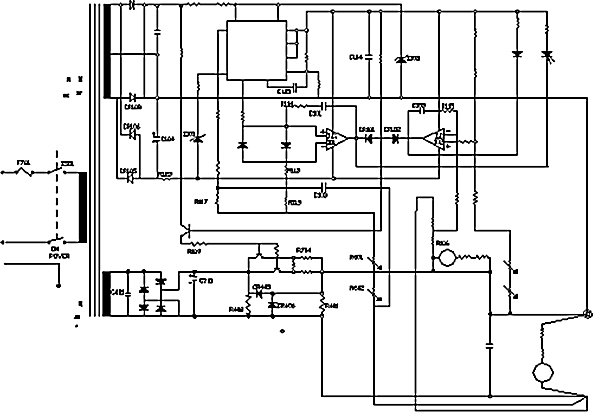

A circuit diagram illustrating some symbols is also shown below:

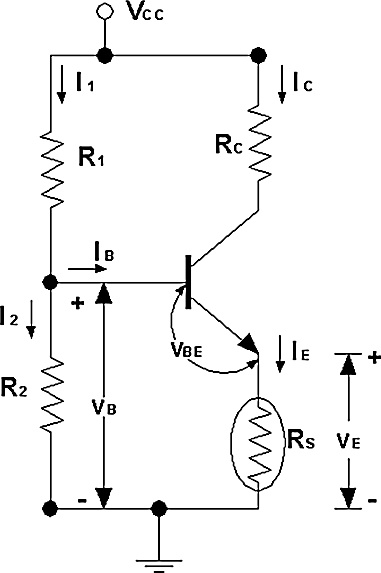

Electronic Circuit Diagram

The Making of an Electronic Circuit

An electronic circuit makes use of both active and passive components. These components are physically interconnected with each other to form any electronic circuit. There are three major techniques to interconnect the components. Let us have a brief overlook of these methods:

- Solder

- Wire-wrap

- Printed Circuit Board

Solder

This method makes use of a solder and a wire to interconnect electronic components. It is a very slow method and is very cumbersome if a large number of devices are to be connected.

Wire-wrap

This technique tightly winds a small gauge wire around a wire-wrap metal post or terminal. There are special wire-wrap metal post sockets for the ICs that have longer posts for wire-wrapping the wire. Also, special tools are needed for wrapping and un-wrapping the wire.

Printed Circuit Board (PCB)

This technique includes interconnections between points printed in metal on the non-conductive board. The circuit is printed on the board by a series of photographic and chemical procedures. Most of the equipment in practice make use of PCB. They are generally made for completely checked out and working boards, as it is difficult to make wiring changes on the PCB.

A Quick Glance at Electronic Equipment

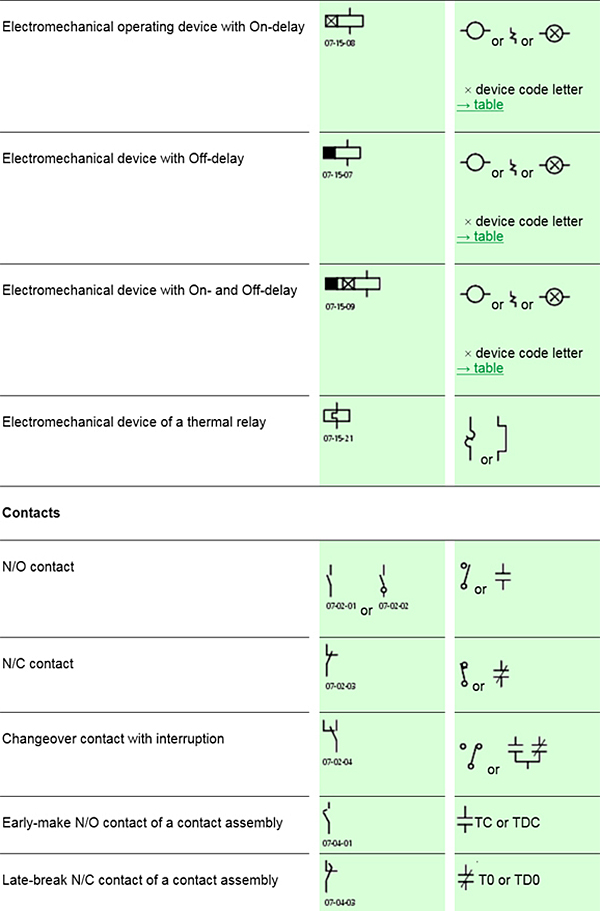

There can be one or more circuit boards inside of electronic equipment. They are mounted inside a wooden or metallic cabinet with some arrangement of interconnecting the circuit boards. This arrangement is called Edge Connectors.

The purpose of edge connectors is to bring signals and powers to and from the circuit boards without having to connect a wire to the circuit board itself. This arrangement provides easy installation and removal of the circuit board in equipment:

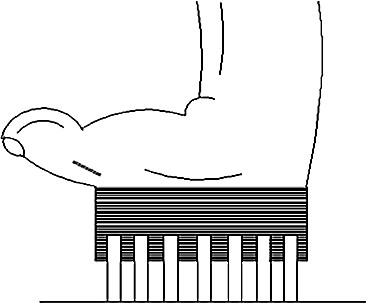

Electronic Equipment

Also inside of electronic equipment there is an assembly called card rack for the compact placement of the PCBs. But it is difficult to put a test probe on the circuit board for making any type of measurement or for troubleshooting. To eliminate this problem, special circuit boards called ‘extender cards’ are inserted into the card rack and the circuit board is extended into the extender card.

An extender card is just a wiring extension to make the circuit board accessible for testing.

Classification of System

In the literature, terms such as component, equipment or system have been used. The following table distinguishes between these terms:

Classification of System

| Serial Number | Nomenclature | Description | Example |

| 1 | System | Collection of equipment arranged to perform a function. | Television, Missile. |

| 2 | Equipment | Collection of components arranged to operate without the need for other components. | Radio Transmitter, the central part of a missile. |

| 3 | Assembly | Collection of components in a prescribed order not all of which have, as yet, been so arranged. | Terminal board with components parts attached. |

| 4 | Component | Collection of elements arranged in a prescribed order. | Resistor. |

| 5 | Element | A simple object which can not be further sub-divided. | Filament, a relay contact. |

1.4 Getting Prepared for Troubleshooting

Where do you start?

A close visual inspection is a good and quick start for troubleshooting. It gives a clue for problems such as burned spots and places where high voltage arc has occurred. A quick look to the circuit also gives an idea of the condition of fuses and circuit breakers.

The troubleshooting technician should collect the history of the system. He/she should know whether the problem had occurred before and what is the frequency of the occurrence of the problem.

On the basis of the knowledge of how the system works, the kind of failure can be detected. This would lead you to select the troubleshooting technique.

If the system is not producing the desired end result, look for what is doing it correctly. You can locate where the problem is not present so that you can then focus on another location for troubleshooting.

If the system has been having problems immediately after some kind of maintenance or other change, the problems could be linked to those changes.

After all, the choice of techniques and strategies for troubleshooting totally depends upon the technician. The following points would be helpful for effective troubleshooting:

- Familiarity with the equipment

- Analyzing possible causes of trouble

- Developing a general troubleshooting procedure

Preliminary Precautions

- Identify the mains power supply voltage and the maximum voltage that can be applied from the power source. The mains power supply voltage can be either 110 V, 60 Hz or 220 V, 50 Hz. Make sure that a protective ground connection by way of the grounding conductor is or is not provided.

- In order to avoid shock, the power cord must be plugged into a properly wired receptacle before connecting to the equipment’s input or output terminal.

- The service manual which is provided along with the equipment should be studied thoroughly before starting troubleshooting. The caution statements, warning statements and other information should be read carefully.

- Always disconnect the power to the equipment before removing the cabinet panels and before cleaning or replacing parts to avoid electric shock hazard.

- The circuit boards should be handled by edges to avoid inaccurate performance because of static charges, dirt, dust etc. Check the conditions of all external cables for splits, cracks, twists and so on

1.5 Summary

For the process of troubleshooting, preparing the circuit diagram is the initial and basic process performed by the maintenance technician.

The components can be physically interconnected to each other using solder, wire-wrap and printed circuit board methods.

Any electronic system consists of an element, component, assembly and equipment. All these parts together make a complete electronic system.

The troubleshooting process consists of fault establishment, fault location and fault correction.

Functional area approach, Split half method, Divergent path, Convergent path, Feedback path, Switching path are the common troubleshooting techniques. Which technique has to be applied totally depends on the type of system.

To start the process of troubleshooting, first the technician should have a close visual inspection of the system. He should understand the basic functionality of the system. Then he can proceed to analyze the cause of the trouble.

A well designed, well engineered, thoroughly tested, and properly maintained system should, ideally, never fail in operation. However, in practice it is observed that even the best design, manufacturing and maintenance efforts do not completely eliminate the occurrence of failures. There can be various causes and types of failures.

For the enhancement of system reliability, it is necessary that the design engineer understands the causes of failure, so as to trace the deficiency in the system. The primary concern is to identify the correct causes of failure and to decide on appropriate corrective action to assure higher system reliability.

Learning objectives

- Understand the technical meaning of failure

- Know the symptoms of failure

- Study the causes of failure

- Study Early Failure, Random Failure and Wear out Failure

- Know what is Failure Rate, Mean Time to Failure, Mean Time between Failure and Mean Time to Repair

2.1 Failure Symptoms

Failure

The reliability of equipment improves considerably when it is operated under certain favorable conditions (which may vary from equipment to equipment) such as operating the components well below the maximum ratings, subjecting the components to minimum vibrations and shocks, etc. In spite of all the favorable operating conditions, failures are seen to occur.

The frequency at which the failure occurs is termed as reliability of the system. The less is the occurrence of failure, the more is the reliability of the system.

Definition of Failure

Any equipment or a system may breakdown due to a faulty component. For each component or item, the properties that it must possess in the course of its use are listed.

A deviation in the properties of the component or item from prescribed condition is considered as a fault. A state of fault is denoted by the term failure.

Failure of equipment refers to its inability to perform its required function, such as when characteristics change to such a degree that it can not perform its specified level of performance.

The fundamental sources of failure include many aspects of design, material selection, material imperfections, fabrication and processing, assembly, inspection, testing, quality control, storage and shipment, service conditions, mechanical and chemical damage to system.

Failure Curve

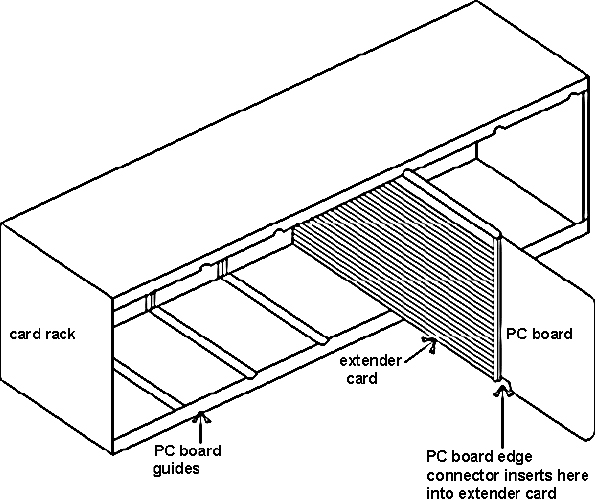

Failure Curve)

The traditional bathtub curve in figure 2.1 indicates component life in three stages.

During the first stage, failure rate begins high and decreases rapidly with time. This stage is known as Infant Mortality Period and it has a Decreasing Failure Rate (DFR). The infant mortality period is followed by a steady state failure rate period, which is usually long. This period is known as random failure period or useful life of the equipment and this part of the curve being identified as normal operating life curve.

In the third stage where the curve ends, i.e. beyond the useful life period, there is a gradual increase in failure rate. This is a period of ageing and wears out with increasing failure rate.

Equipment Failure

Failures may be partial failures resulting from deviation in characteristics or parameters beyond the specified limits but not such as to cause complete lack of required function. If the characteristics deviate beyond the specified limits such as to cause complete breakdown of the required function, it is called as complete failure.

Failures can be anticipated by prior examination, whereas in some cases, it can be a sudden failure which could not be predicted on routine examination. A sudden and complete change in equipment performance is called as catastrophic failure.

These may be caused by an open circuit or short circuit failure which is irreversible.

Failures may also occur gradually and in a partial manner. Such a type of failure is referred to as degradation failure. These failures are encountered mostly with analog systems when some noise or disturbance is present.

Symptoms

Symptoms are useful to locate the general area of problem. The symptoms are sometimes described by the equipment owner or user. In an industrial electronic plant, it may be the foreman of the division who uses the equipment. In consumer electronic equipment, the description is often from the customer who owns the equipment.

The most reliable symptom analysis is given by the technician after energizing the equipment. Technicians know that certain symptoms in a system usually mean that a certain component has failed.

Symptoms are indeed a valuable guide for troubleshooting. However, one should avoid basing a complete troubleshooting procedure on the knowledge of symptoms alone. For example, distortion in radio’s output sound can be caused by different reasons such as low terminal voltage of aging battery, overuse of transistor, a tear on a speaker cone and so on.

An item is considered to have failed because of one of the following three conditions:

- When it becomes completely inoperable

- When it is still operable but is no longer able to perform its intended function satisfactorily, or

- When serious deterioration has made it unreliable for its continuous use, thus necessitating its immediate removal from service for repair or replacement

2.2 Failure Causes

For the enhancement of system reliability, it is necessary that the design engineer understands the causes of failures, so as to trace the deficiency. Equipment failures take place due to many reasons. The primary concern is to recognize the causes of failure and to take corrective action to achieve higher reliability. The causes can be classified as follows:

Design Deficiency

- Little engineering efforts and changes in design

- Improper choice of components

- Upgrading of a part

- Inadequate information on failure analysis of components

- Insufficient design criteria

- Insufficient prototype testing for meeting both reliability and performance specification

- Excessive heat development inside the equipment and lack of cooling

- Poor mechanical layout of components, assemblies and panels

Production Deficiency

- Imperfection in purchase of material for substandard manufacturer or company

- Unsuitable storage method and unduly long storage period of components

- Absence of training programmers to employ correct and effective production techniques

- Negligence in performing environmental tests like temperature cycling, operation of equipment at elevated temperature for specified period

- Lack of proper working environment, ill-ventilated, poor illumination and dusty assembly shops

- Lack of inspection of goods, sampling tests and inspection

- Insufficient testing and inspection of finished product

Processing Deficiency

- Incomplete or ambiguous specification, specification of unsuitable processing procedures

- Changes in the specification without complete evaluation

- Improper heat treatment, electroplating, welding

- Cold forming, machining, improper identification marking

Assembly Errors

- Undetected errors in assembly by the manufacturer or the purchaser

- Improper matching of various signals used or generated by the components on the terminal board at the time of assembly

- Improper prescribed order of the components collected on the terminal board

Careless Storage and Transport

- Undue long storage of equipment before its dispatch to the customer

- Improper packaging which may be unable to protect the equipment from corrosion or mechanical damage

- Excessive vibrations and mechanical shocks during transportation of equipment from manufacturer to the user

Improper Working Conditions

- Presence of abnormally severe conditions of speed, temperature, loading and lack of dust free areas, air-conditioned rooms

- Using the equipment without following manufacturer’s instructions, warnings and cautions

- Inadequate maintenance policy and after sale service by the manufacturer

- Usage of the equipment beyond its lifetime

- Aging of the equipment

- Poor operating ability of the equipment with the possibility of high degree of operator error

- Lack of preventive measures

2.3 Failure Types

During the complete life cycle of the operation of a system, failures are broadly classified into three categories as follows:

- Early Failure

- Random Failure

- Wear out Failure

Failure Types

Early Failure

- As the name suggests, errors occur during the early life of the system’s operation.

- These failures could be attributed to variation in manufacturing process and poor quality control techniques during production.

- The method of inspection and improper assembly of components may also lead to early failure.

- They are also known as Infant Failures. These can be eliminated by de-bugging or burn-in process.

- The testing procedure consists of monitoring system characteristics by simulating conditions of actual use.

- The weak and substandard components which fail early are replaced by good and tested components.

- Debugging is generally done prior to delivering the system to the user to ensure the detection and elimination of early failures.

Random Failure

- They are also known as chance failures and are predominant during the actual operation of the system.

- They occur at random, irregularly and unexpectedly.

- These failures are caused by sudden stress accumulations beyond the design strength of the component.

- It is highly unpredictable when the chance failures will occur, however they obey certain rules of behavior so that the frequency of their occurrence during sufficiently long periods is approximately constant.

- The phase during which only chance failure occur is called useful life of the system.

- It is normally not easy to get rid if these failures but reliability techniques like duplicating the components, incorporating the safety margins in design and so forth will help reduce the occurrence of random failures

Wear out Failures

- Wear out failures are caused due to aging or wearing out of the components.

- These failures will occur if the system is not maintained properly and the frequency of such failures increases rapidly with time.

- In general, these failures can not be completely eliminated but can be arrested for sometime by carrying out preventive maintenance of the system at regular intervals.

- Preventive maintenance is planned in such a way that the maintenance period between two maintenances is shorter than the mean wear out life of the system.

2.4 Some Useful Terms in Failure

Failure Rate

The failure rate is expressed in terms of failures per unit of time, such as failures per hour or failure per 10 or 100 hours. The failure rate of a component can be calculated by operating large numbers of the component for a known period and noting the number of failures that take place during that period.

It is computed as a simple ratio of number of failures, f, during a specified test interval, to the total test time of the items undergoing test. Thus:

Failure Rate = f / T,

Where: f = number of failures during the test interval

T = total test time

For example, suppose 1000 transistors are put on test, out of which 50 fail over a 1000-hour period, and then by definition, the failure rate is given by following equation:

Failure Rate = 50 / 1000

= 0.050 per 1000 hours

= 0.050 / 1000 per hour

= 5 * 10 -5 per hour

Often the failure rate is expressed as a percentage.

Failure Rate = 50 / 1000 * 100 % per 1000 hours

= 5 % per 1000 hours

The smaller the value of the failure rate, the higher is the reliability of the system.

Mean Time to Failure (MTTF)

From the failure rate data, it is possible to calculate the ‘mean time to failure’ (MTTF). If one transistor is used in the system, then:

MTTF = 1 / 5 * 10 -5

= 20,000 hours

It is also calculated on the basis of the results of life testing of components. For example, if there are 3 transistors which are tested until failure, and the time to failure were 300, 600 and 400 hours.

Total test time = 300 + 600 + 400

= 1300 hours

MTTF = Total test time / number of components

= 1300 / 3

= 433.33 hours

MTTF is normally applied on items which can not be repaired, such as resistors, capacitors, diodes, transistors, etc.

Mean Time between Failures (MTBF)

The Mean Time between Failures (MTBF) is the reciprocal of the constant failure rate or the ratio of the test time to the number of failures. It is measured by testing it for a time period (T), during which faults may occur. The equipment is tested after every repair of fault:

MTBF = 1 / Failure rate

= T / f

Where: f = number of failures during the test interval

T = total test time

The MTBF of a system is estimated by first determining the failure rate of each component and then summing them all up to obtain the system failure rate. If a small system has for components with individual failure rates FR1, FR2, FR3, and FR4 respectively, the total failure rate of the system is:

Total Failure rate = FR1 + FR2 + FR3 + FR4

MTBF = 1 / Total failure rate

Mean Time to Repair (MTTR)

Mean Time to Repair is an important consideration for selecting a system. It is the average time required to bring a system from a failed state to an operational state. It is defined as the total corrective maintenance time divided by the total number of corrective maintenance actions during a given period of time. MTTR includes the time taken to diagnose, locate and repair the fault.

2.5 Summary

A deviation in the properties of the component or item from prescribed condition is considered as a fault. A state of fault is denoted by the term failure.

The component life is divided into three stages. The first stage is Infant Mortality Period, the second stage being Random Failure Period and the third stage is beyond the useful life period which is the Wear out Stage.

Symptoms are usually the very first information about the failure. Symptoms are generally provided by the user of the equipment. However, the maintenance engineer should not decide the path of troubleshooting on the basis of symptoms alone.

There can be various reasons for failures: Production deficiency, Processing deficiency, Assembly errors, inadequate storage and transport conditions are some of the major causes of failure.

Failure Rate, Mean Time to Failure, Mean Time between Failure and Mean Time to Repair are some important mathematical terms in failure.

Device Troubleshooting is divided into two sections. The first section consists of a study of various hand tools and testing and measuring instruments which are used in troubleshooting of electronic circuits (analog). Digital troubleshooters are explained in chapter 5. The second section consists of actual testing and troubleshooting of various components and devices (chapter4).

This chapter provides a brief overview of tools such as Spanners, Wrenches, Screw Drivers, and Files. Analog multimeter, digital multimeter, oscilloscopes are the basic test and measuring instruments required in troubleshooting to test and measure three basic quantities: current, voltage and resistance. This chapter shows how to use these instruments.

Learning objectives

- Study various tools required in servicing

- Study of test and measuring instruments like multimeter, oscilloscope

- Understand multimeter for the measurement of current, voltage and frequency

- Understand oscilloscope for the measurement of amplitude, frequency and phase difference

- Study of Continuity Testers, Waveform Generator, Resistance and Capacitor Boxes

3.1 Tools for Servicing

In the absence of proper tools, the servicing of equipment, even by the best technician, is incomplete. Availability of proper hand tools and their prior knowledge is essential for the best troubleshooting results.

Hand Tools

A maintenance technician is expected to handle a wide variety of tools in the proper way as per the needs. Some of the tools which are often used are listed below.

Spanners (Wrenches)

They are used for tightening nuts and bolts. A torque is exerted which is applied to the head of the bolt or nut. Below are some types of spanners.

Open ended spanners of different sizes

Open ended Spanners

They are used primarily on large hexagonal nuts. The opposite ends of the spanner have successive jaw sizes.

Ring Spanners

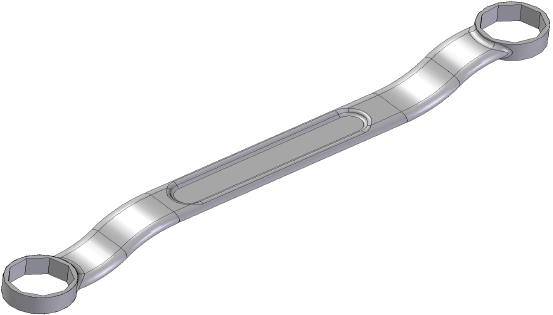

Here both the ends have closed rings whose inner sides are serrated to have six point grip or more. Both the heads are offset relative to the handle.

Ring Spanner

They can be placed on the nut only from the top and can be used with one hand without possibility of slippage.

Adjustable Spanners

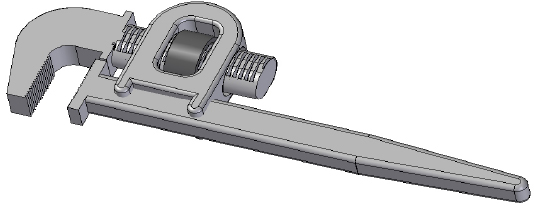

As the name suggests the jaw size of the spanner is adjustable.

Adjustable Spanner

When no correctly fitting spanner is available, adjustable spanners are used.

Allen Key

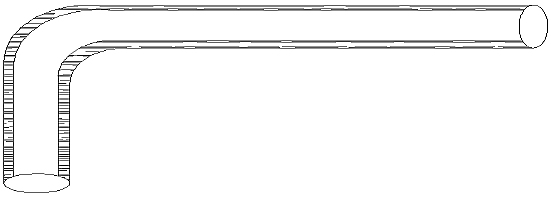

Allen Wrenches

Allen Wrenches are also known as Hexagonal Socket Bar Spanner (Allen Key). They are most useful for opening control knobs. These are right angled rods of hexagonal cross section with one short arm and one long arm.

Allen Wrenches

The short arm is used for assembly and the long arm is used for tightening. They also come as a set in metric or inch sizes. Allen Wrenches are most useful for opening many control knobs.

Screw Drivers

These are the most common tools for securing screws. Following are the two types of screw drivers:

Flat Blade Screw Driver

They are used in practice for slotted screws.

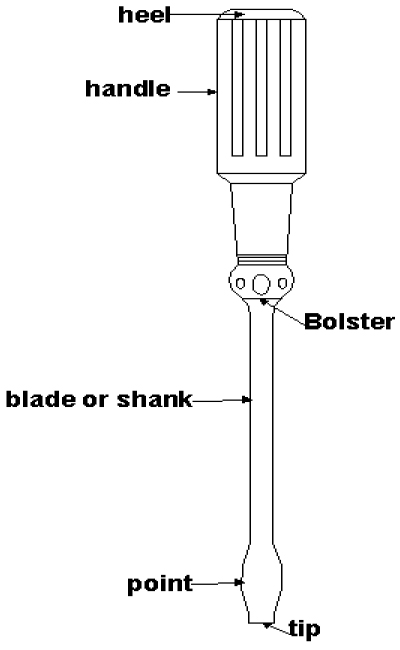

Standard Screw Driver

The above figure shows various parts of screw driver. The handle is usually made of tough, transparent colored plastic and shaped to provide a firm, comfortable grip. The handle has a smooth, semi-rounded heel which fits the palm comfortably.

The blade or shank is made of steel which is heat treated and tempered to apply torque to the screw head. The blade and tip are chrome plated.

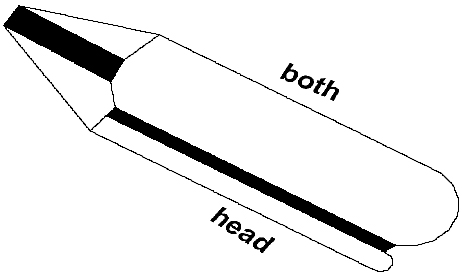

Flat Blade Screw Driver

For a flat blade screw driver the width of the blade and the thickness of the blade should be correct.

Philips Head Screw Driver

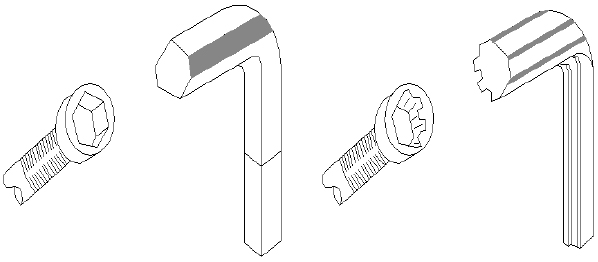

These screw drivers have star-shaped holes in their heads as opposed to straight slots. There are four (No. 1 to No, 4) standard sizes of Philips screw drivers. No. 1 and No. 2 are usually needed.

Philips Head Screw Driver

The star-shaped hole in a Philip’s screw driver and the tip of a Philip’s screw driver must fit together properly so that the walls of the screw head or the tip of the driver, or both, will not be damaged.

In addition, there are some other special types of screw drivers which are used occasionally. For small and delicate work Jeweler’s screw driver sets are available. The barrel of the handle is knurled with a top finger rest.

Ratchet’s Screw Drivers have a selector level that will allow the screw driver to rotate freely in either the clockwise or anticlockwise direction and obtain the ratchet driving action in the other direction.

Nut Drivers

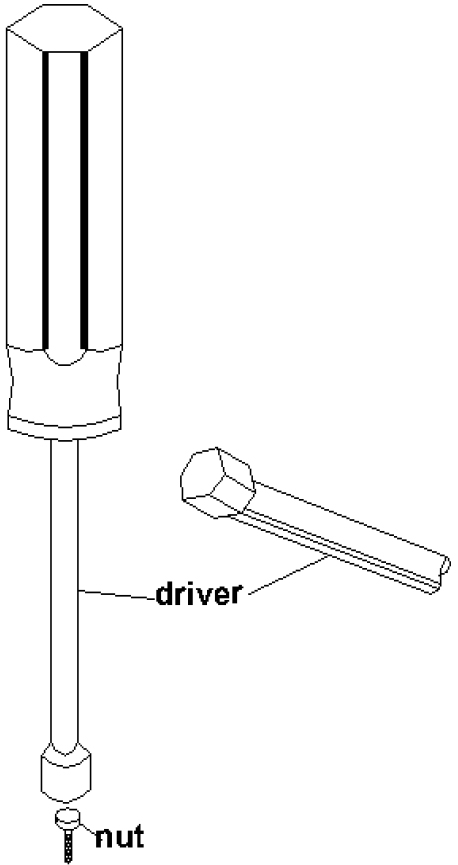

Nut drivers are used as screw drivers but are designed to accommodate hexagonal types of machine nuts instead of screw heads.

Nut Drivers

They are very useful in mounting a nut on a threaded stud and in holding a nut while its screw is being tightened.

Files

Files are made of hardened high carbon steel. Filing is the most important skill to be acquired in electronic fabrication. Files are classified according to their length, cut of teeth and cross-section. Following are files of different cross section:

Files of different cross section

During repair work, if there is a need to use a different sized replacement component, like a potentiometer or a fuse carrier. In those cases files are very useful to enlarge holes. They are also used to smooth the scratch marks on surfaces.

Practical Tips

- The technician should carefully see the size of the screw and the type of opening to select the particular driver.

- A screw driver should not be used at an angle to the screw.

- The technician should be cautious enough to insulate himself from electricity. The driver’s handle or covered blade is not enough for insulation.

- When filing soft materials, there is a possibility that the waste metal may clog the file teeth. In that case the file teeth should be cleaned using file cleaners.

- Never do filing near open electronic equipment as the filings may enter the equipment, causing electrical shorts.

3.2 Test and Measuring Instruments

There are many types of testing and measuring instruments available for electronic troubleshooting. A certain amount of personal opinion is involved in troubleshooting methods. One may prefer to use a voltmeter for troubleshooting problems, another may use oscilloscope leads. Although, a personal choice is always there, the technician should be familiar with all the methods, advantages and disadvantages, limitations, and types of troubleshooting instruments.

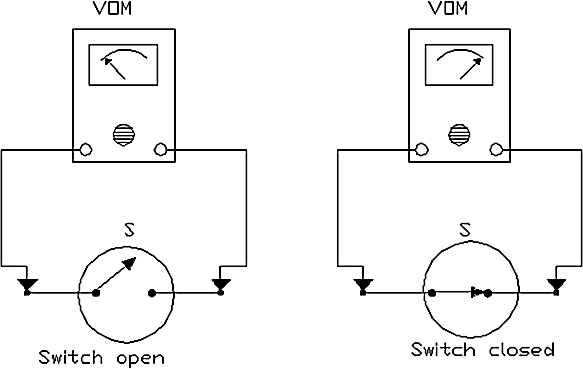

Analog and digital multimeter [volt-ohm-multimeter (VOMs)] is available for troubleshooting analog circuits.

Multimeter

The multimeter is the most useful instrument for the troubleshooting technicians. This instrument facilitates the measurement of DC voltage, AC voltage, DC current and resistance values. With proper accessories it can also measure other parameters like high frequency signals, high voltages and so on.

Voltmeters and ammeters both AC and DC and ohm-meters are available in various ranges and configurations. A multimeter is a combination of all these meters which makes it very useful in the field.

An analog multimeter is used when merely the presence of a value near one specified is required rather than a measured value that is exactly as expected. An analog indication of approximate voltage value is more quickly observed as compared to digital reading. They are less susceptible to extraneous noise.

When a high accuracy is required, especially when very small changes in a level need to be detected, a digital multimeter is preferred.

Analog Multimeter

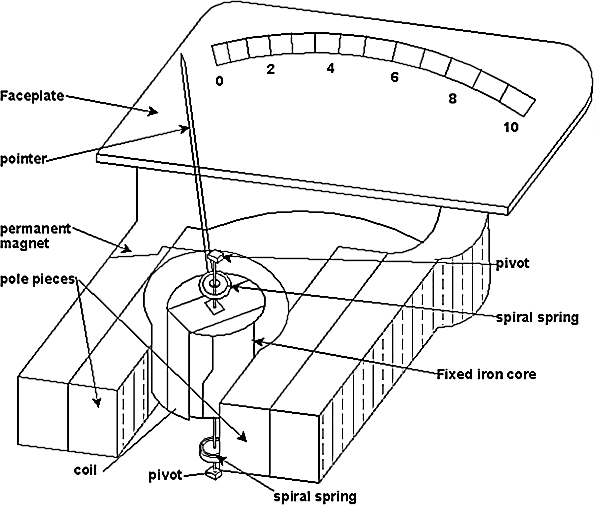

Analog multimeter is the most widely used test and measuring instrument. It operates with a permanent magnet moving coil, which can become a DC voltmeter, an AC voltmeter, and DC milli-ammeter or an ohm meter. Sometimes an AC current measuring facility is also present.

It has a coil of fine wire wound on a rectangular aluminum frame. It is mounted in the air space between the poles of a permanent horse-shoe magnet. Refer to the following figure:

Moving coil meter

When electric current flows through the coil, a magnetic field is developed that interacts with the magnetic field of the permanent magnet to force the coil to rotate. The direction of rotation depends upon the direction of electron flow in the coil. The magnitude of the pointer deflection is proportional to the current. In usual meters, the full scale deflection (FSD) is about 90 degrees.

Using the Multimeter

The multimeter operates without any error if some preliminary adjustments are undertaken while using the multimeter. A scale plate of a standard multimeter is shown in the following figure:

Typical scale of Analog multimeter

Following are the settings of the multimeter:

- Place the multimeter flat on a bench with its face up.

- Set the range switch to OFF.

- Short two test probes together.

- Note if the meter pointer indicates exactly 0 at the extreme left end of the scale.

- If it does not read 0, turn the screw o the meter movement slowly until the proper 0 reading is obtained.

Measurement of Current

The moving coil meter is basically sensitive to current and is therefore an ammeter. For the direct current measurement, place the meter (ammeter to measure current) in series with the circuit. When the ammeter is included in the circuit, its internal resistance adds up, thereby reducing the current in the measuring branch. Usually, this resistance is small and can be ignored.

For alternating current measurement, rectifier type meters are used which will respond to the average value of the rectified alternating current. The meter has to be calibrated in amperes rms (root mean square) for the measurement of sine waves.

Measurement of Voltage

The current meter can be used to measure voltage. The moving coil meter has a constant resistance. So, the current through the meter is proportional to the voltage.

To measure the potential difference between two points, connect the two voltmeter leads to these points. So, in contrast with the ammeter, the voltmeter is connected in parallel with the circuit whose potential has to be measured.

To measure AC voltage, rectification is required. As in the AC current meters, AC voltmeters respond to the average value of the rectified voltage but are calibrated in volts rms for a sine wave.

Measurement of Resistance

The moving coil meter can be used to measure unknown resistance. Test probes are short circuited and the ohms adjust control is turned so that the current through the total circuit resistance has a full scale deflection.

An ohm meter is never used while the circuit is in operation. Sometimes the resistances depend upon the circuit conditions, in that case measure the voltage across the resistance, the current through it and calculate the resistance.

Operating Suggestions

- Set the range switch to the proper position before making any measurement.

- It is always advisable to start from the highest range in case of unknown measurement. Never apply more voltage or current than the amount noted in each position.

- Remove the parallax for the most accurate readings. Look at the scale from the point where the pointer and its reflection on the mirror come together.

- When the meter is not in use, keep the range selector in the OFF position and remove the batteries.

- Always connect the meter in series with the load when current is measured. Select the desired current range and connect the meter in series with the circuit under test.

- The polarity of the leads is not important when measuring AC. The sensitivity of the meter is different for the AC and DC ranges.

Practical Tips

- Do not measure voltage across a high-resistance or high impedance circuit with a meter that has relatively low input impedance.

- Do not use a meter to measure ICs with MOSFET unless you know the probes are static free.

- Avoid using a voltmeter (instead of a logic probe) to measure logic 1 and logic 0 in a digital circuit.

- In case of AC measurements, the meter movement responds to the average value of rectified current and therefore there could be an inaccuracy in measurement because of different wave shapes. If the applied waveform is non sinusoidal (square or triangular) then the rectified type of AC voltmeters is subject to errors. Therefore it is advisable to consult the manufacturer’s chart for the factors to be taken into consideration to get the correct value.

- The batteries in the meter should be checked frequently for correct operation in the resistance ranges.

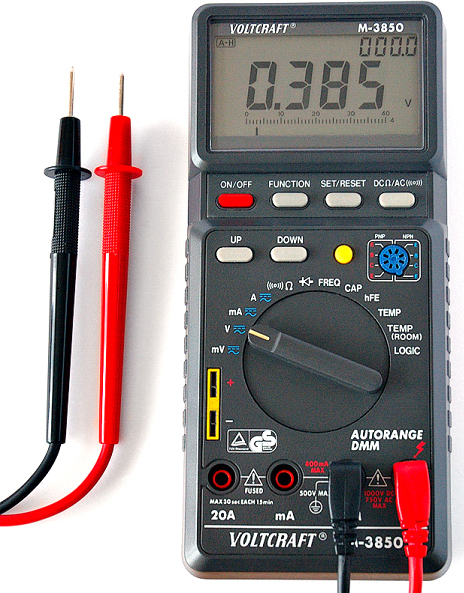

Digital Multimeter

In the analog type of multimeter the value of the parameter being measured is estimated from the position of a pointer along a calibrated scale. Even when using a high grade meter of this type it is difficult to take readings with a precision which is better than about 1 percent of the full scale value.

This limitation is largely imposed by the physical arrangement of the scale and the pointer scheme. For more precise measurements it would be better if the actual value of the voltage or current could be displayed directly as a numerical value.

The digital meter displays the measurements as discrete numerical instead of a pointer deflection on scale. They have high input impedance and the user has to only set the function switch and read the measurement.

The basic function performed is an analog to digital conversion. The analog signal input might be a DC voltage, an AC voltage, a resistance or an AC or DC current. Thus a digital value is converted to a proportional time duration which in turn starts or stops an accurate oscillator. The oscillator output is fed to a counter which drives a digital readout arrangement in terms of voltage values.

Digital Multimeter

DMM is classified according to the number of full digit displayed. An over range digit is an extra digit to allow the user to read values beyond full scale. An over range digit is sometimes known as ‘one half’ digit. For example if a signal changes from 9.999 to 10.012 a four digit display will require a change in range and the second measurement will read 10.01V. The 0.0002 will not be read. On a Four and Half digit display this problem will not occur.

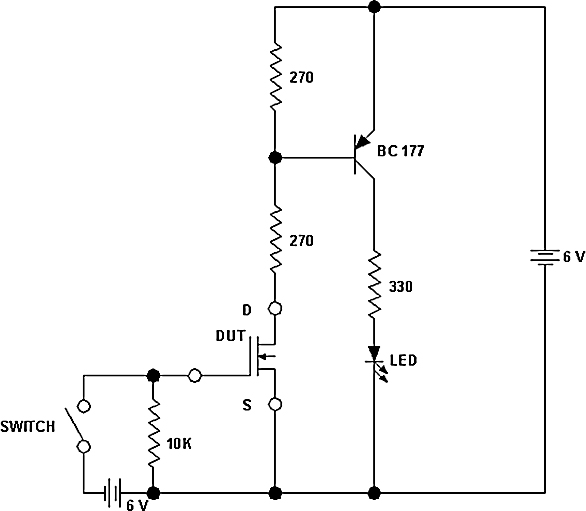

Apart from reading the values of voltage, current and resistance, DMM can also be used to measure temperature, frequency, duty cycle, capacitance, and other parameters with the help of optional accessories. They are used to perform Diode Checks and Continuity Checks in a circuit.

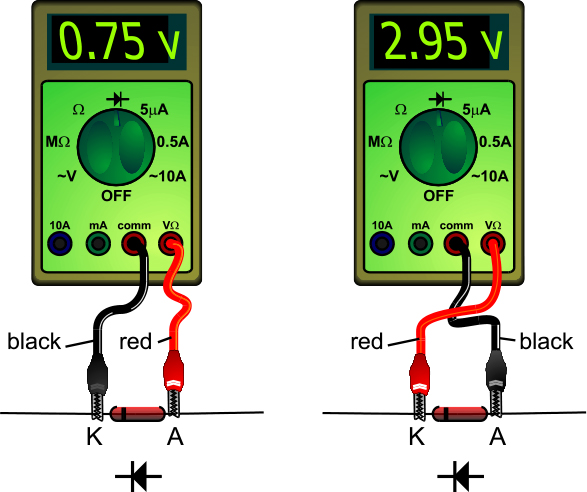

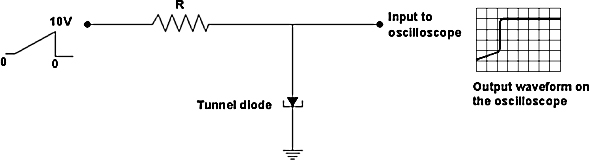

Diode Check using DMM

The diode is a semiconductor device, which conducts direct current in one direction only. In other words, the diode exhibits a very low resistance when it is forward-biased and an extremely high resistance, when it is reverse-biased. An ohmmeter applies a known voltage from an internal source (batteries) to the measured resistor. Theoretically, this voltage can reach 1.5 V or 3 V. The diode requires a voltage of 0.7 V to become forward-biased. Therefore, if the positive test lead of the ohmmeter is connected to the anode and the negative test lead of the ohmmeter is connected to the cathode, the diode becomes forward-biased. In this case, the ohmmeter reads a very low resistance. If the test leads are reversed with respect to the anode and the cathode, the diode becomes reverse-biased. Then, the ohmmeter reads a very high resistance. Thus an ordinary ohmmeter can be used to test a diode.

Most digital multimeters (DMMs) have a diode test function. It is marked on the select switch with a small diode symbol. When the DMM is set to diode test mode, it provides a sufficient internal voltage to test the diode in both directions. The positive test lead of the DMM (in red color) is connected to the anode, and the negative test lead of the DMM (in black color) is connected to the cathode. If the diode is in good working order, the multimeter should display a value in the range between 0.5 V and 0.9 V (typically 0.7 V). Then the test leads of the DMM are reversed with respect to the anode and the cathode. As the diode in this case appears as an open circuit to the multimeter, practically all of the internal DMM voltage will appear across the diode. The value on the display depends on the meter’s internal voltage source and it is typically in the range between 2.5 V and 3.5 V.

Properly Functioning Diode

A defective diode appears either as an open circuit or as a closed circuit in both directions. The first case is more common and it is mainly caused by internal damage of the pn-junction due to overheating. Such a diode exhibits a very high resistance when it is both forward-biased and reverse-biased. On the other hand, the multimeter reads 0 V in both directions if the diode is shorted. Sometimes a failed diode may not exhibit a complete short circuit (0 V) but may appear as a resistive diode, in which case the meter reads the same resistance in both directions (for example 1.5 V). This is illustrated in Figure 3.16.

Defective Diodes

As was mentioned earlier, if a special diode-test function is not provided in a particular multimeter, the diode still can be checked, by measuring its resistance in both directions. The selector switch is set to OHMs. When the diode is forward-biased, the meter reads from a few hundred to a few thousands ohms. The actual resistance of the diode normally does not exceed 100 Ω, but the internal voltage of many meters is relatively low in the OHMs range and it is not sufficient to forward-bias the pn junction of the diode completely. For this reason, the displayed value is higher. When the diode is reverse-biased, the meter usually displays some type of out-of-range indication, such as “OL”, because the resistance of the diode in this case is too high and cannot be measured from the meter.

The actual values of the measured resistances are unimportant. What is important, though, is to make sure that there is a great difference in the readings, when the diode is forward-biased and when it is reverse-biased. In fact, that is all you need to know. This indicates that the diode is working properly.

Oscilloscope

So far we have looked at meters which give a picture of the static levels of voltage or current. For more compete tests on the operation of a circuit, we need to be able to examine the way in which the signal varies with time. This involves displaying a graph of the signal being examined against a base of time, and the instrument employed for this is the Oscilloscope.

It gives a visual indication of what a circuit is doing and shows what is going wrong more quickly than any other instrument. Multimeter can detect the presence of signals and if the shape of the signal is known the average, peak, rms or peak to peak can be calculated. However, if the waveform is not known, then this is not possible. Noise may be superimposed on the signal and the multimeter will not be able to give the proper information. The oscilloscope gives a true and clear picture of the waveforms.

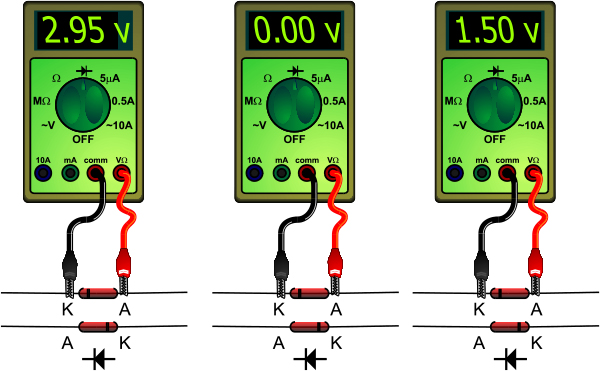

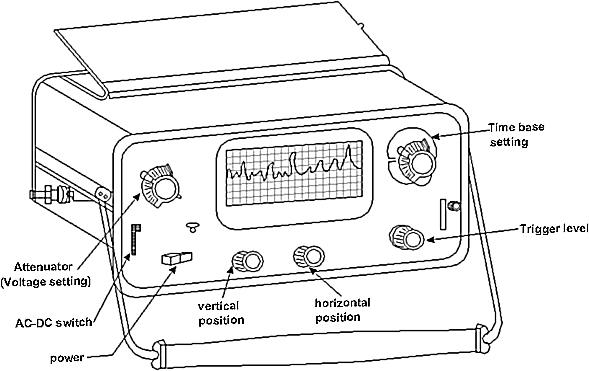

Understanding an Oscilloscope

The following figure shows all the essential controls on the front panel. The controls can be present in some different form than shown, but they have to be present in the oscilloscope.

Controls on an oscilloscope

The controls are as follows:

- ON / OFF control

- Focus Control

- X and Y position controls

- Trigger, sync or Level control

- Intensity or Brilliance control

Sometimes the ON / OFF control can be combined with Intensity / Brilliance control.

The instrument is directly plugged in the mains supply. After switching on the instrument, wait for a while until the CRT heater warms up. Turn the Brilliance control to clockwise direction until you observe a horizontal line of the trace on the screen.

If the trace does not appear on the screen then turn the Brilliance control right up to the fully clockwise direction. Turn Time/cm control to the slowest speed, but not to the off position. With these settings, a light spot should appear on the screen moving slowly from left to right.

Still if nothing is seen, adjust the Trig/Level control in clockwise direction and observe if something appears. Adjust the vertical and horizontal position controls until the trace appears.

If all the above steps do not result in showing a trace on the screen, the instrument is faulty. Unplug the mains and check the fuses.

After getting a trace on the screen use vertical and horizontal position controls to start the trace at the left hand side of the screen and lie along the centre line. Focus control is used to get the line as thin as possible. Reduce the Brilliance setting to a comfortable viewing level.

When making oscilloscope measurements, a pair of probes is very valuable and this facilitates making a contact on the point of measurement in a convenient manner. Probes connect the measurement points in the device under test to the inputs of the oscilloscope.

Input Probes

When the signals being examined have relatively low frequencies, such as the waveforms expected of an audio amplifier, the capacitance of the test leads usually poses no problem and has little effect on either the waveform of the signal being displayed or the circuit being tested.

When high frequency signals or fast pulses are being examined the capacitance between the core and screen of the input cable can affect the waveforms that are displayed and may upset the circuit being tested.

The capacitance between the core and screen of a typical 1 meter long input cable could be about 50pF which, when added to 50pF input capacitance of the amplifier will give a total shunt capacitance of 100pF across the circuit being tested.

Suppose the circuit being examined is a video amplifier with a load impedance of 1K and the signal being examined is a 10Mz square wave. The displayed waveform on the oscillator will become triangular in shape because the capacitor is unable to charge and discharge fast enough through the amplifier load resistor to be able to follow the 10Mz square wave.

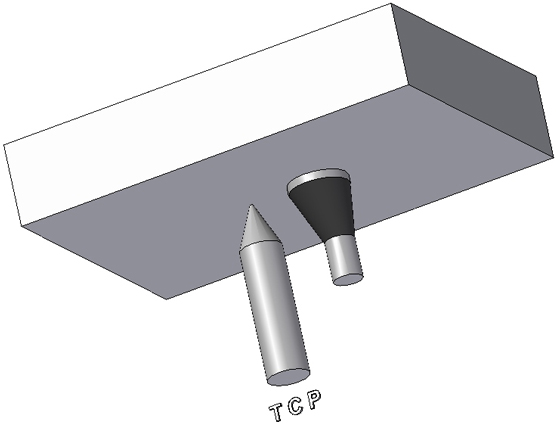

One way of overcoming this problem is a special probe at the input end of the test lead. This probe is usually arranged to act as a divide by ten attenuator and the circuit arrangement is as shown in the figure below:

Circuit arrangement of simple input probe

The dc component of the signal is attenuated by a pair of resistance, forming a simple potential divider. To balance up the capacitive reactance a small series capacitor is connected across R1. The value of this capacitor is adjusted so that it has a capacitive value which is 1/9 of that of shunt capacitance of the lead and the oscilloscope amplifier input.

For example where the oscilloscope has a shunt capacitance of the order of 50pF, the series connection capacitor becomes approximately 5pF. Now, when the probe is used to examine the video amplifier circuit, it presents an effective reactance of around 3K at 10Mz and will therefore have much less effect on the signal being examined.

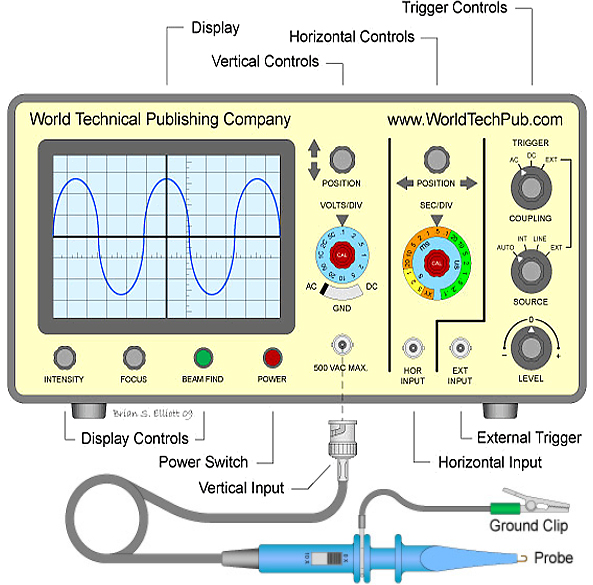

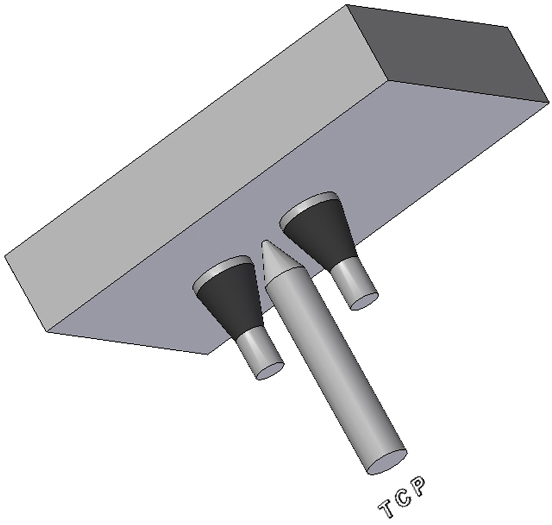

Probe Tests

When a probe is included in the input line, it is important to match the probe to the oscilloscope input. This is usually achieved by adjusting the small compensation capacitor in the probe to produce the correct results on a square wave input. Most oscilloscopes provide a square wave test signal for setting up input probes. This signal is applied to the probe input and the probe capacitor is then adjusted to give a correct square on the screen.

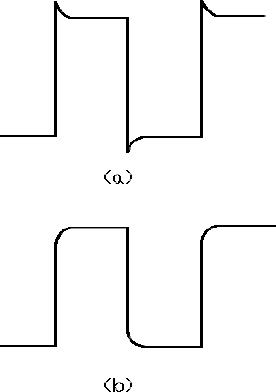

If the compensation capacitor in the probe is too large, it will not produce the correct attenuation ratio for high frequency signals. In a square wave input this will give rise to overshoot on the edges of the square wave as shown in following figure:

Effects of probe compensation adjustment (a), (b)

When the compensation capacitor is too small the higher frequencies are attenuated too much and this produces rounded corners on the square wave as shown in the figure (b).

With the correct setting of the compensation capacitor there could be no overshoot or rounding off on the edges of the square wave and the waveform is displayed correctly.

Calibration of the oscilloscope probe

When using an oscilloscope, it is very easy to plug the oscilloscope probe in and start to make measurements. Unfortunately oscilloscope probes need to be calibrated before they are sued to ensure that their response is flat. There is a built in calibrator on virtually every oscilloscope for this purpose. It provides a square wave output, and there is a small preset adjustor on the probe. With the oscilloscope probe connected to the output of the calibrator the shape of the waveform displayed on the screen should be adjusted until it is perfectly square. If the high frequency response of the probe is down then the edges of the square wave will be rounded. If it is up then the square wave edges will show overshoot.

Although a simple adjustment, it is essential that it is undertaken to ensure that the performance of the probe is correct.

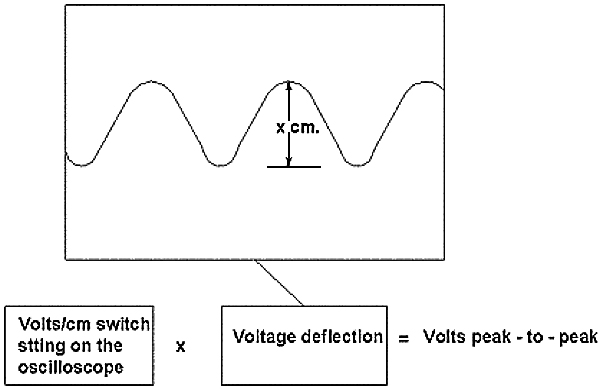

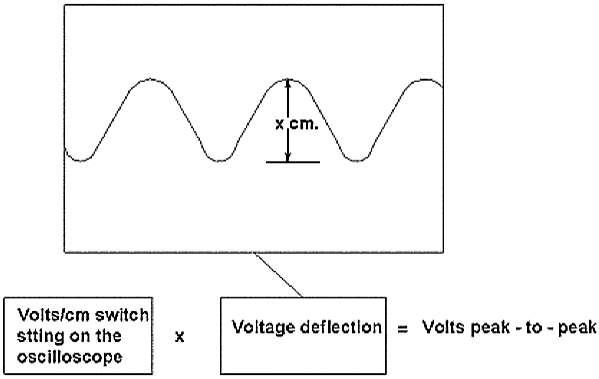

Measuring Amplitude with Oscilloscope

Oscilloscope’s greatly and effectively help in finding out the amplitude of voltage.

Voltage measurement

The number of centimeters on the vertical scale from the negative peak to the positive peak is counted. This count is multiplied by the setting of the volts per centimeter switch.

For example: if 5 V/cm is the volts/cm setting and the waveform measures 4.8V from peak to peak then the waveform voltage is 4.8 * 5 = 24V Peak to Peak.

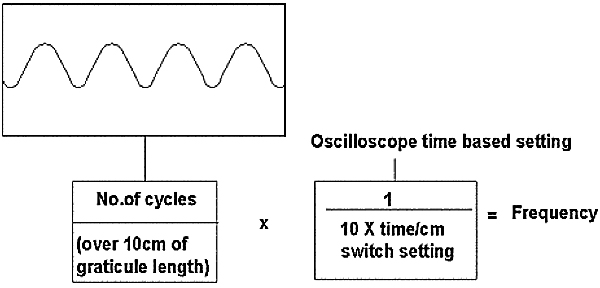

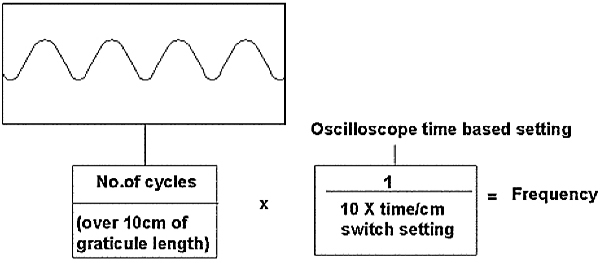

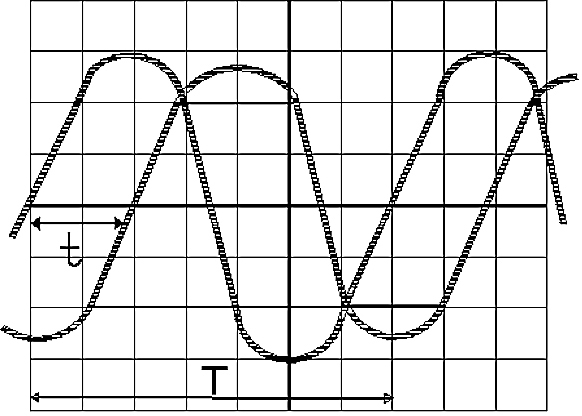

Measuring Frequency with Oscilloscope

For frequency measurement the time period of one complete cycle is measured. This is merely the horizontal distance between the two identical points on the neighboring waves.

Frequency measurement

This distance is then multiplied by the setting of the Time/cm switch and the period of one cycle is calculated. The reciprocal of this time is the frequency of the wave.

For example if the peaks of the waveform are 5 cm apart, and the Time / cm switch is set to 200 μ s / cm, the time of one complete cycle is 5* 200 = 1000 μ s = 1 ms and the frequency is 1 / 1000 = 1 KHz.

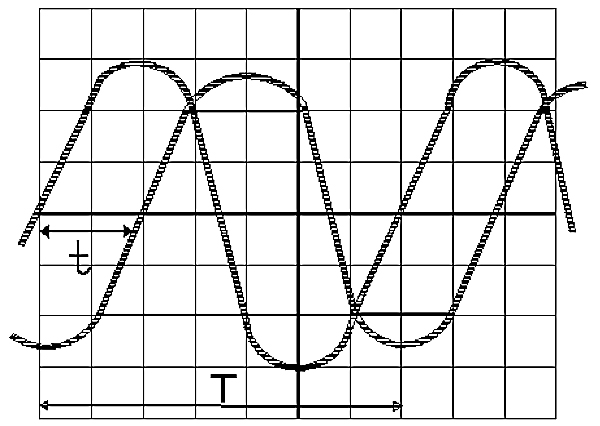

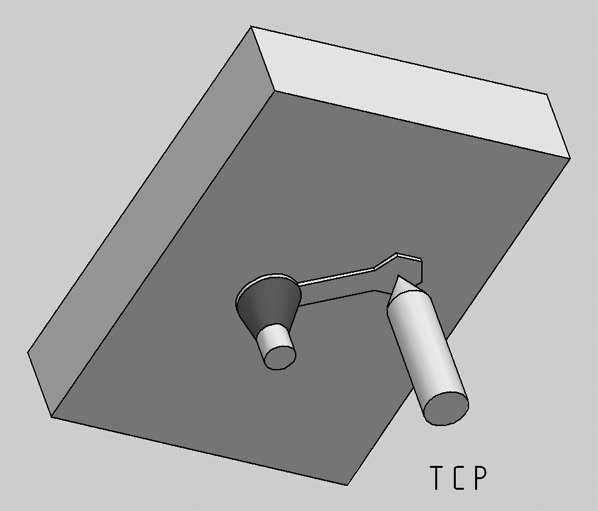

Measuring Phase Difference

If we have two signals of the same frequency and wish to measure the phase difference between them, we can do it by using a dual trace oscilloscope. One signal is fed to CHANNEL1 input and the other to CHANNEL2 input.

The VH1 position is adjusted to place the CH1 Trace so that it is centered about the horizontal axis of the screen. The CH2 trace is then moved to place it over the CH1 trace. The X position control is then adjusted to move the point where the CH1 trace crosses horizontal axis to line up with the left hand vertical line.

The distance between the crossing point of the CH1 trace and the corresponding point of CH2 trace is then measured along the horizontal axis as shown in the following figure. The total period of one cycle of CH1 waveform is also measured:

Measurement of Phase difference

The phase shift will be the difference in position between the two traces divided by the total wave period and the result is multiplied by 360 to get phase in degrees.

Lissajous Figures

If we have to compare the phase relationship between two AC signals, then apply one signal to X plate of the tube and the other signal to Y plate of the tube. This produces a display which is generally referred to as Lissajous figure.

On dual trace oscilloscope there is usually a position of TIME / DIV switch which selects the CH2 signal. With this mode selected one signal is applied to the CH1 input and the other to the CH2 input.

When the two signals applied have the same frequency and are exactly in phase, the result will be a diagonal line on the cathode ray tube which will run from the bottom left of the screen to the top right as shown in the following figure(a):

Typical Lissajous figures display

If one of the signals is now reversed in polarity, so that it is 180 degrees out of phase with another signal, the result is still a straight diagonal line but now it will run from the top left to bottom right of the screen as shown in figure (b).

When two signals are not quite in phase with one another, the diagonal line changes to an ellipse running diagonally from bottom left to top right of the screen as shown in figure (c).

As the phase difference is increased, the thickness of the ellipse will increase until it becomes a circle when the signals are 90 degrees out of phase as shown in figure (d).

The above results assume that the signals being compared are sine waves which are of the same amplitude. It is also assumed that the deflection sensitivities of X and Y circuits of the oscilloscope are the same. If the signal amplitudes or deflection sensitivities are not identical then the resultant image will be stretched in a direction with higher sensitivity.

When the waveforms being examined are not sine waves the Lissajous display becomes distorted but generally follows a similar type of pattern.

Analyzing waveform with Oscilloscope

An oscilloscope is an excellent tool to see what is happening in the circuit and with experience much can be gained from the correct interpretation of what is displayed.

If a sine wave is given to an amplifier and the oscilloscope displays a flat topped waveform when connected at its output, it means that clipping is taking place in the amplifier.

Calibration of Oscilloscopes

Oscilloscopes have always been an important measurement tool for the engineer. The design of oscilloscopes has evolved slowly from early instruments which were used to simply view a waveform, to oscilloscopes with calibrated ranges and graticules (grid) on the display to enable measurements to be made, up to the modern digital storage oscilloscope (DSO) which have many advanced measurement functions built in as standard. The latest designs now use digital LCD displays instead of the tradition CRT (cathode ray tube) and are putting even more measurement power in the hands of the engineer in ever more portable instruments. The oscilloscope is still evolving, the latest step is the scope meter which combines the functions of an oscilloscope with those of the DMM in one instrument. Each evolutionary step has added to the measurement capability of the oscilloscope, making the calibration of these instruments even more important.

All types of oscilloscopes require calibration of these main functions.

Oscilloscope Calibration : Amplitude

The oscilloscope amplitude is calibrated by applying a low frequency square wave and adjusting its gain to meet the height specified for different voltage levels (shown by the graticule line divisions on the oscilloscope). The voltages that are used for calibration are selected using the corresponding setting as per the amplitude ranges on the oscilloscope. Using this output the waveforms should be aligned with the graticule markings on the oscilloscope display. When calibrating the oscilloscope’s amplitude gain, it isl needed to set different voltages and check that the gain matches the graticule height lines on the display of the oscilloscope within the specifications as supplied by the oscilloscope’s manufacturer.

Oscilloscope Calibration : Time base/horizontal deflection

The time base of an oscilloscope is calibrated to ensure the horizontal deflection meets the manufacturers specifications. A time marker signal is generated from the calibrator of which the peaks are aligned with the graticule scale on the oscilloscope display.

Oscilloscope Calibration : Bandwidth reference

Calibration of bandwidth requires a constant amplitude sine wave of variable frequency up to and above that of the oscilloscopes specification. Many calibration procedures also call for a 50kHz reference level to set the start amplitude.

Oscilloscope Calibration : Trigger level

Trigger level can be tested by using a sinusoidal signal at 6 divisions high and adjusting the trigger level control to produce a stable trace starting at any point on either the positive or negative slope depending on scope selection. Sensitivity is tested by applying a much smaller signal (typically 10% of FS) and checking a stable trace can be obtained even when the position controls are used to move the trace to the top or bottom of the display. Bandwidth of the triggering and operation of the HF noise filters on some scopes can be tested by using the leveled sweep output and increasing the frequency or until stable triggering is lost.

Precautions

Make the following settings before switching on the oscilloscope or after completion of its use:

- Tune the stability control to auto

- Turn the intensity control to a fully anti-clockwise position

- Set vertical and horizontal position controls to midway round

- Turn volts / cm control to highest value of its range

- Set Time / cm control to 1 ms / cm or its nearest value

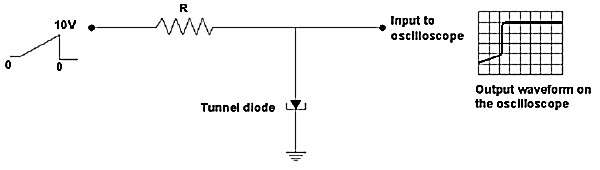

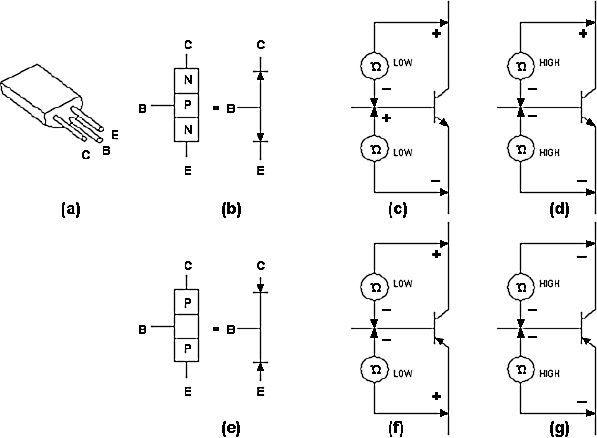

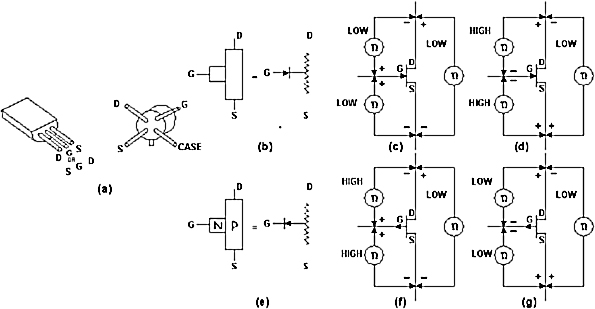

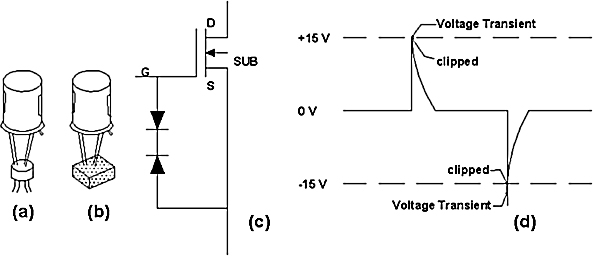

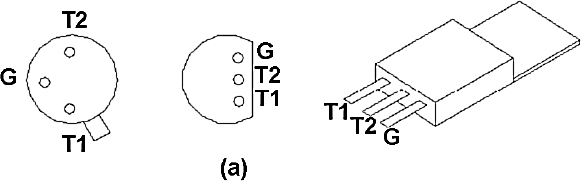

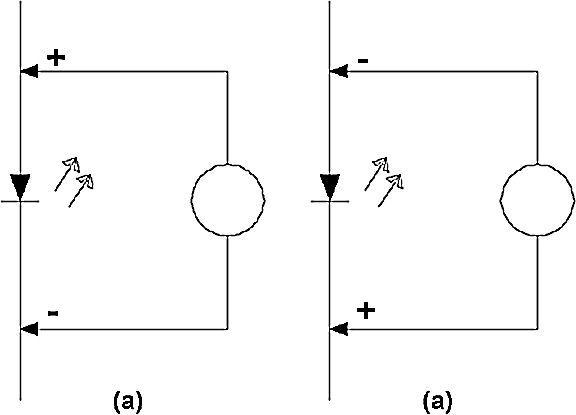

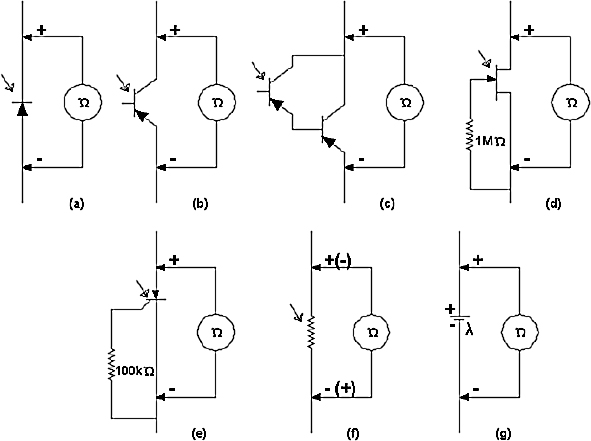

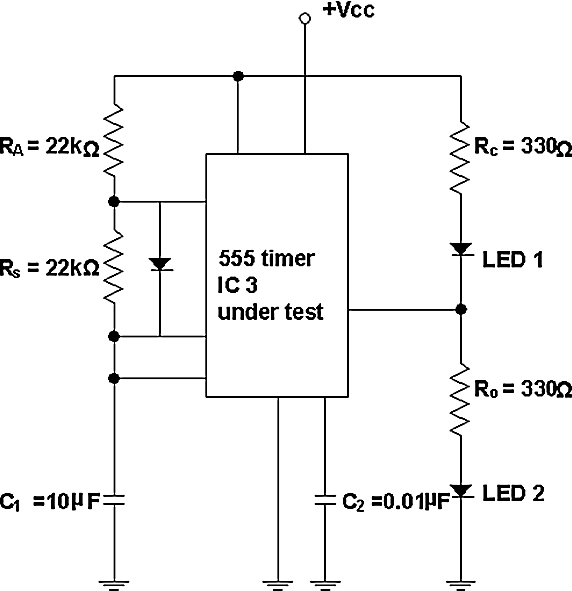

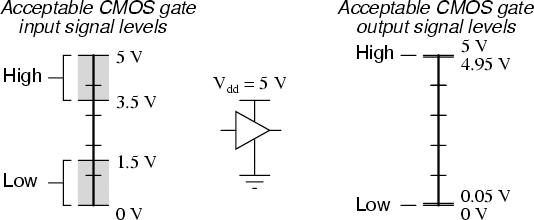

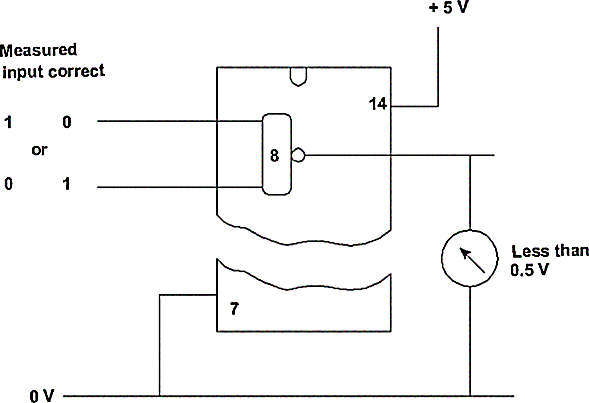

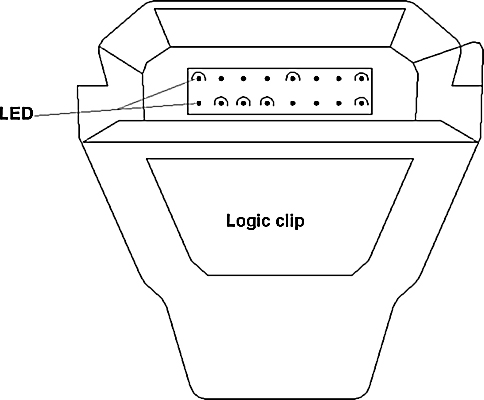

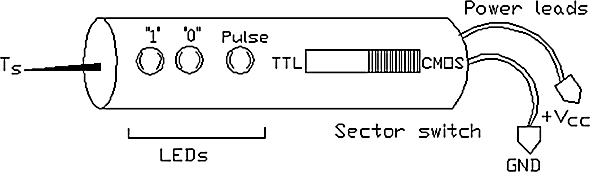

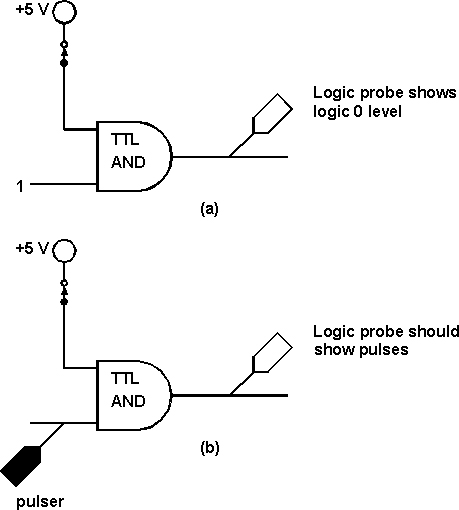

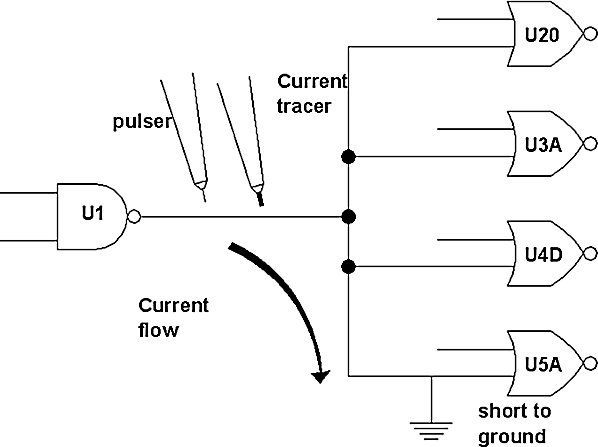

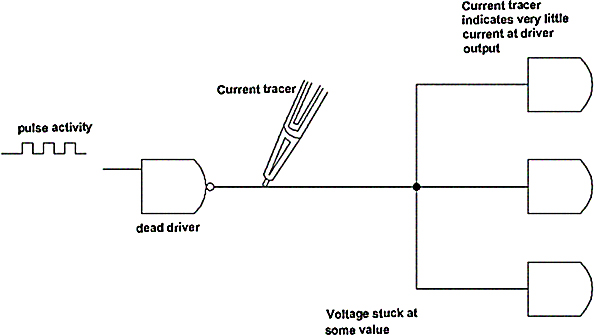

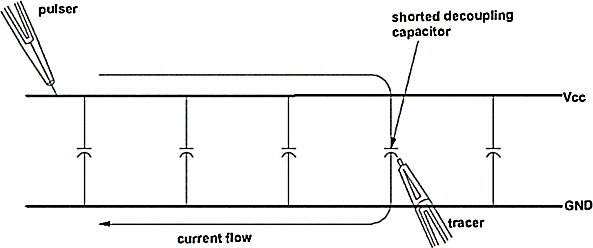

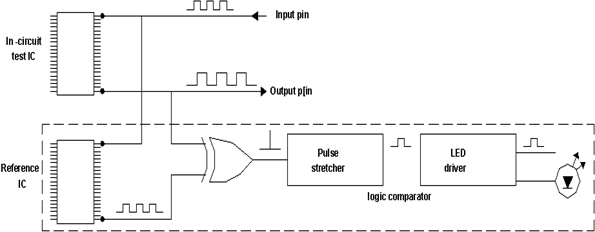

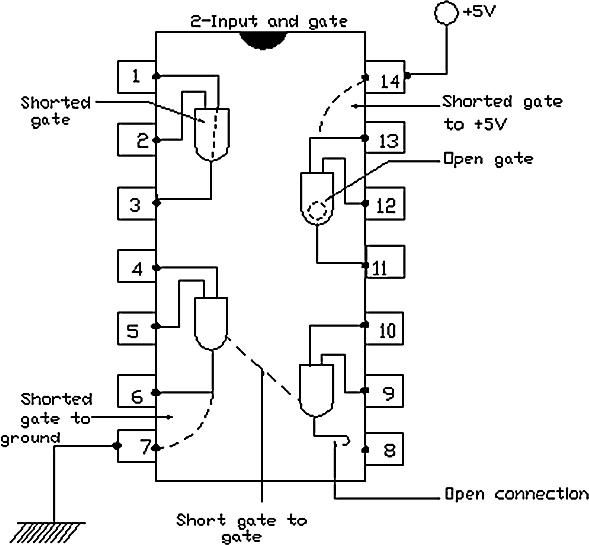

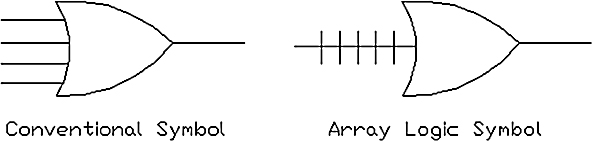

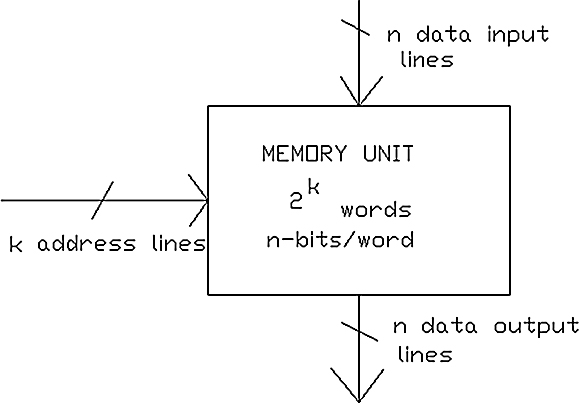

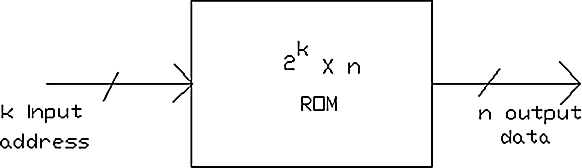

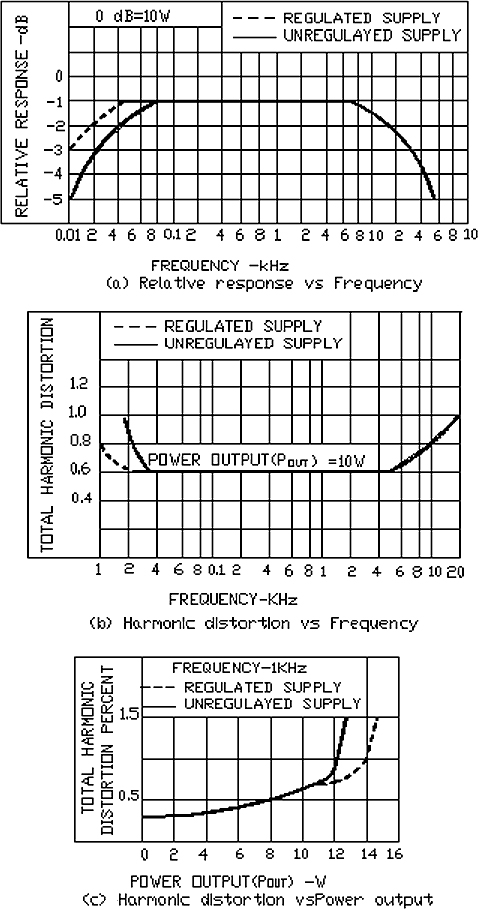

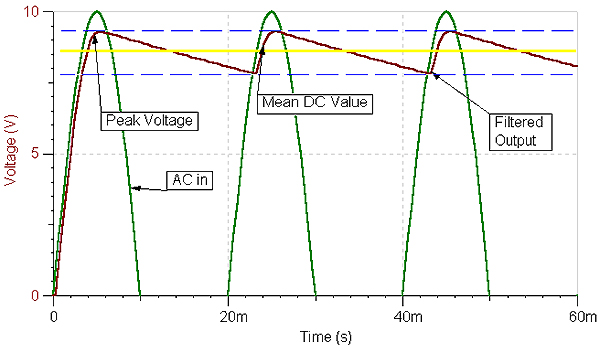

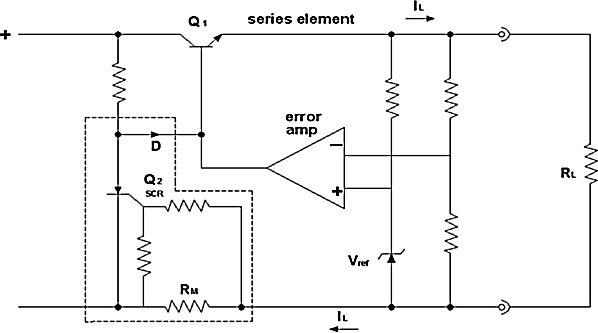

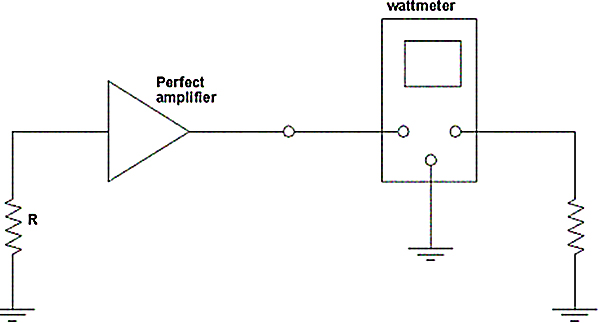

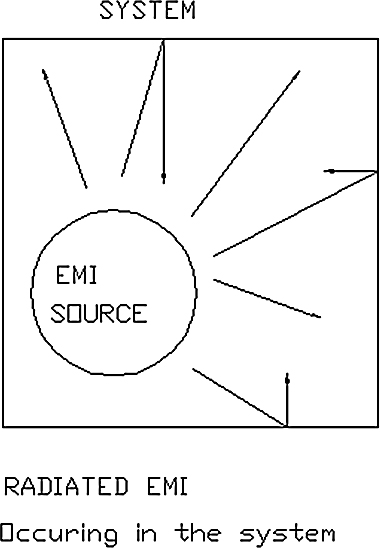

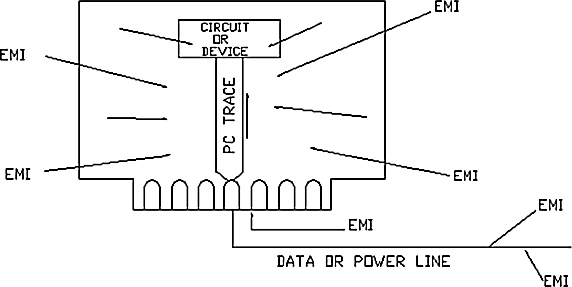

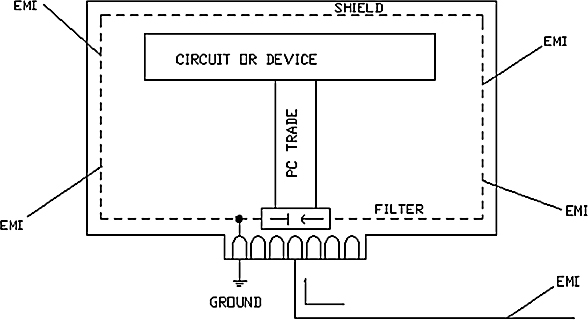

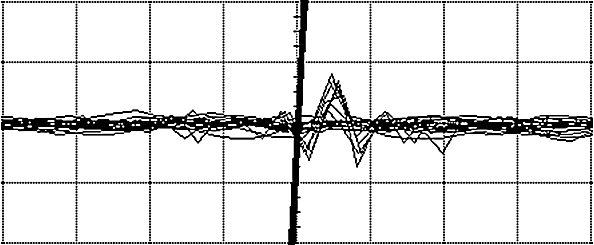

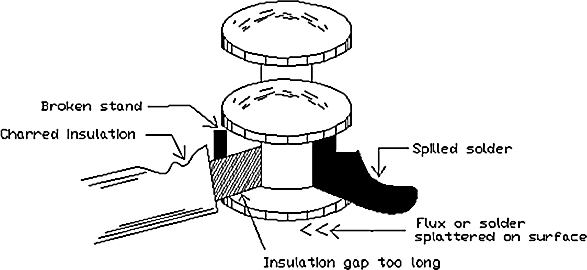

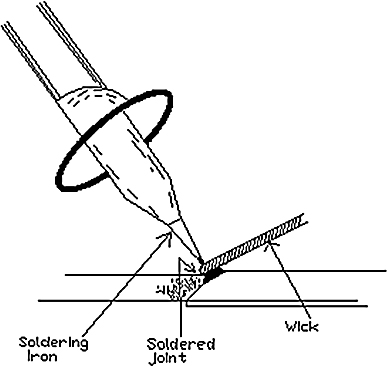

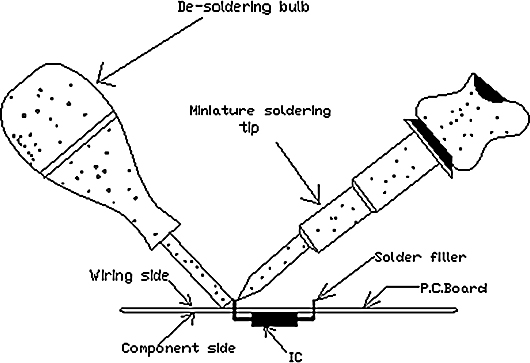

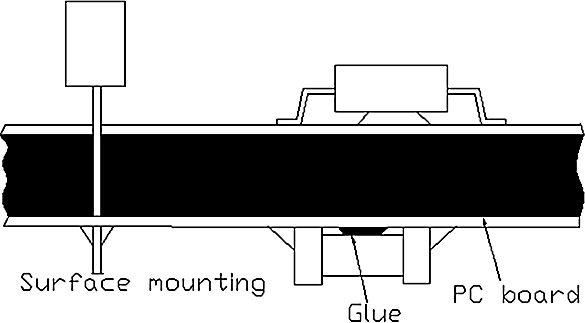

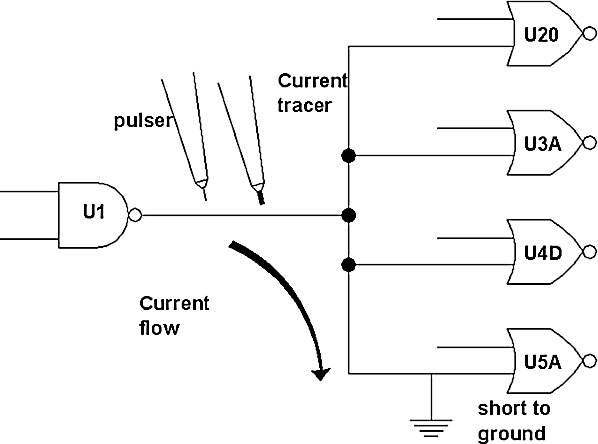

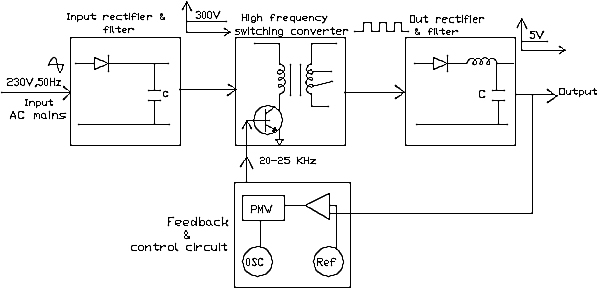

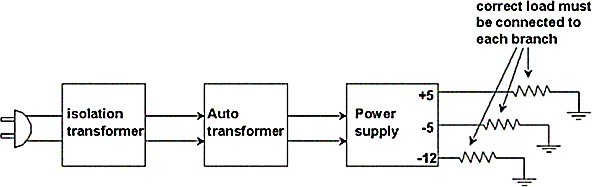

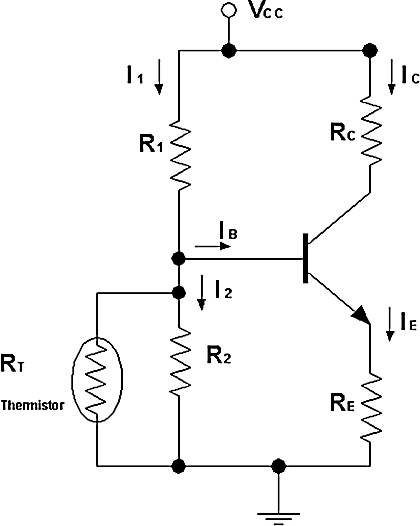

Use fully screened probes at high frequencies to avoid possibility of signal degradation. The use of a compensated probe unit reduces the effect due to amplitude attenuation and phase distortion in a coaxial cable.